Reduce your VOC emissions with the DeltaV-Seal™

Globally there is a drive to consume less and emit fewer damaging chemicals into the atmosphere. Within the United States, businesses are being called to reduce fugitive emissions by at least 30% before 2030.

There is a further global push for all countries to be net-zero emissions by 2050. The DeltaV-Seal™ has the potential to assist businesses in reducing their emissions and remaining compliant with their local laws meeting climate targets and improving their ESG Score Card value.

The United States Environmental Protection Agency (EPA) determined that leaking equipment, such as valves and connectors, is the largest source of volatile organic compound (VOC) emissions from petroleum refineries and chemical manufacturing facilities (EPA, 2007).

VOCs include many industrial chemicals such as benzene and solvents such as toluene and xylene (NJDEP New Jersey Department of Environmental Protection, n.d.). When leaked into the atmosphere, these chemicals create long-term climate effects. In the past, these emissions have not been well regulated, so the EPA implemented a program to promote the reduction of emissions (EPA, 2007).

– The EPA has estimated that approximately 70,000 tons of VOCs are emitted yearly from leaks contributing to smog formation (EPA, 2007).

United States Environmental Protection Agency, 2007

Companies are required to reduce their VOC emissions through the Leak Detection and Repair (LDAR) program. LDAR regulation programs require companies to make equipment modifications and conduct regular monitoring to prevent leaks. With the proper implementation, companies are expected to reduce up to 96% of their emissions. Pipeotech's experience is that these programs can be costly to implement and only serve as short-term solutions given the degradation in performance of bolted flange joints sealed with traditional gaskets.

– 31% of uncontrolled VOC emissions in a petrochemical plant come from connectors (EPA, 2007).

