Replacing legacy semi-metallic gasket technology to prevent emissions of hazardous chemicals

Ammonium Nitrate is a challenging chemical to seal, in addition to being extremely hazardous. When Ammonium Nitrate emissions escape from bolted flange joints it crystalizes.

These crystals of Ammonium Nitrate are a safety hazard and undesirable. Further to this the Ammonium Nitrate crystals can form inside the pipe, reducing flow and productivity. To remove the crystals of Ammonium Nitrate inside the piping, steam cleaning is utilized. This increases the degradation of legacy semi-metallic gaskets leading to an increased leakage rate, which results in more emissions, more crystals, and a cycle of avoidable costly maintenance.

Background

A major European fertilizer manufacturer had become aware of the successes the DeltaV-Seal was having within a competing manufacturers facility. Having similar challenges with Ammonium Nitrate crystals forming around their bolted flange joints, the facility operator was keen to test the DeltaV-Seal gasket in 4 bolted flange joints on their Ammonium Nitrate system.

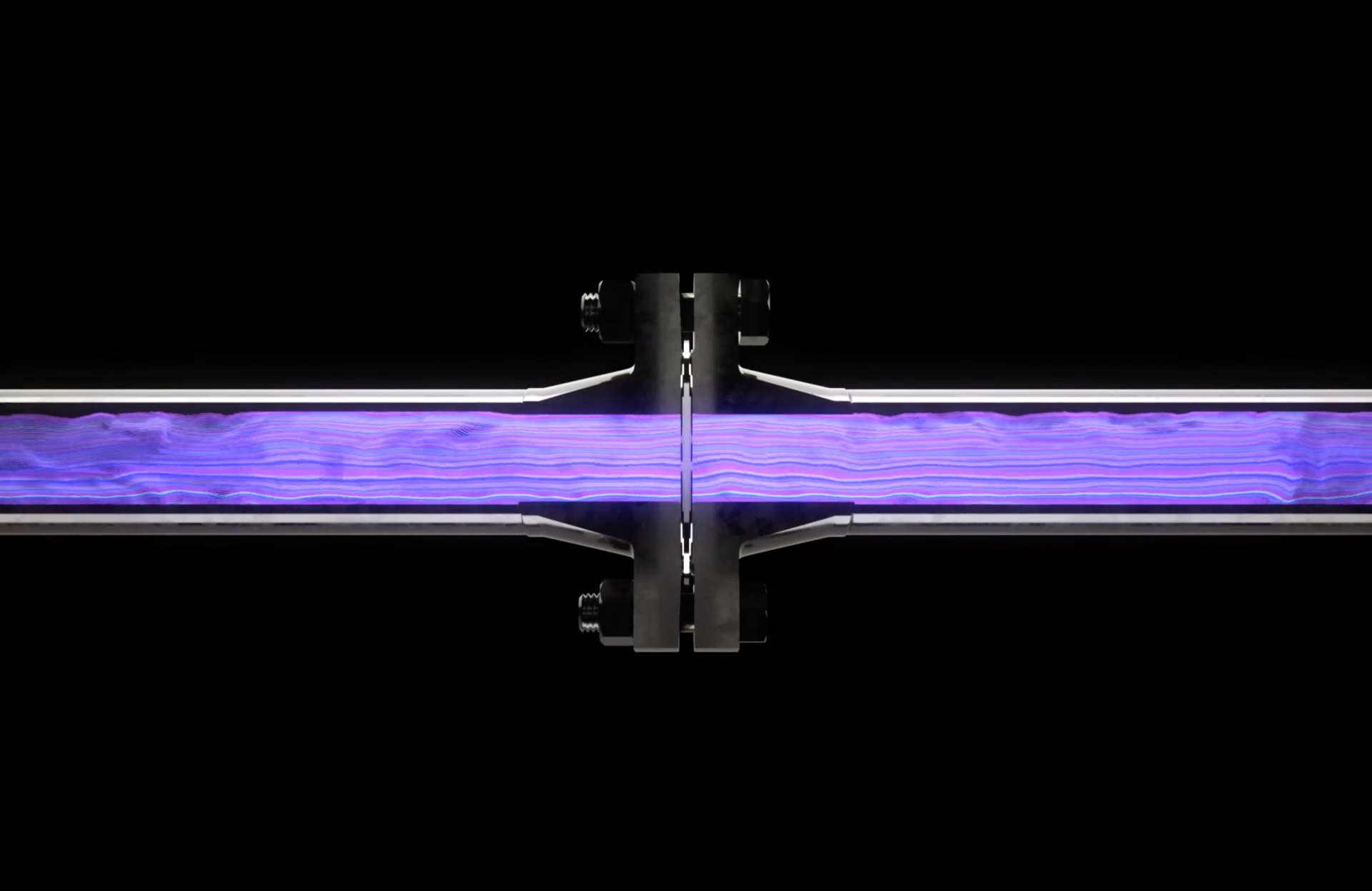

The DeltaV-Seal was of particular interest due to its extremely low leakage rate, preventing the emissions and crystallisation of Ammonium Nitrate from bolted flange joints, breaking the cycle of costly maintenance and high emissions from semi-metallic legacy gaskets.

