DeltaV-Seal - Reducing fugitive emissions in the Permian Basin

The United States Clean Air Act (CAA) is the comprehensive federal law regulating emissions from stationary and mobile sources.

Among other things the CAA authorises the United States Environment Protection Agency (EPA) to establish National Ambient Air Quality Standards (NAAQS) to protect the public health and public welfare as well as regulate emissions of hazardous air pollutants. The DeltaV-Seal effectively removes fugitive emissions fugitive emissions from connections, this case study details how.

Background

A report by the EPA (EPA-453/R-95-017) highlighted that the percentage of fugitive emissions coming from connectors (including bolted flange joints) accounts for 31% of emissions within a typical refinery or chemical plant.

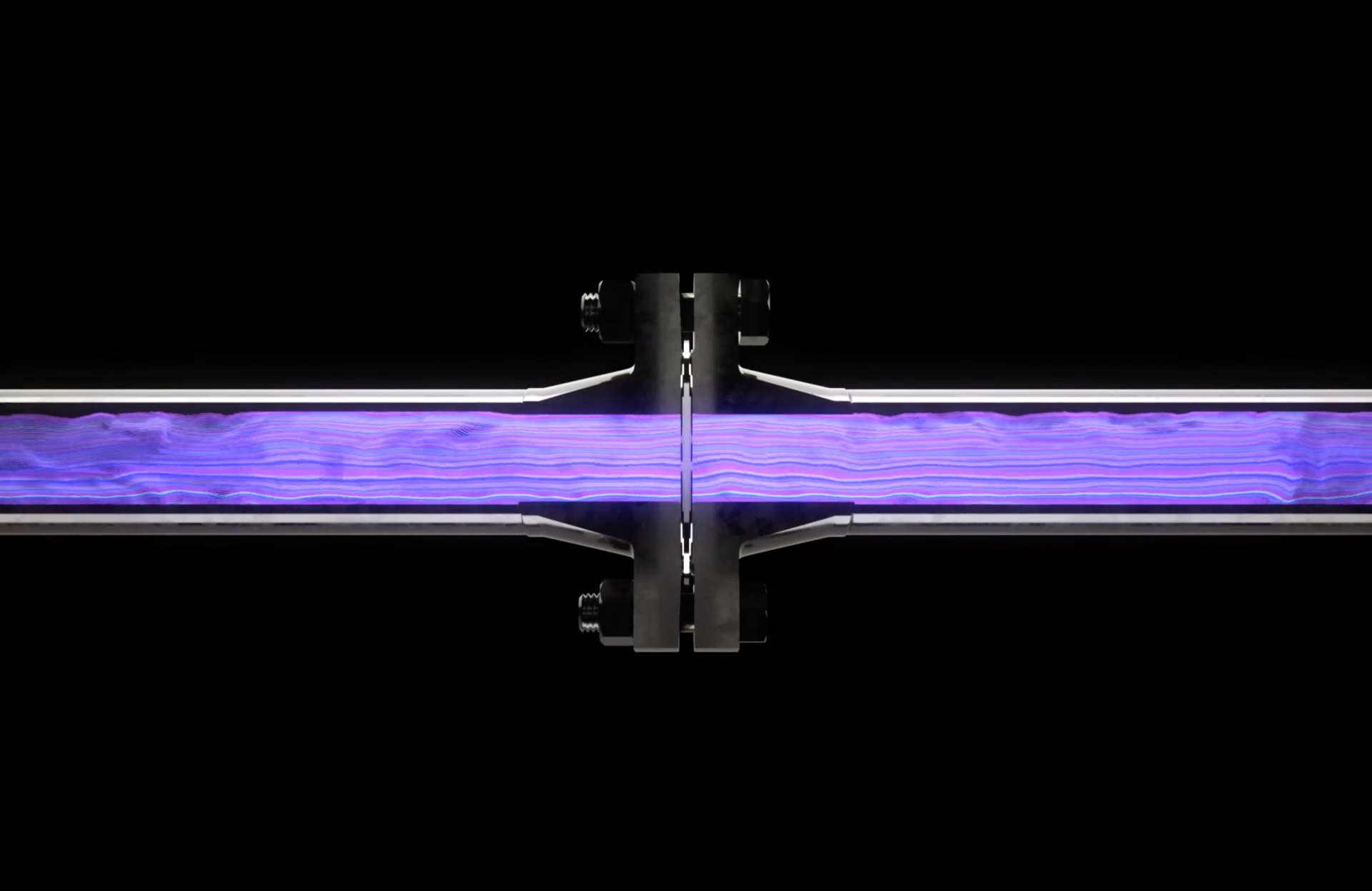

The simplest way for an operator to reduce emissions by nearly a third and help avoid fines would be to stop emissions from connectors. The DeltaV-Seal flange gasket is precission engineered to provide a tight and durable seal , ensuring effectively zero fugitive emissions for the lifetime of a bolted flange joint.

Industry Challenges

Legacy gasket technologies leak, this leakage rate only increases as the installed gaskets degrade with time. With the EPA having the power to fine operators for their emissions using the Clean Air Act, any effort made to reduce emissions can help operators a void fines.

Operators schedule turn-arounds to change gaskets and maintain equipment. As technology advances, equipment becomes more reliable with greater available uptime. As equipment becomes more reliable the gasket can become the weak point in the system, increasing emissions or leading to unplanned shut downs, now resulting in emissions fines relating to the CAA.

Solutions

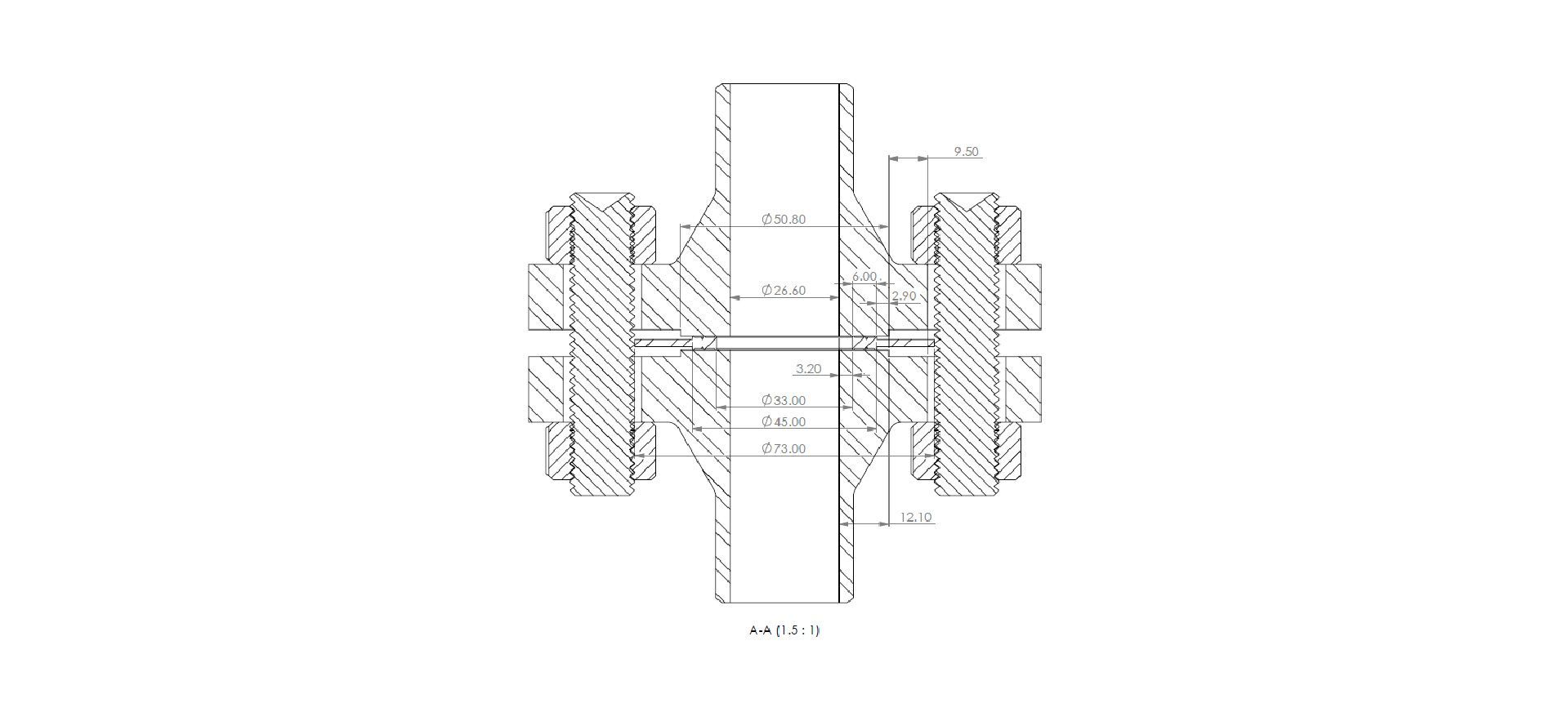

Metal-to-metal seals are proven to be tight and durable for decades . However, traditional (RTJ) fully-metallic seals are known to damage flanges and be sensitive to installation conditions, including surface roughness. The DeltaV-Seal has been expertly engineered, independently tested, and is precision machined to provide the tightness and durability of a metal-to-metal seal, with the ease of use and installation of traditional semi-metallic gaskets .

The DeltaV-Seal is suitable for use on ASME B16.5 raised face and flat face flanges, without causing damage to the flange face. The DeltaV-Seal provides industries with a metal-to-metal seal which is simple to install, durable for the lifetime of the bolted flange joint, and able to help operators prevent fines for fugitive emissions . No additional considerations are required compared to traditional semi-metallic gaskets.