The impact of using DeltaV-Seal™ on flange surfaces

Pipeotech has conducted flange surface profile measurements in cooperation with Sintef/DNV to investigate the impact of DeltaV-Seal on flange surfaces in bolted flange joints (BFJ).

Flange surface profile measurements

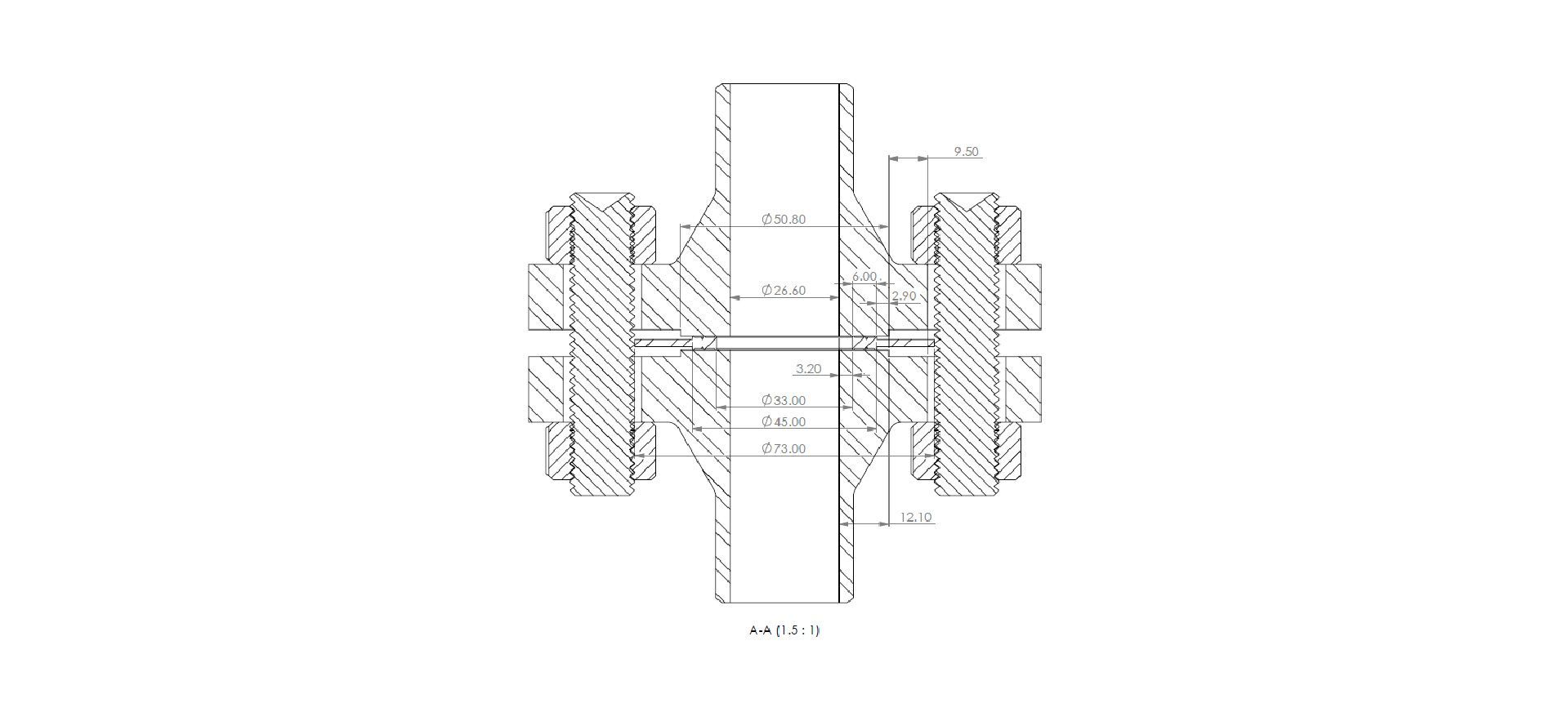

To investigate the impact of 316L DeltaV-Seal on flange surfaces, surface profile measurements were performed after installation of the gasket in 1’’, 6’’ and 12’’ RF flanges, all in #300 and made from 316L. An Alicona Imaging 3D optical-based metrology and imaging system was used for the surface profile measurements and documentation.

