Preventing nitrous gas leakage at a Thermowell instrument flange joint

On a Thermowell instrument coupling flange joint a previous semi-metallic gasket required maintenance intervention 7 times in three-and-a-half years. Switching from a semi-metallic gasket to the DeltaV-Seal prevents the emissions of NOx, protecting the environment and will saving the operator the cost of regular maintenance interventions.

Industry Challenges

Elevated temperatures, corrosive environments, and vibrations may be challenging for semi-metallic gasket technologies. Before the utilization of the DeltaV-Seal™, the previous tanged sheet gaskets required seven unplanned maintenance interventions in three and half years. Ensuring a reliable seal at elevated temperatures, corrosive piping contents, and vibrations from nearby compressors can be a challenge for legacy gasket technologies, while the DeltaV-Seal™ has proven itself capable of working effectively under these plant operational conditions.

Background

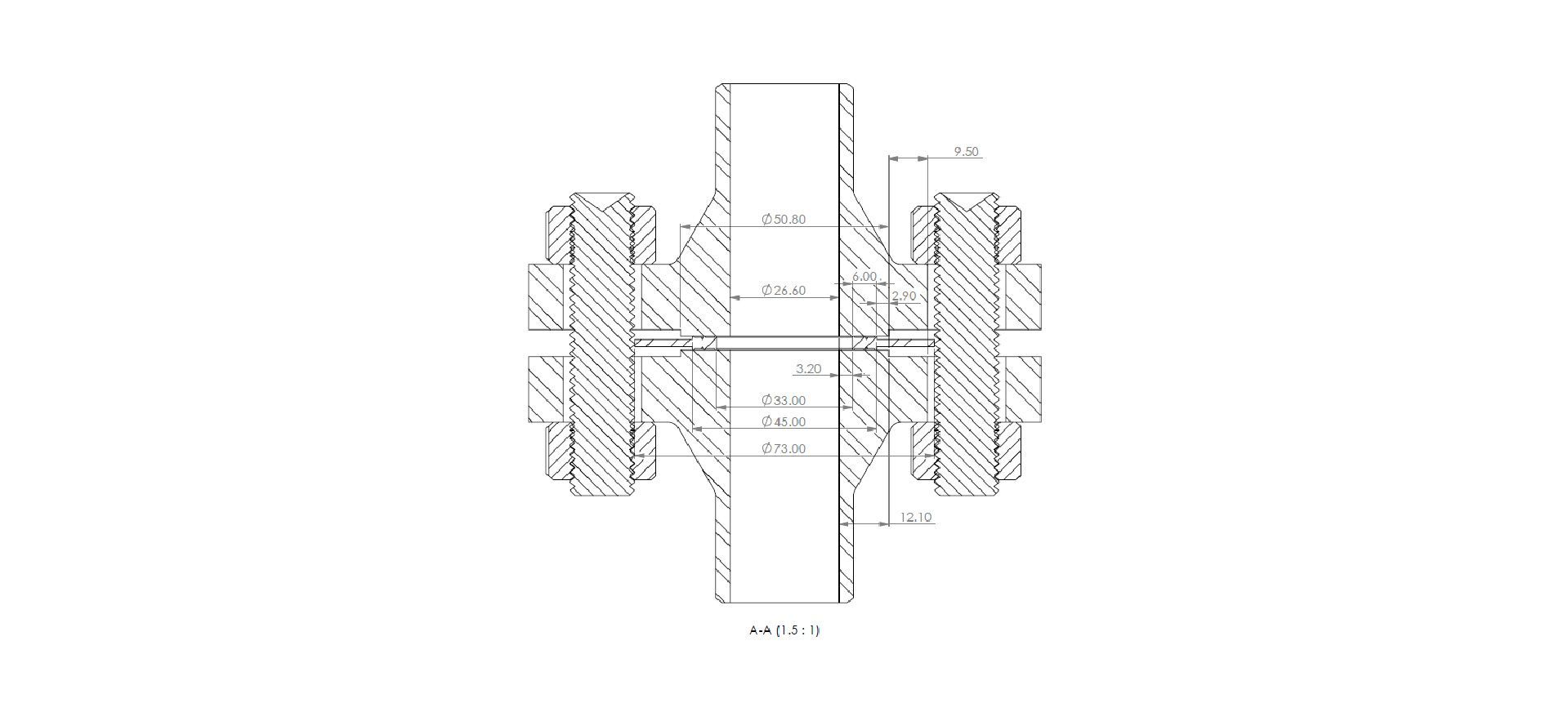

A traditional tanged gasket (shown above) was used to seal an uninsulated Thermowell instrument flange joint (cold spot) in an otherwise insulated piping adjacent to gas compression, causing leakage in a gasketed flange joint. The piping contained nitrous gases and was therefore monitored for fugitive emissions of NOx (NO + NO2) and for pollution in the vent stack.

As the Thermowell instrument was installed adjacent to a gas compressor, the pipework was monitored for vibrations during the plant’s operation. The operational conditions at the flange joint led to frequent shutdowns and the need to replace the gasket.

Benefits

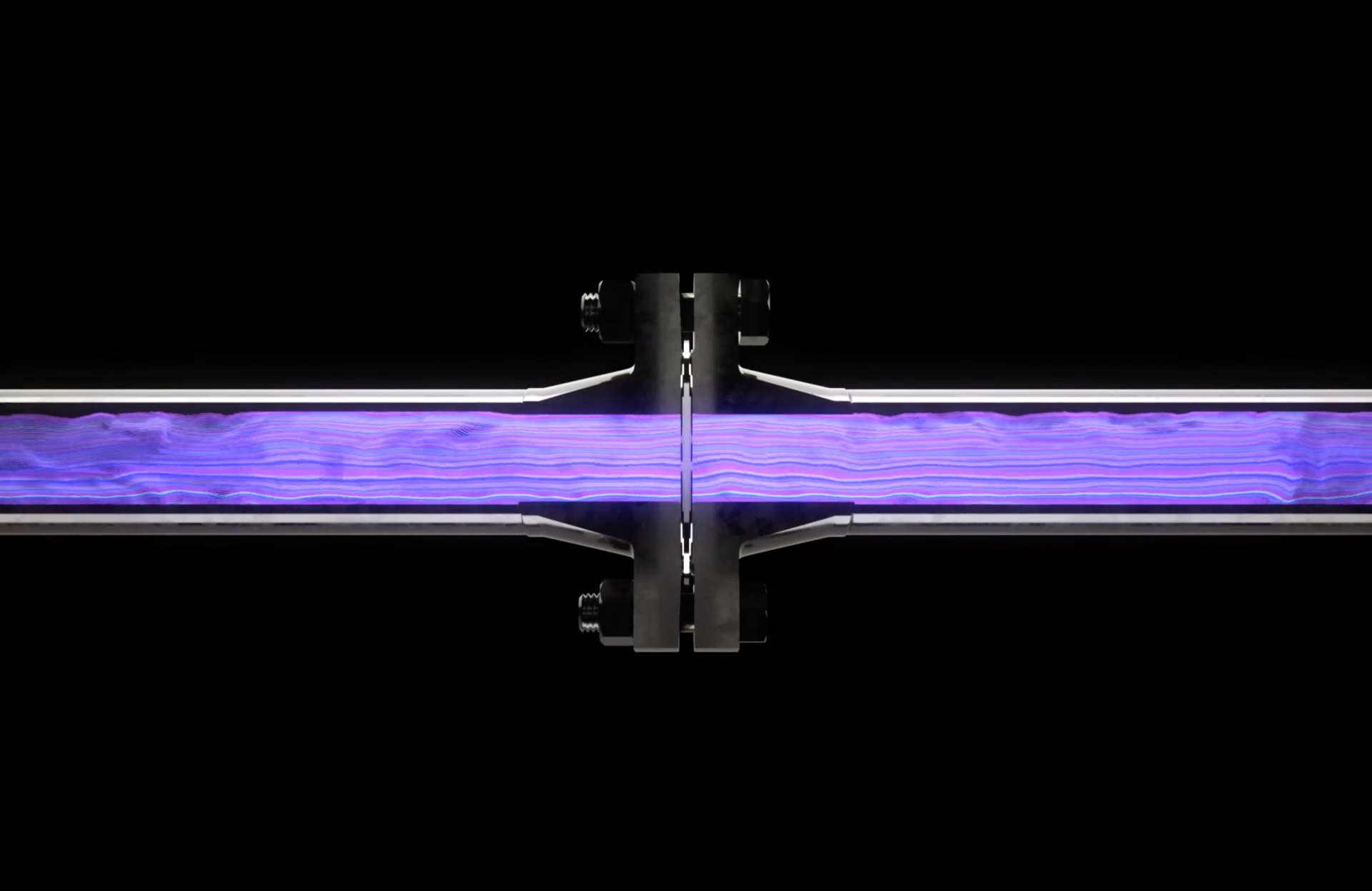

The DeltaV-Seal™ is proven as gas-tight, minimizing fugitive emissions of NOx under challenging piping operational conditions. Being manufactured in materials compatible with the piping and pipe contents, the DeltaV-Seal™ will not be subject to mechanical and chemical degradation as found with semi-metallic gaskets.

With the proven vibration, chemical and pressure pulse resistance, the DeltaV-Seal™ has maintained a gastight seal, improving the fertiliser plant’s reliability. The regular and unplanned maintenance interventions are now prevented by switching from tanged sheet gaskets to the DeltaV-Seal.

Solutions

Pipeotech’s 316L stainless steel gasket is perfect for nitrous gas piping at elevated temperatures, under piping vibrations and in corrosive conditions. The DeltaV-Seal™ gasket is fully metallic, providing the tight and durable metal-to-metal seal that the client required without any special considerations beyond those of traditional semi-metallic gaskets and within the installation parameters of ASME PPC-1 and Pipeotech’s installation instructions.

As the gasket is fully metallic, it removes the need for filler material, thereby preventing degradation over time. Furthermore, the gasket has been tested and proven resistant to pressure and vibration cycles.

Download the full case study

Download the case study by clicking the link below: