Semi Conductor application for Nitrogen and Oxygen gas purifiers

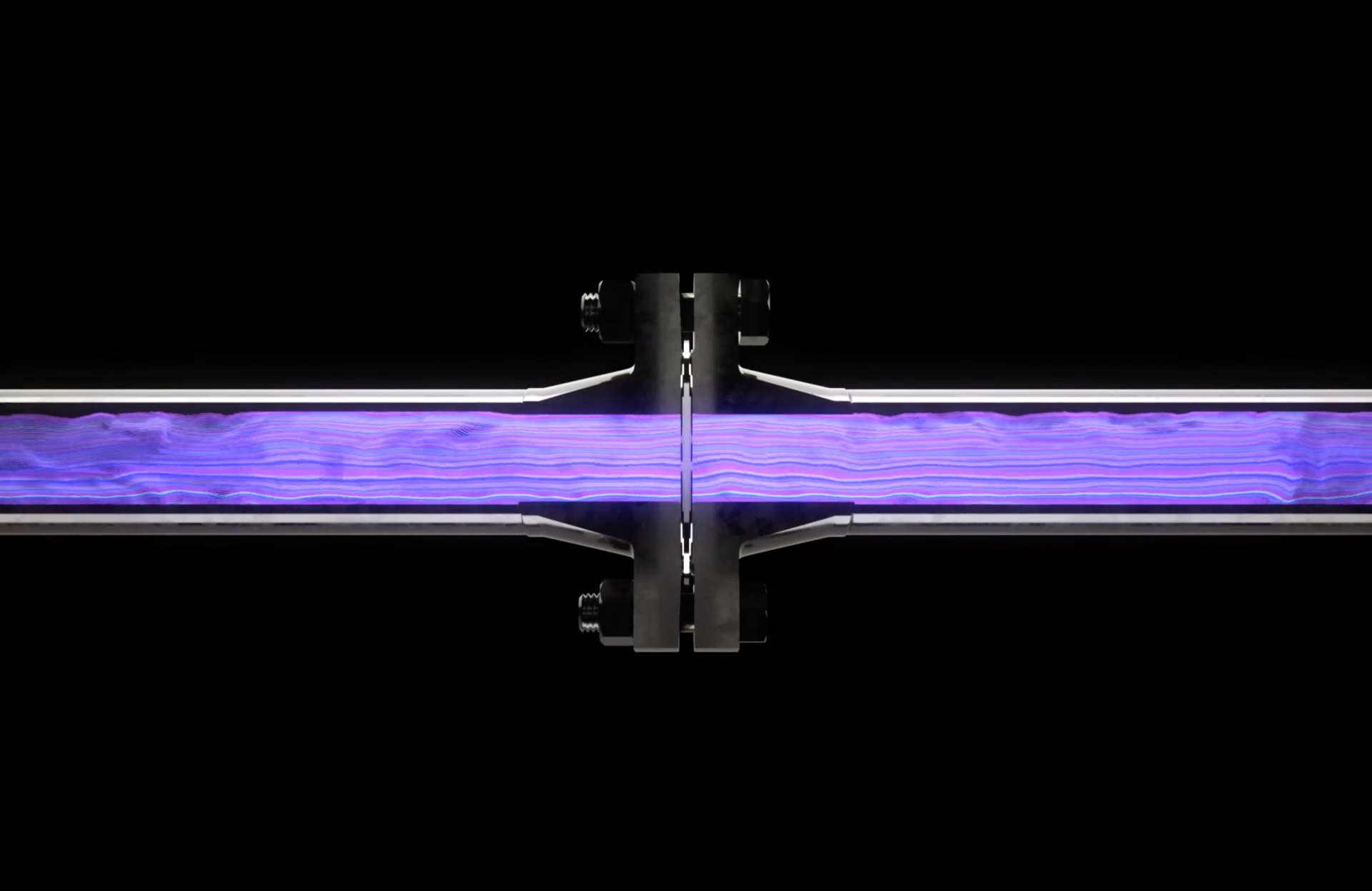

One of the world's leading semiconductor manufacturers in South Korea required a carbon-free, bacteria and virus-tight gasket capable of withstanding temperatures up to 500°C. The DeltaV-Seal™ gaskets are now utilized within many operating systems, including tube-type heat exchangers for Nitrogen & Oxygen gas purification.

Industry Challenges

The Kammprofile gaskets previously utilized could not provide reliable and extended service due to the high temperatures and required frequent shutdowns for replacement. Given the need for extremely high purity levels from the cleaned Oxygen and Nitrogen, the manufacturer also requested low levels of Carbon to be present within the gasket, which is met via the 316L DeltaV-Seal™. A tight and durable gasket was required to perform at high temperatures and provide a bacteria and virus-tight seal.