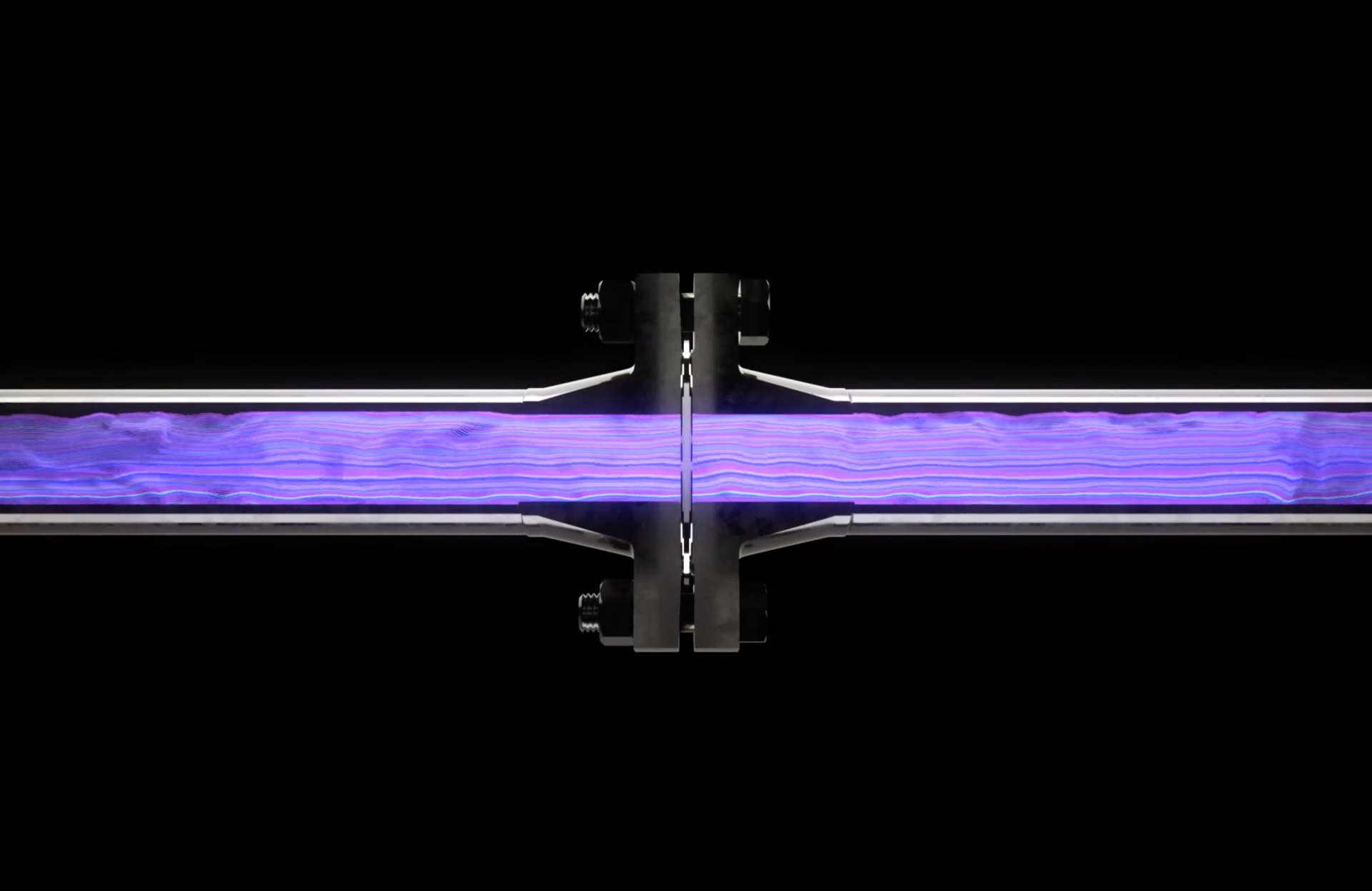

Typical result and documentation presentation from the Alicona Imaging system applied to the tested samples is shown below:

Colour-coded 3D surface profile variation visualization showing concentric flange grooves and three locations of DeltaV-Seal interaction with the flange surface. Purple colour: max. depth 30 μm; Red colour: max. height 25 μm.

Optical image of a 1” flange RF surface with the measurement line in red across with a radial distance of 6 mm between the visible outer and inner ridge interaction locations.

Typical flange surface profile of the tested flanges with the three DeltaV-Seal interaction locations clearly visible in-between the machined grooves with a radial distance of 6 mm between the inner and outer ridge gasket/flange surface interaction locations on the X-axis. Max. height on Y-axis is 20 μm and max. depth on Y-axis is 30 μm. RF width: ≈7.5 mm.