Replacing legacy gasket technology to increase reliability and reduce maintenance costs

Fertilizers are critical to enable the growing global population to be fed. Ongoing increases in energy prices, particularly methane, have made the cost of manufacturing nitrogen and ammonia-based fertilizers particularly high.

Anything a manufacturer can do to reduce costs, reduce NOX emissions, and increase reliability has a positive global impact, ensuring a secure and long-term food supply while at the same time increasing reliability and reducing maintenance costs.

Background

A manway to a heater within a fertilizer facility in Europe had previously been sealed with a tanged gasket sheet. Every four to six weeks excessive NOX emissions would be detected in the area surrounding the manway (in Europe emissions are limited to 90 PPM).

Further investigations found that Thermiculite gasket was degrading causing leaks of NOX gas. The leaking Thermiculite gasket was causing frequent unplanned maintenance outages to replace the gasket. The regular unplanned maintenance stops would have a negative impact on the profitability and reliability of the fertilizer plant.

Industry Challenges

Legacy semi-metallic gasket technologies leak, this leakage rate only increases as the installed gaskets degrade with time. The leakage of NOX gas has a severe impact on the local environment and is considered an indirect greenhouse gas. In the United States the Environment Protection Agency has reduced NOX emissions from a maximum 3000 PPM down to 200 PPM.

In the European Union, the maximum is 90 PPM. As a result, NOX leakages must be stopped swiftly. Technology that prevents emissions and is proven dependable has a key part to play in slowing climate change and increasing the reliability of existing fertilizer facilities, while reducing fines for NOX emissions.

