Stopping expensive leakages at historic brewing facility

With the title of ‘the oldest brewery in Norway’, the Aass brewery is about as close as it gets to being a Norwegian institution. Situated on the banks of the river in the busy port city of Drammen in central Norway, this family-run enterprise has been producing a wide range of beers, ciders, spirits and non-alcoholic beverages for the Norwegian domestic market for over 180 years.

Now in its 5th generation of Aass family ownership, the Aass brewery has matured into a highly modern facility, considered to be one of the key players amongst domestic Norwegian Beer producers.

It could be considered simple business acumen to say that to stay in business for as long as Aass have, you have to constantly learn and evolve to meet the needs of your customers. The beverage marketplace is changing constantly requiring innovation and a degree of foresight to remain relevant and profitable.

Aass has met these demands head-on, not only with a diverse and constantly updated product portfolio, but also in the streamlining, modernization and constant review of their brewing processes and technology.

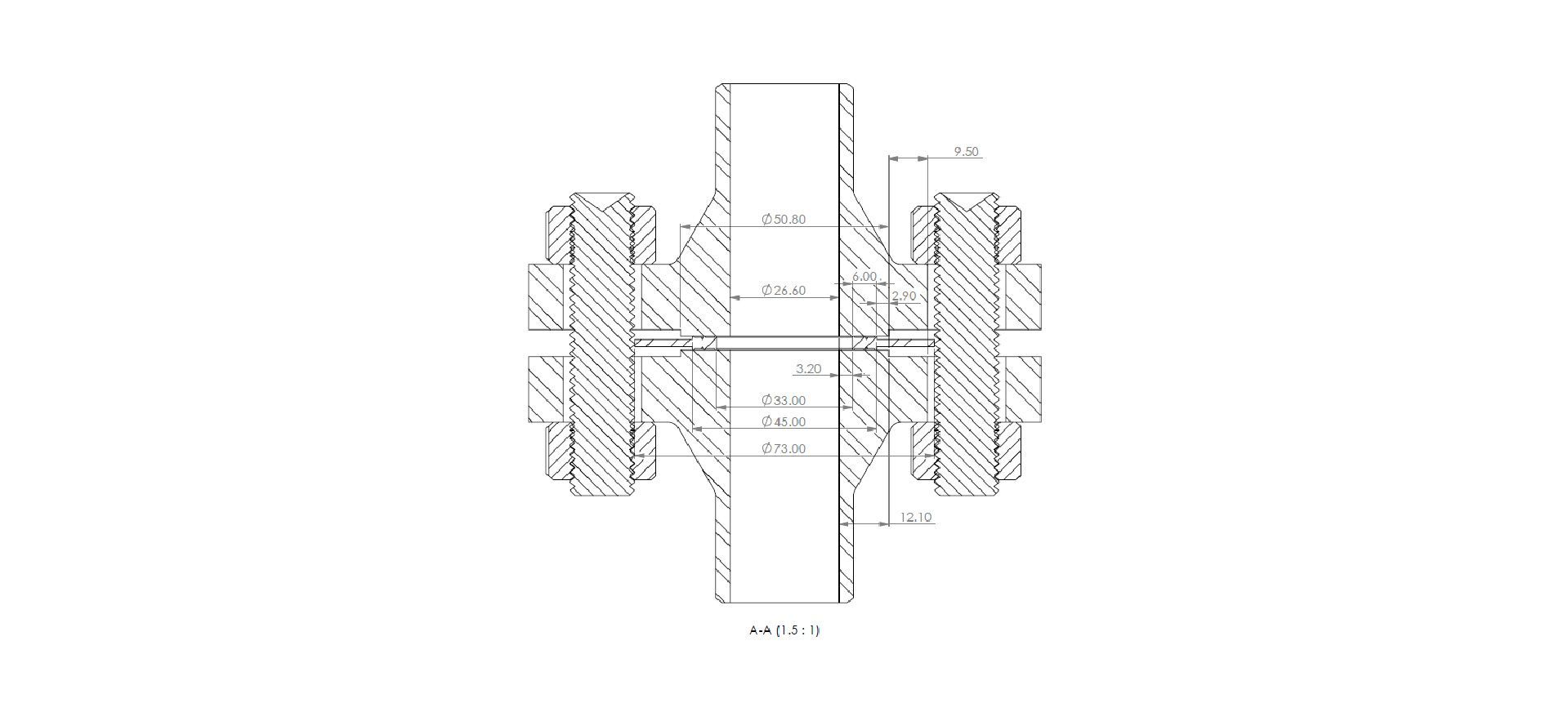

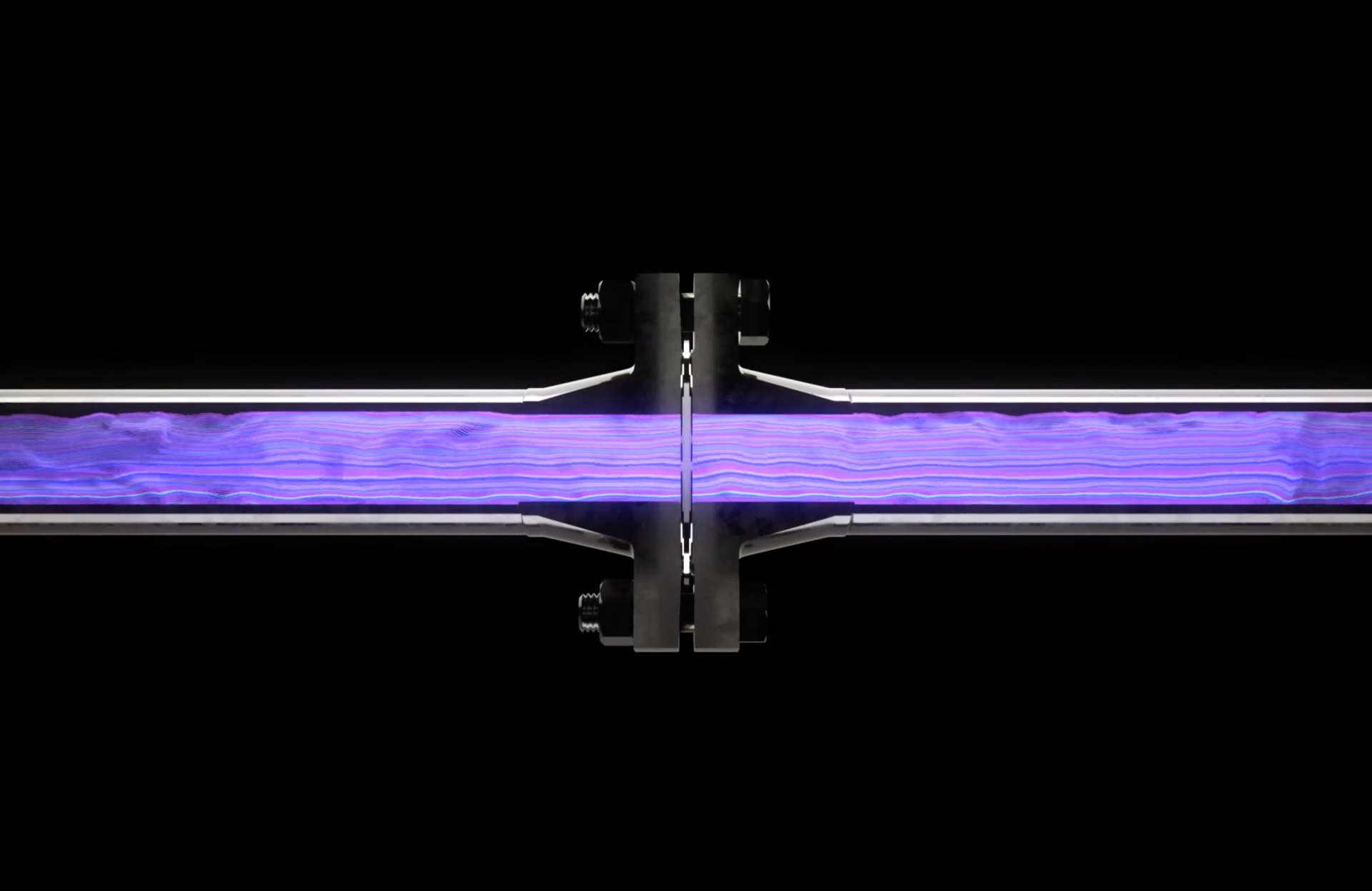

Amongst the numerous vats, tanks, fermenters and filters, pipes, flanges and gaskets are naturally found everywhere throughout the facility, transferring raw fluid ingredients between the different brewing processes. In the past, leakage and contamination prevention presented some real challenges from a piping maintenance point of view.

‘Leakages are expensive’ says Lars Petter Sundve, Maintenance Manager at the Aass Brewery.

‘In the past, we have used Teflon and Metaflex gaskets but have now changed to using DeltaV-Seal™ from Pipeotech due to all of its advantages.’

‘With DeltaV-Seal we save a lot of time when we don't have to include re-tightening the bolts within our maintenance schedule. Also, because the DeltaV-Seal is an entirely metal-to-metal gasket, with no perishable materials, the potential for flange-based contamination is eliminated, and no cleaning of the flanges is required when you do a service.’

– ‘With DeltaV-Seal the potential for flange-based contamination is eliminated, with no cleaning of the flanges required when you do a service.’

Lars Petter Sundve, Maintenance Manager, Aas Brewery

The engineers working at Aass Brewery now prefer to use the DeltaV-Seal due in part to the easy installation process and economic benefits of not having to machine the flange face each time there is a service due to residue build-up. The DeltaV-Seal has now been installed on all old and damaged flanges within the Aass facility where previous gaskets had been leaking and since placing their first order in 2017 there have been no leakages from any DeltaV-Seal.