Industry Challenges

With the recent increases in the cost of methane, the cost of producing Ammonium Nitrate has increased significantly. With Ammonium Nitrate being extremely hazardous, proven new technology that breaks the need for regular maintenance of bolted flange joints improves safety, increases reliability, and reduces maintenance costs.

DeltaV-Seal keeps industry safe

All gaskets leak, some significantly more than others. The leakage rate of the previously utilized spiral-wound semi-metallic gaskets had led to deposits of Ammonium Nitrate crystals around the bolted flange joints. With Ammonium Nitrate being a hazardous chemical, these crystals were undesirable so a solution to prevent them was viewed favourably by the facilities operator.

With the DeltaV-Seal being well proven, a management of change process was completed between the plant operator and Pipeotech to ensure the successful and correct installation of the gaskets. The installation torque values are similar to that of semi-metallic gaskets, and the installation follows the same guidelines from ASME PPC1 Appendix D. Once the DeltaV-Seal gaskets had been installed there were no deposits of Ammonium Nitrate around the bolted flange joints.

Solutions

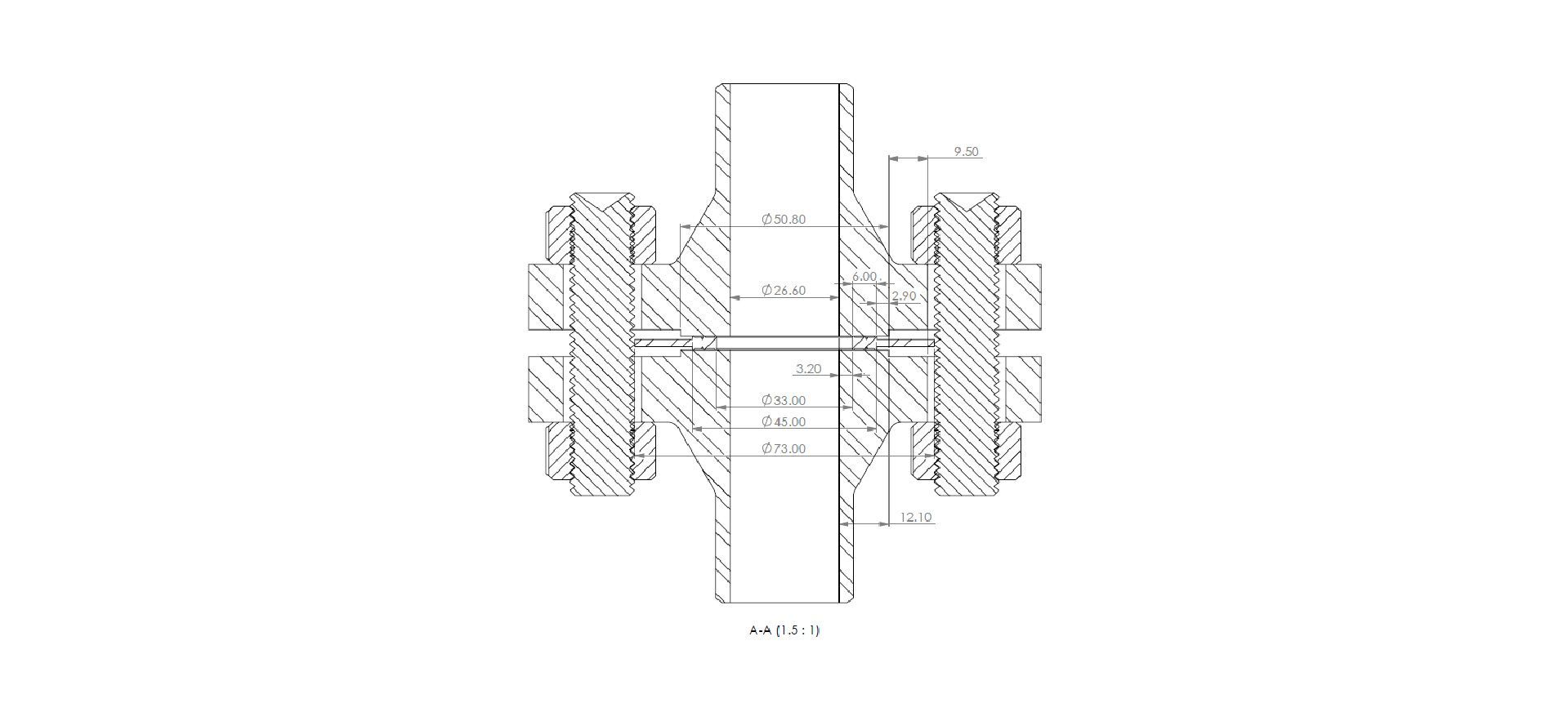

Metal-to-metal seals are proven to be tight and durable for decades. The DeltaV-Seal has been expertly engineered, independently tested, and is precision machined to provide the tightness and durability of a metal-to-metal seal, with the ease of use and installation of traditional semi-metallic gaskets.

In this specific case the Ammonium Nitrate was successfully sealed without any crystallisation observed around the flange. The test was considered a success, and the DeltaV-Seal will be adopted onto the site for Ammonium Nitrate service.

Download the full case study

Download the case study by clicking the link below: