FPSO & Marine - DeltaV-Seals ensure the safe and reliable operation of inert gas systems

A market-leading expert for the maritime industry manufactures a range of inert gas generators to suit their client's needs. Vessels carrying cargo-producing hydrocarbon vapors require inert gas generators to remove flammable and explosive atmospheres from their cargo tanks.

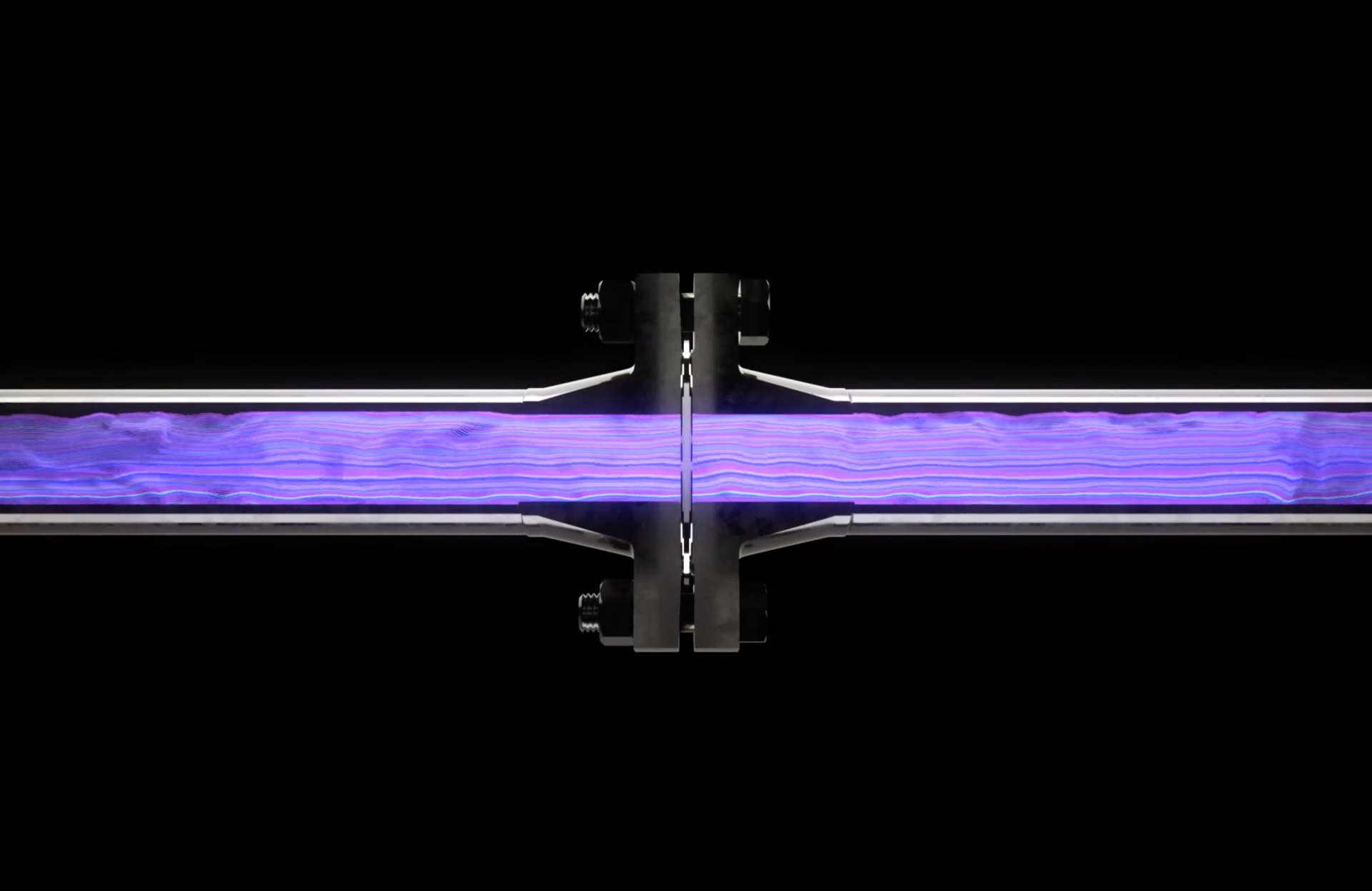

Vessels carrying cargo producing hydrocarbon vapour require an inerting solution to eliminate the risk of explosions and fires in the cargo tanks. This can be achieved by keeping the oxygen content below 8%, a standard set by IMO. The Maritime Protection Inert Gas Generator (IGG) system is a combustion solution that creates inert gas containing oxygen less than 5%.

Industry Challenges

Maritime Protection, a manufacturer of inert gas generators wanted the best available, proven, and approved gasket technology for its natural gas fired inert gas systems. The bolted flange joints in the natural gas piping must be resistant to vibration, maintenance-free, fire resistant, and require no re-torquing of the bolts throughout the joint’s lifetime. The DeltaV-Seal™ was the perfect fit, providing the client with a long-term fire safe gas tight seal.

Background

Vessels carrying cargo-producing hydrocarbon vapors require an inert solution to eliminate the risk of fires and explosions within their cargo tanks. Inert gas generators produce inert gas to reduce oxygen levels within the cargo tanks of FPSOs and other marine vessels. Given the critical nature of the performance of inert gas generators to the safety of ships worldwide, ensuring the reliability and integrity of the bolted flange joints is crucial to ensuring the long-term reliable performance of the inert gas generator.

Benefits

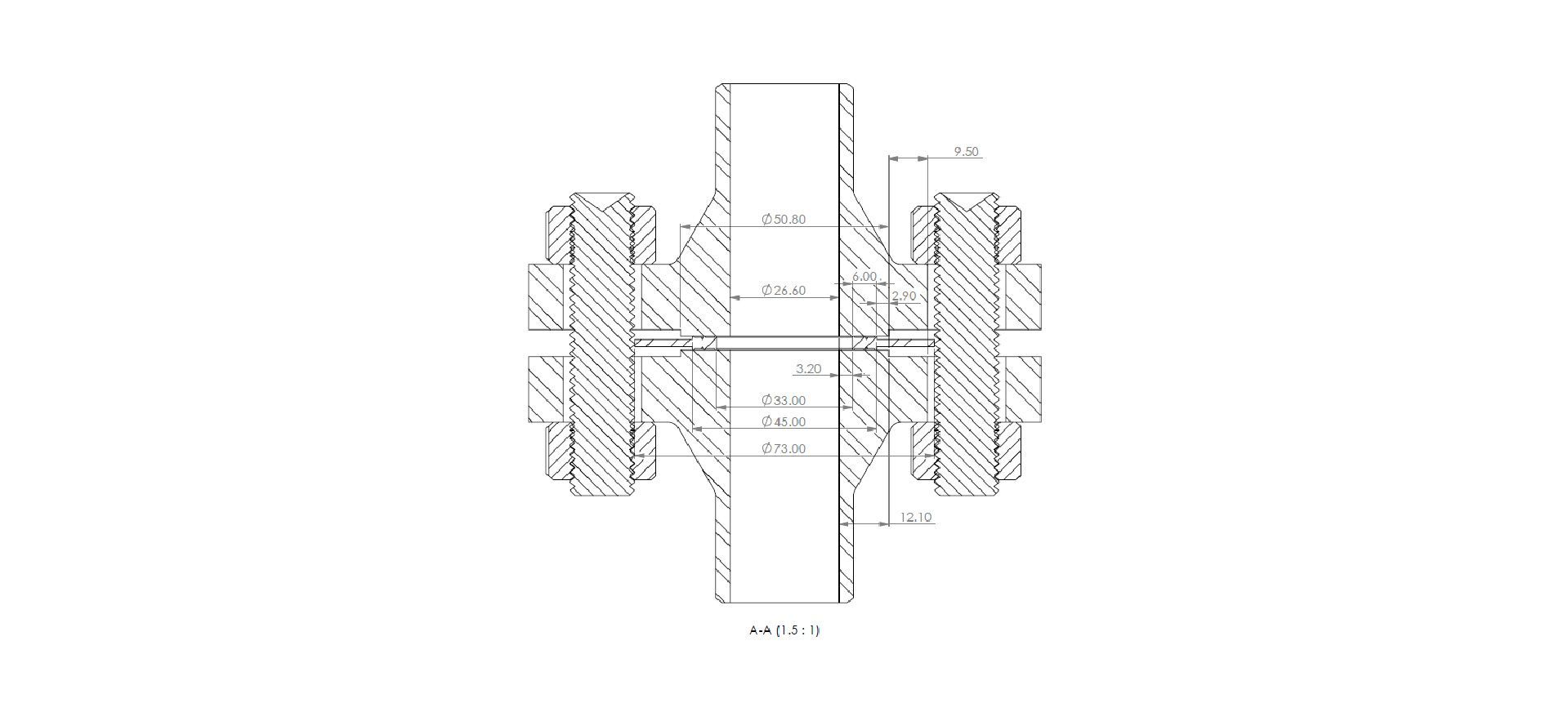

Hundreds of DeltaV-Seal™ flange gaskets have been supplied and installed within the bolted flange joints of the inert gas generators manufactured by the client as the DeltaV-Seal simplifies maintenance with no need to re-torque and proven resistance to vibration loading. Furthermore, the gasket has a known thickness before and after installation; this defined thickness has simplified the design of the piping and flanges within the inert gas generators.

Solutions

Pipeotech’s 316L stainless steel gasket is the perfect fit. The DeltaV-Seal ™ flange gasket is fully metallic, providing the tight and durable metal-to-metal seal the client requires. The gasket does not need re-torquing and has been proven gas-tight by several independent industry tests. Furthermore, the gasket has been tested and proven resistant to pressure and vibration cycles, certified by DNV GL (Certificate TAP000003B). All DeltaV-Seals are certified as fire-safe per API6FB.

Download the full case study

Download the case study by clicking the link below: