Proposed European PFAS ban officially submitted – it’s potential impact on PTFE gaskets.

On the 13 January 2023, The Netherlands, Germany, Denmark, Sweden and Norway took the first formal step towards a European ban on polyfluoroalkyl substances (PFAS) by jointly submitting a restriction proposal to the European Chemicals Agency (ECHA). PTFE, (polytetrafluoroethylene), belongs to a subgroup of PFAS called fluorinated polymers.

Due to PTFE’s durability and general chemical resistance, it is a popular material used as the sealing component in the manufacture of sheet and semi metallic gaskets. Any ban of PFAS could have a serious impact on businesses utilizing PTFE gaskets and businesses need to prepare for any future ban.

PFAS is seen as a forever chemical, which does not naturally break down in nature. Further to PFAS being identified as a forever chemical there is ongoing research to understand whether exposure to PFAS has any impact to our health. This research and evaluation will also be applicable to PFAS sub groups, if there is the potential for PTFE gaskets to cause harm to our health it would be prudent for operators to consider changing from PTFE gaskets to alternative gasket materials.

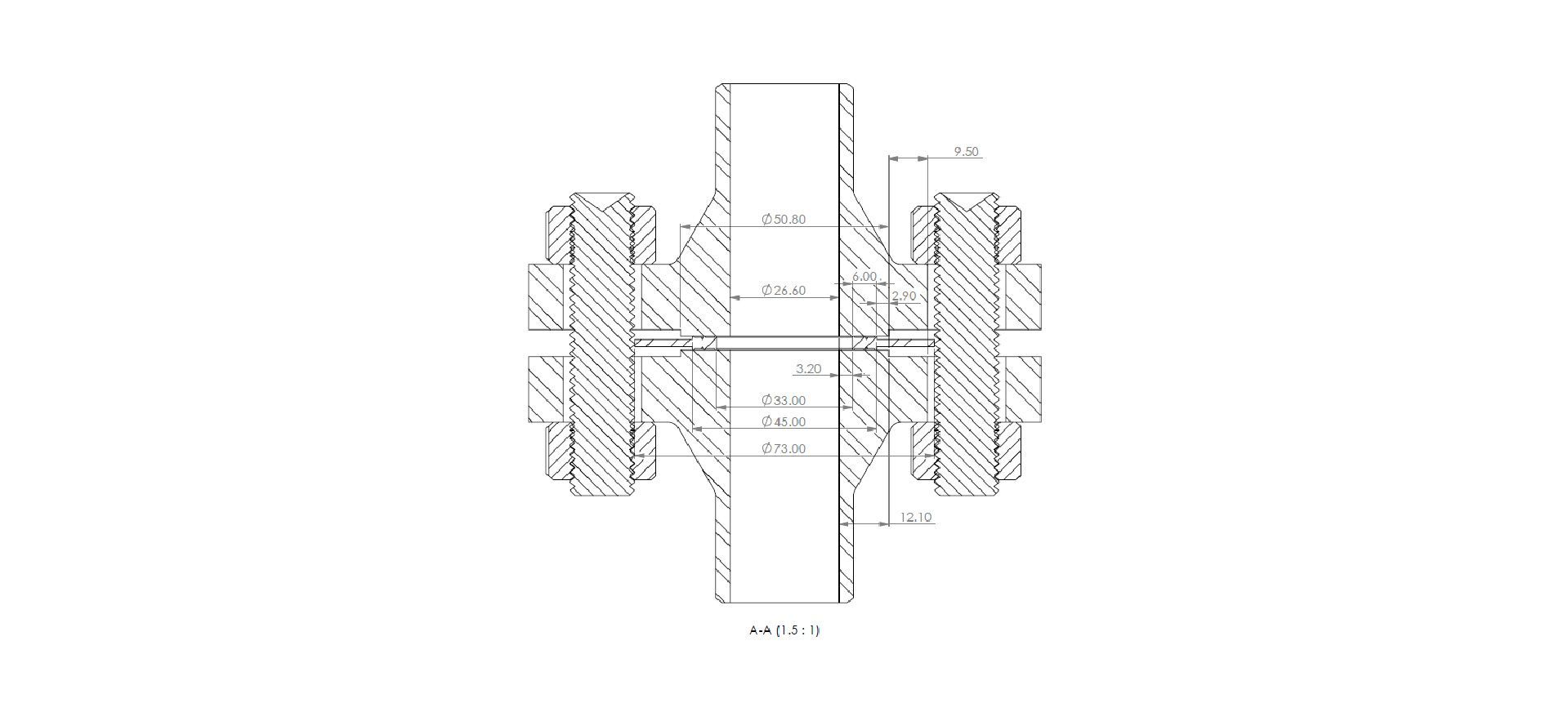

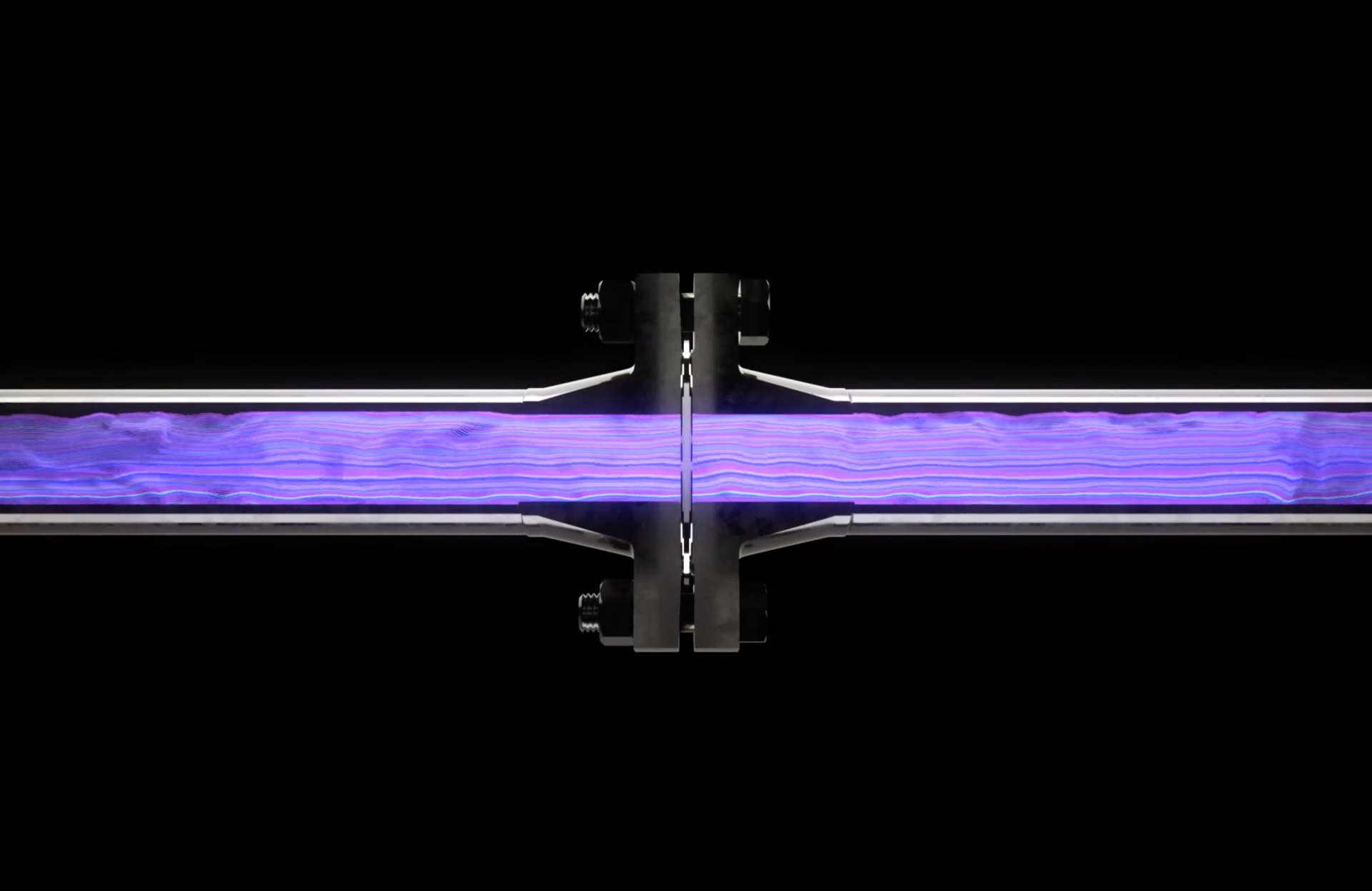

Pipeotech, is a European manufacturer of the DeltaV-Seal flange gasket. Pipeotech precision CNC machine our gaskets from material compatible with the piping. As the patented DeltaV-Seal is fully metallic and without the need for sealing compounds, we can be confident our gasket is PFAS-Free and will not be subject to any future PFAS legislation, application and environmental restrictions.