DeltaV-Seal™ performs under extreme marine conditions

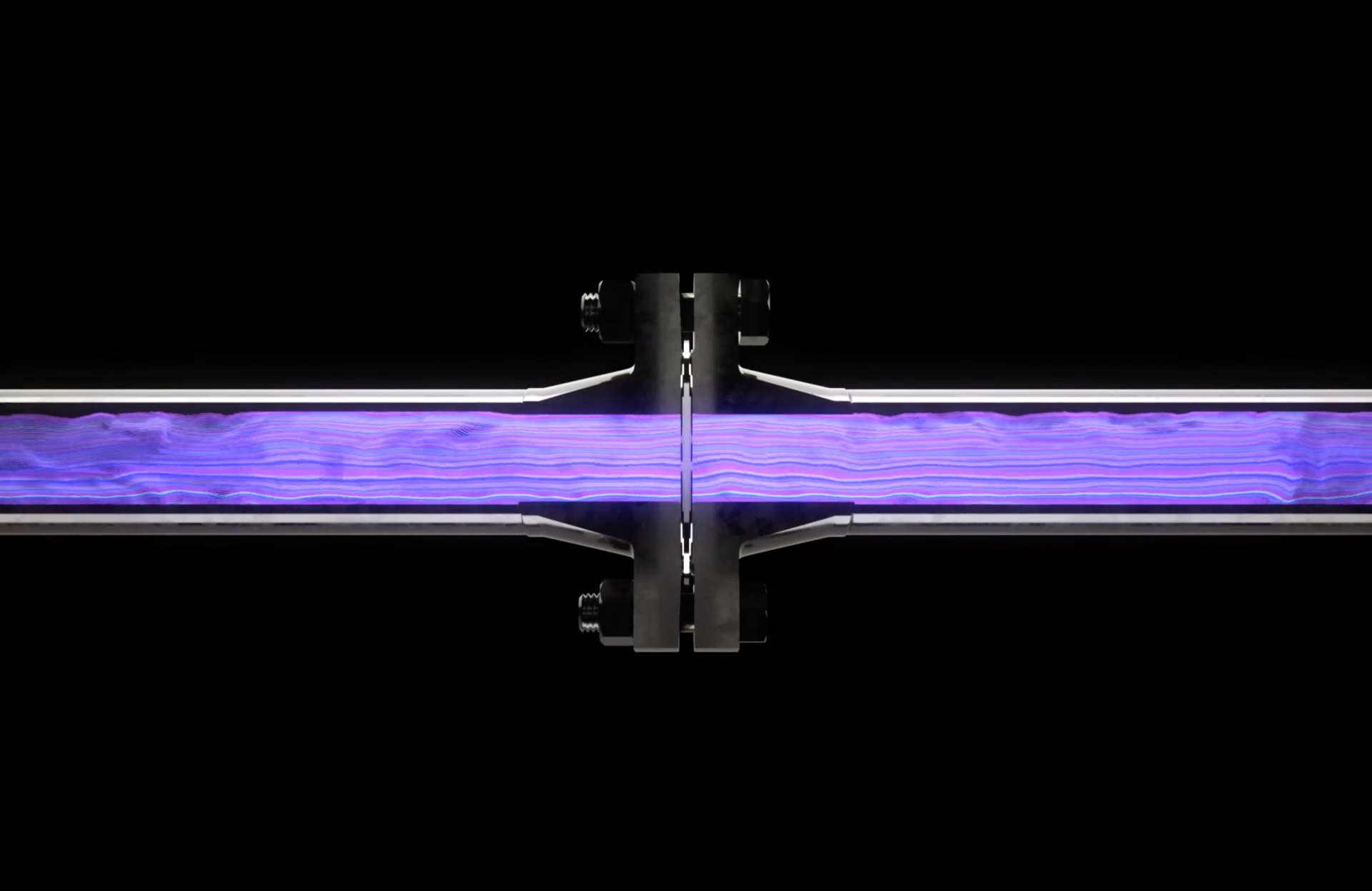

Importing ship-to-shore Liquefied Natural Gas (LNG) requires robust and efficient pipeline seals that are compliant with high environmental standards.

The thermal cycling caused by the cryogenic nature of LNG, as well as the unpredictable marine environment, demands a seal that stays incredibly tight under extreme conditions in order to reduce leakage and to transfer on schedule.

The customer designs and manufactures marine infrastructure solutions for energy distribution. Their pioneering floating LNG transfer system, IQuay™, works by loading, discharging and bunkering LNG without the need for expensive and time-consuming fixed marine infrastructure. This inventive distribution framework calls for a solution not reliant on traditional seals, which leak often and don't perform well under the extreme conditions present in an LNG transfer.

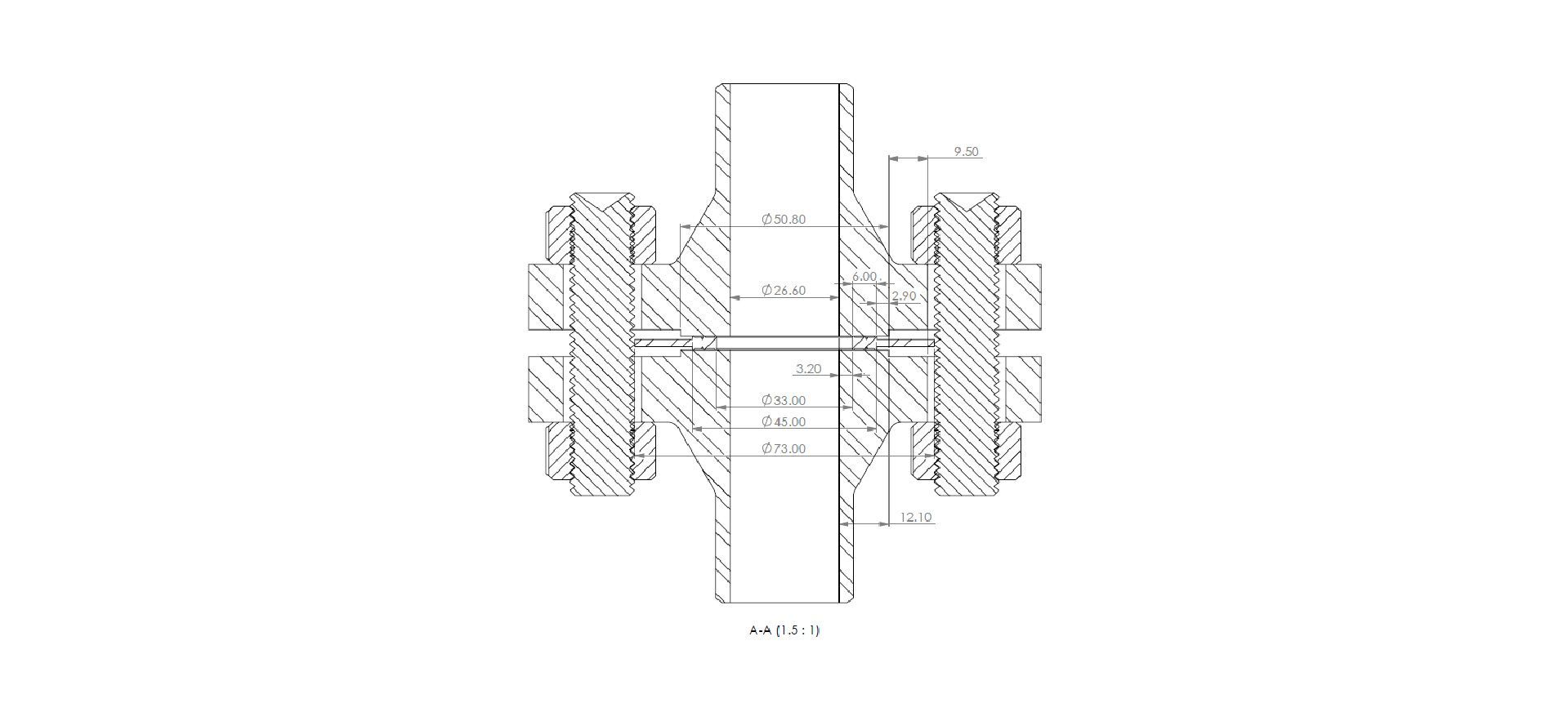

Together with Pipeotech, the customer chose the DeltaV-Seal to work in tandem with its floating LNG system, as the one-piece metal construction and the connecting flange ensures that the seal contracts and expands in seamless unity throughout thermal cycling. Testing has shown that even at -196° C, the DeltaV-Seal has leakage rates 10,000 times less than that of similar gasket solutions.

A smooth, on-schedule transfer of LNG from the vessel-to-shore was achieved with zero leakages, saving time, money and helping the customer further its mission of providing clean, sustainable and climate-positive energy solutions.