DeltaV-Seal keeps industry reliable

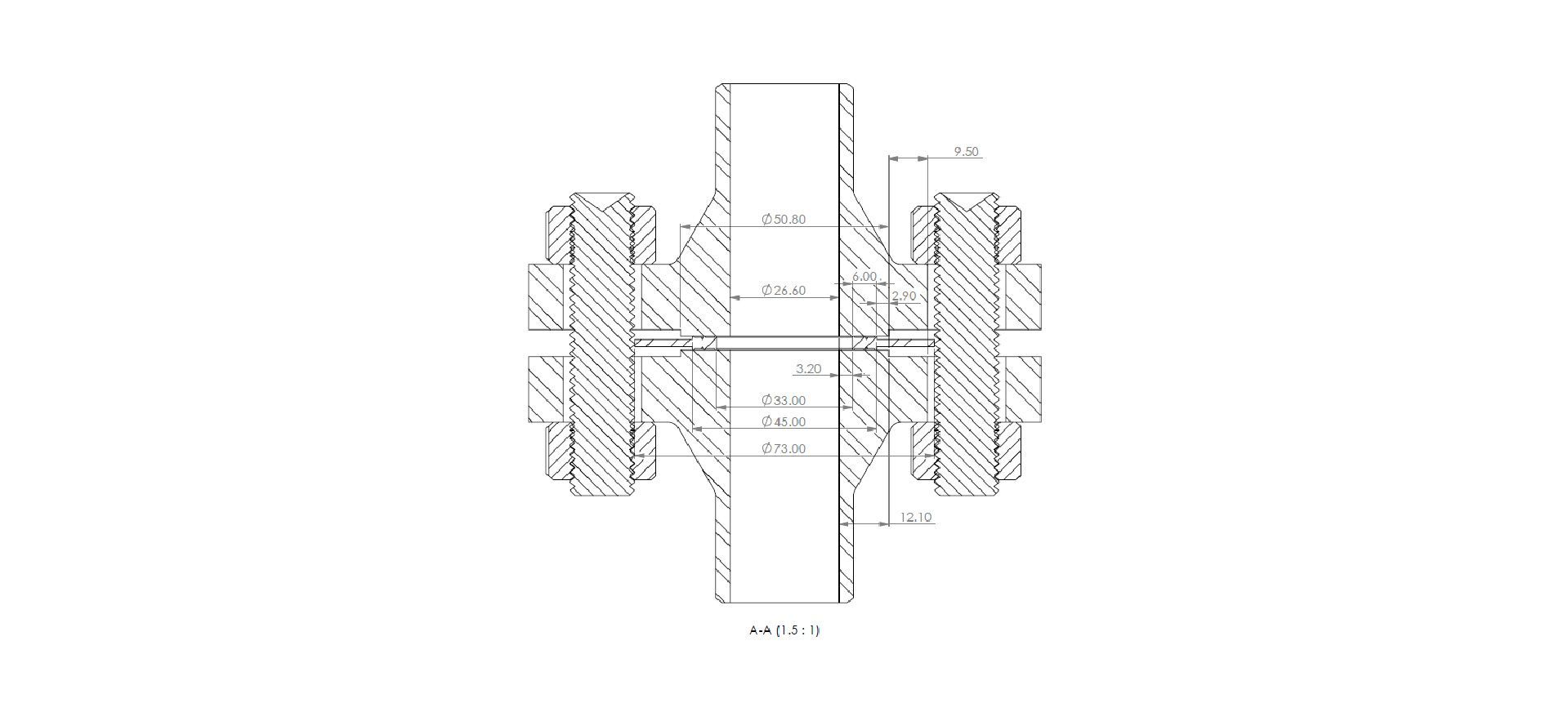

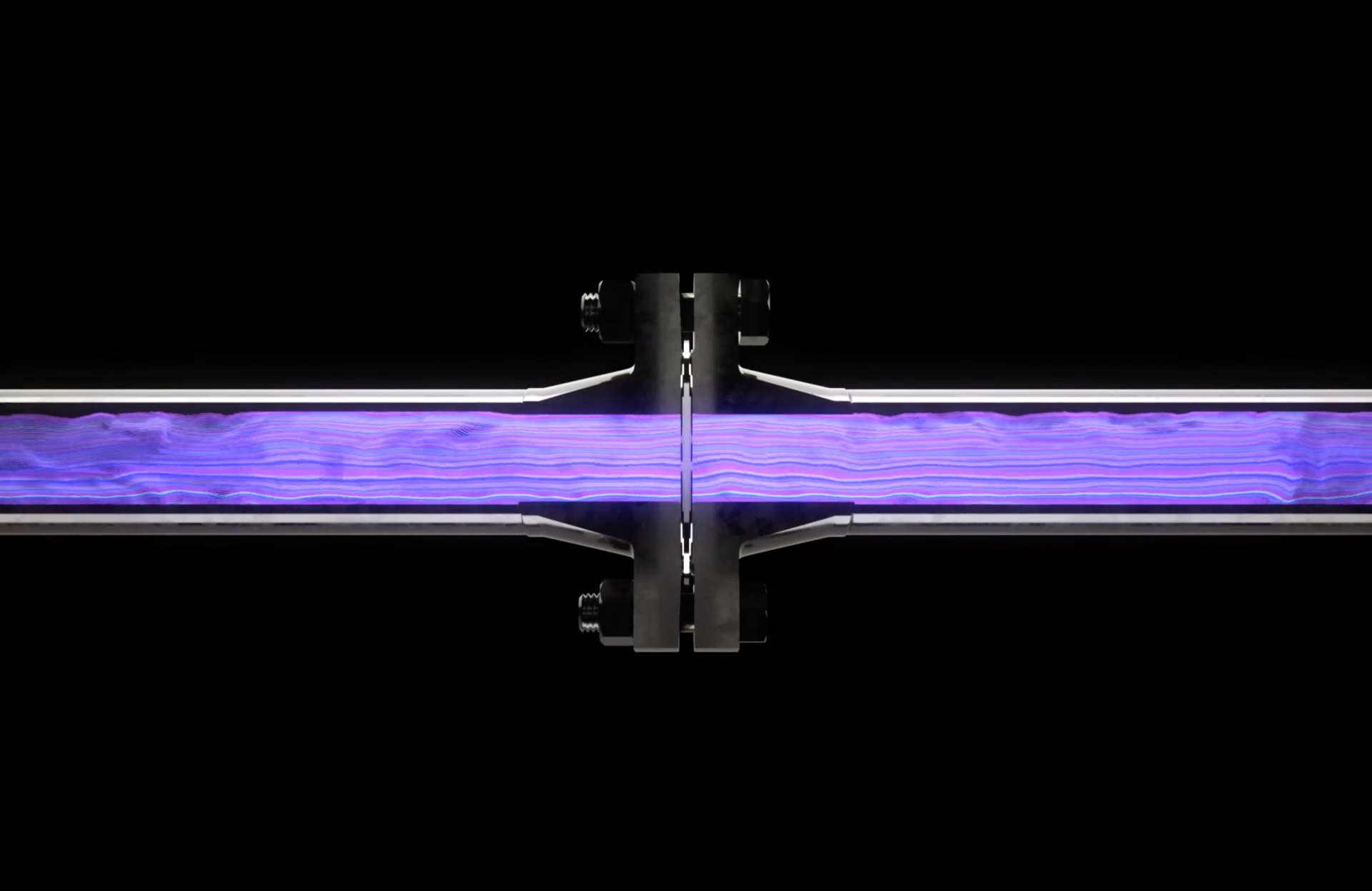

All gaskets leak, some more than others. Industry knows the best seal is a metal-to-metal seal. Traditional (RTJ) fully-metallic seals are known to damage flanges and be sensitive to installation conditions, including surface roughness. The DeltaV-Seal is different to legacy metallic seals, it is precision CNC machined from a single metal plate to ensure a tight and durable seal which does not damage flanges.

The DeltaV-Seal’s installation requirements are the same as a semi-metallic gasket, following the guidelines ASME PCC1 Appendix D. With the DeltaV-Seal being manufactured from a similar, compatible material to that of the piping / vessel its chemical resistance is the same or similar.

Solutions

Metal-to-metal seals have proven to be tight and durable for decades. The DeltaV-Seal has been expertly engineered and independently tested in the lab and field to demonstrate its superiority to traditional legacy gasket technology. In this specific case, where the precision engineered 304L DeltaV-Seal has replaced a Thermiculite tanged gasket sheet the DeltaV-Seal provides effectively-zero NOX emissions while improving plant reliability.

By simply changing to the DeltaV-Seal the facility will have less unplanned shutdowns, save significantly on maintenance costs, while at the same time reducing emissions of an indirect greenhouse gas. Why use legacy technology when new proven technology increase’s reliability while reducing costs?

Download the full case study

Download the case study by clicking the link below: