DeltaV-Seal™ reduces greenhouse emissions

In fertilizer production, high-quality phosphorus fertilizers require nitric acid as a key ingredient, which is usually synthesized via the Ostwald process on-site (oxidizing of ammonia before combining with water).

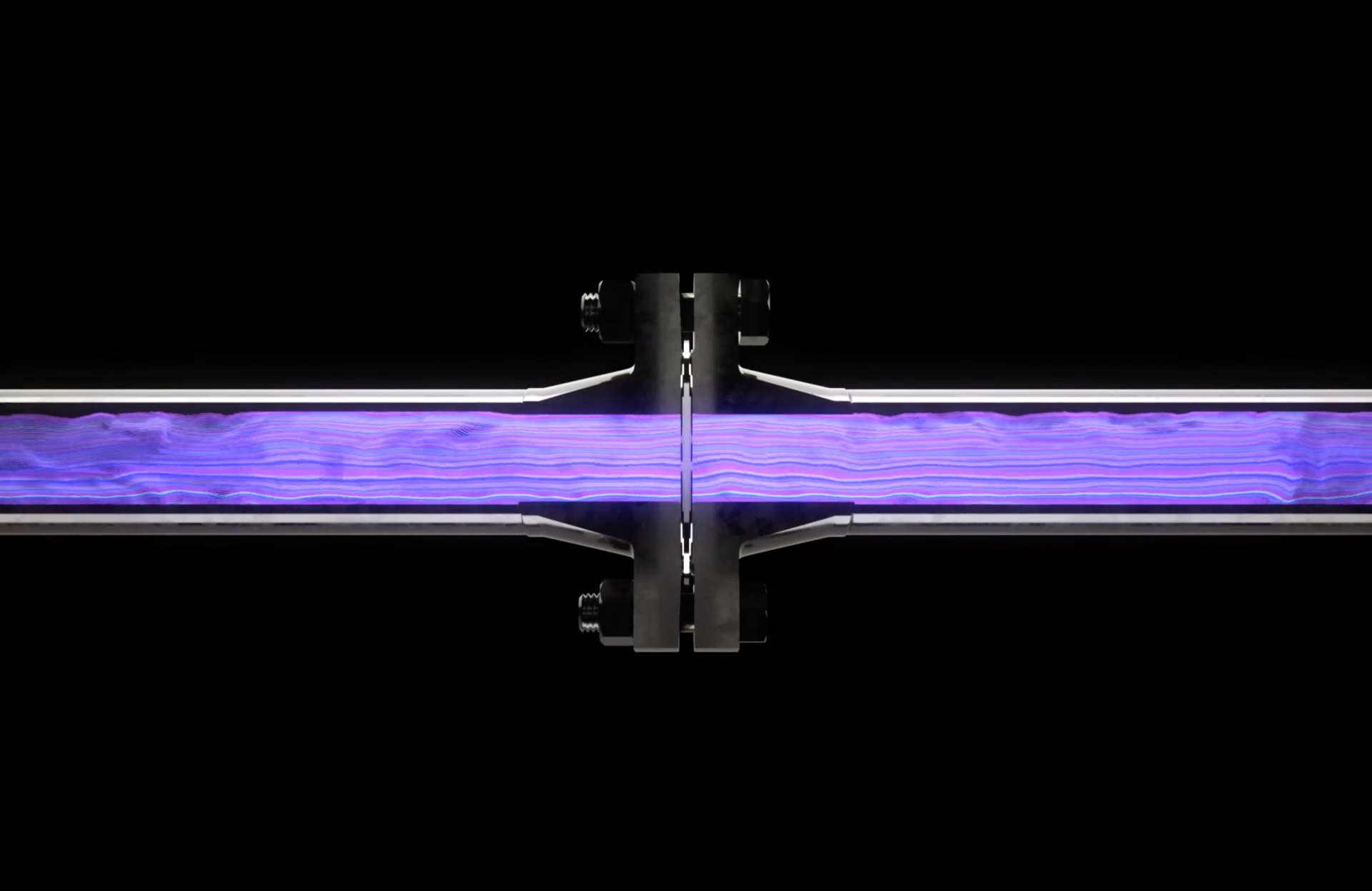

This form of nitric acid synthesis is a cornerstone of any modern fertilizer production facility. However, this process can cause nitrous oxide to leak from the nitric acid lines, and it is 296 times more potent than carbon dioxide.

The customer is a global manufacturer of agricultural fertilizer products with several large facilities in Europe and North America. The customer was experiencing constant flange leakage on their nitric acid lines due to the use of traditional spiral-wound gaskets, leading to regular expensive shutdowns and HSE implications. The customer wanted to eliminate nitrous oxide emissions from the lines to increase safety and reduce environmental effects.

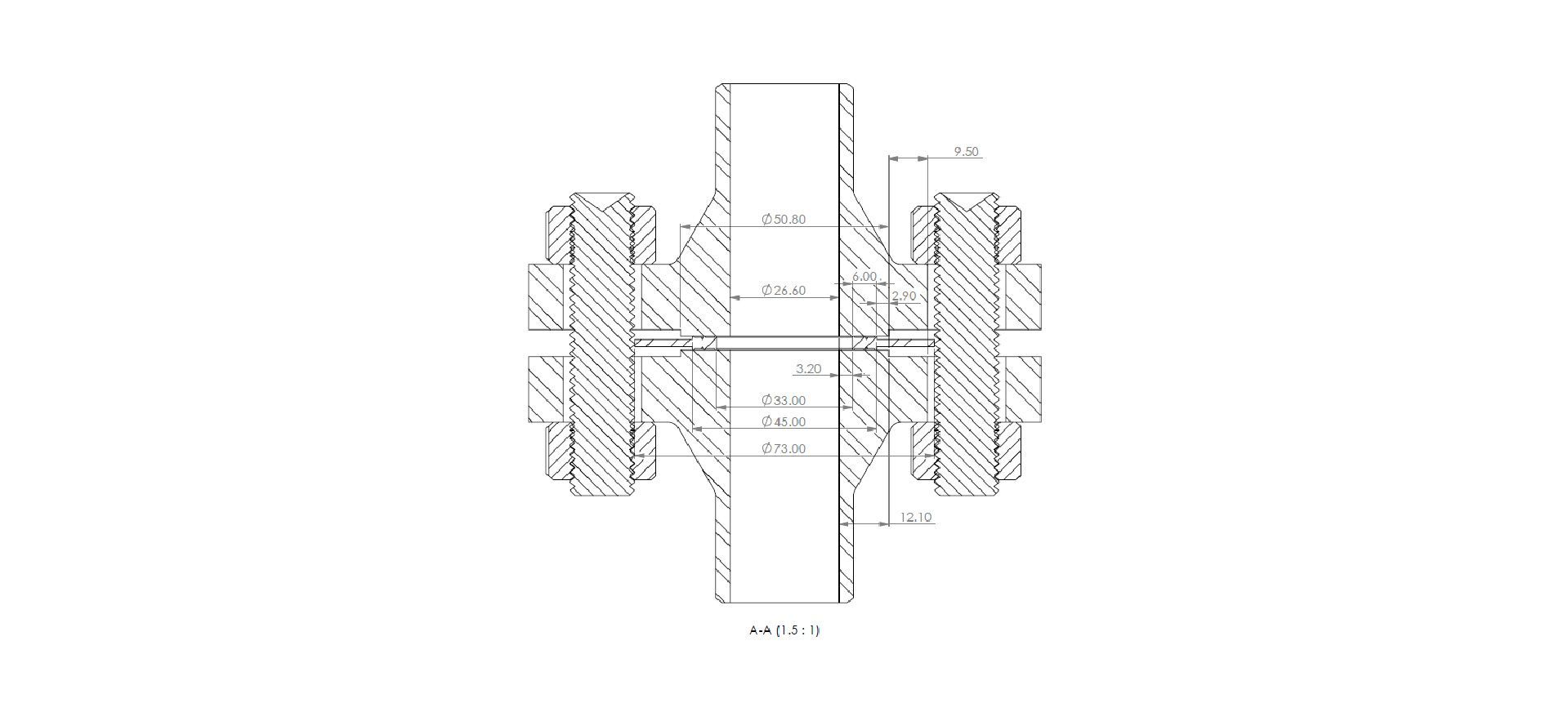

All valves and fittings on the nitric acid lines were stainless steel 316L with the associated piping 304L. Pipeotech put forward the 316L DeltaV-Seal as a long-term sealing solution. The material match ensures corrosion resistance and galvanic compatibility, and the extensive product testing and certification provides the customer confidence that a long-lasting and gas-tight seal can be achieved.

DeltaV-Seal was installed and monitored with zero leakage reported since the initial bolt-up. Installation of DeltaV-Seal provides a gas-tight and maintenance-free sealing solution. In this example, gasket selection has played an important role in creating a safer, more profitable and environmentally sustainable facility.