United States Environmental Protection Agency, 2007

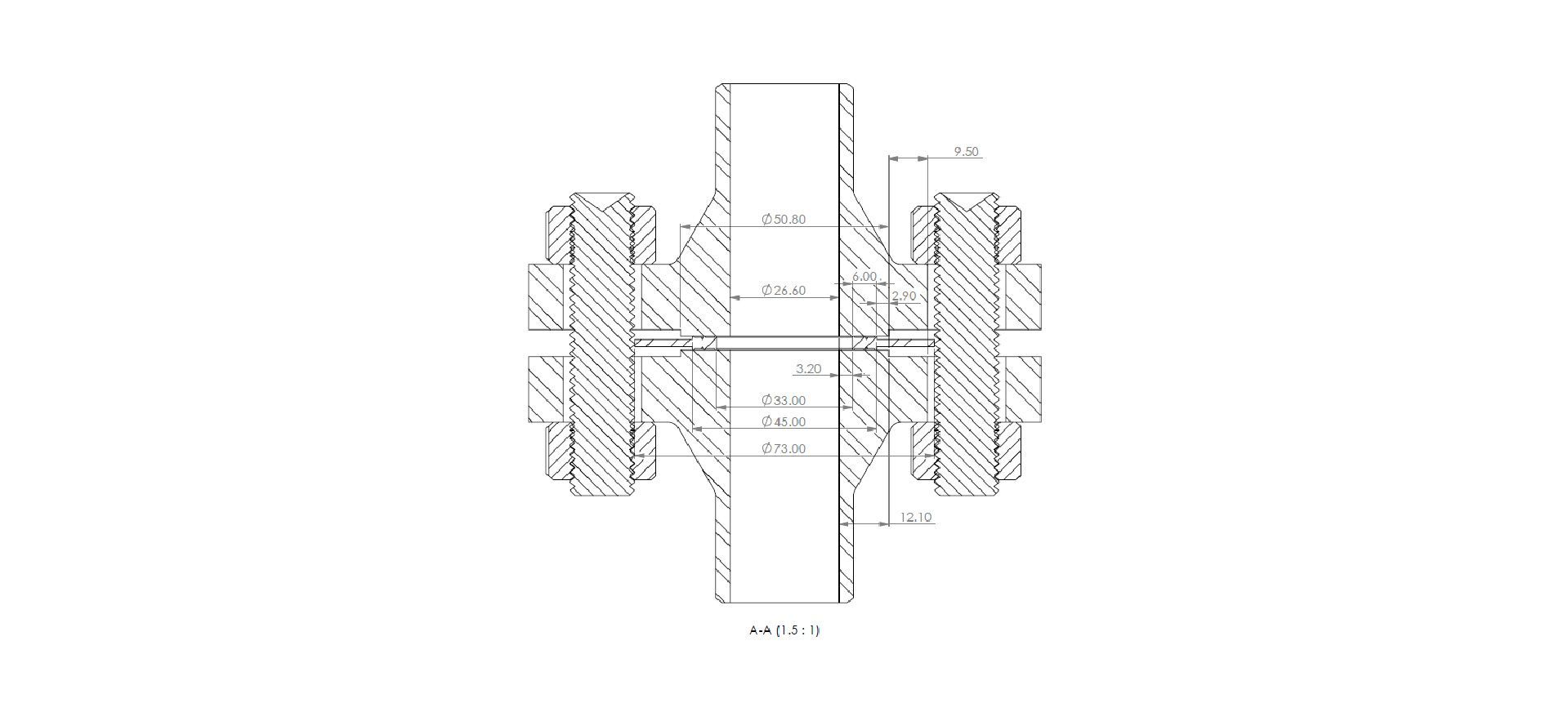

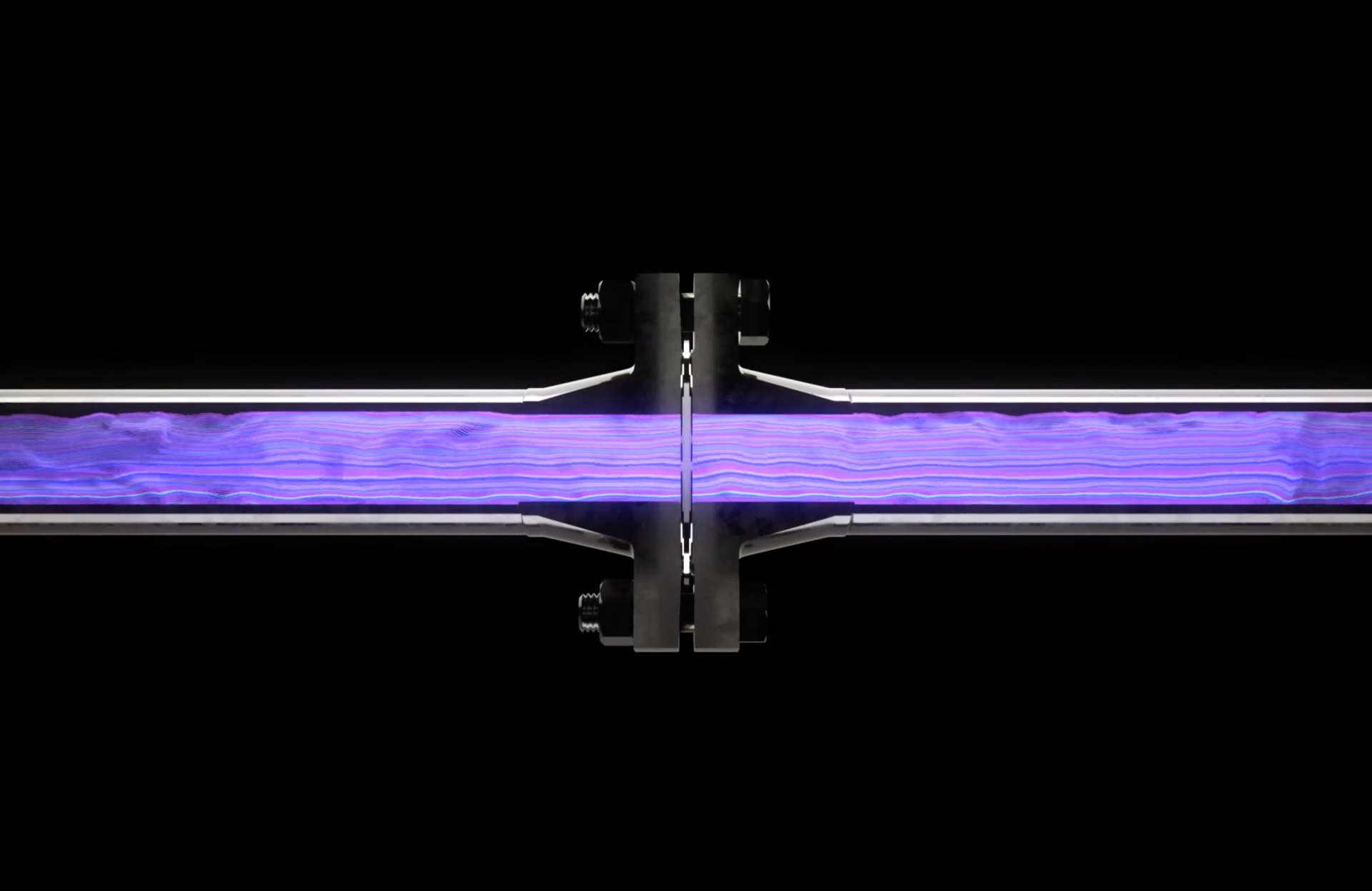

PIPEOTECH offers a different solution while still maintaining LDAR compliance. Installing the DeltaV-Seal™, a fully metallic sealing flange gasket, into bolted flange joints can significantly reduce these emissions with a gas-tight seal, which has been subject to stringent 3rd party testing at temperatures between -196 °C and +880 °C (-320 °F and 1616 °F). Utilising the DeltaV-Seal™ ensures gas-tight sealing, technically tight, durable, long-term, and superior sealing performance that helps operators to meet their emissions targets and improve their ESG Score Card value.

In addition to reducing emissions from bolted flange joints and helping businesses meet their target climate goals, the DeltaV-Seal™ flange gasket has been proven time and time again to reduce significantly overall maintenance costs, eliminate unplanned shutdowns and improve overall HSE TRIR numbers.

Not only can we assist businesses in removing emissions Pipeotech can also increase reliability and reduce costs.