Background

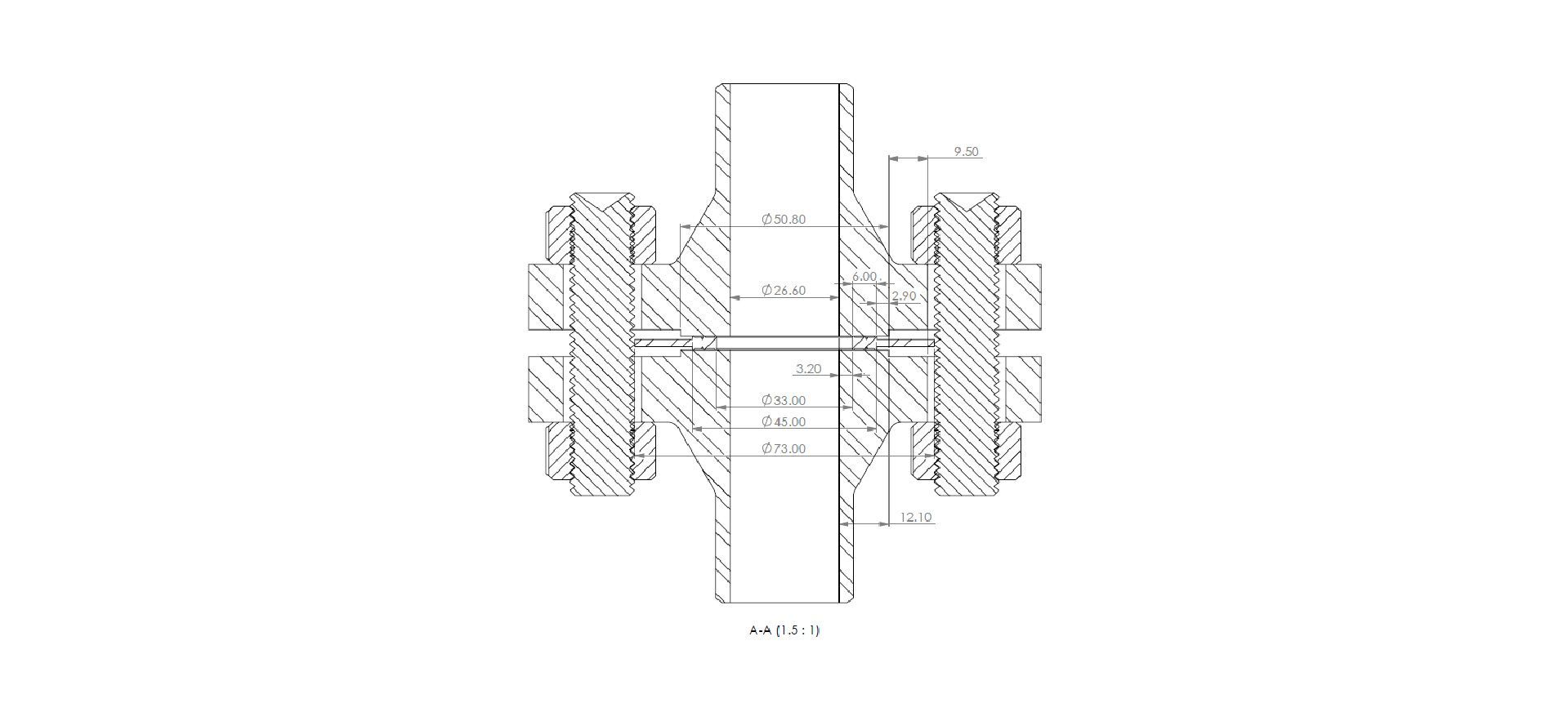

The manufacture of semiconductors requires a clean room environment as the wafers produced are extremely sensitive to environmental containments. One of the world’s leading semiconductor manufacturers contacted Pipeotech looking to improve the performance of bolted flange joints, which are a strategic part of the system purifying Nitrogen and Oxygen. All flanges are raised face per ASME 16.5, and either pressure class #150 or #300 enables off-the-shelf DeltaV-Seal™ gaskets to be utilized required.

Benefits

Due to the leak-free, high-temperature performance, the DeltaV-Seal™ is now part of the best practice guidelines for one of the world’s leading semiconductor manufacturers, allowing higher operating temperatures for increased purity and advances in product performance. With the DeltaV-Seal™ providing an “off the shelf” delivery and simple fix, the semiconductor manufacturer is free to focus on increasing the manufacture of semiconductors to meet the global demand.

Solutions

Pipeotech’s 316L Stainless Steel gasket is the perfect fit. The fully metallic DeltaV-Seal provides a longterm, technically tight and durable high-temperature metal-to-metal seal, with all applications supported with a detailed engineering analysis per EN1591-1. The construction of the DeltaV- Seal™ allows for chemical cleaning as needed and, with zero filler material used, removes all concerns of; mechanical degradation, contamination and relaxation of the gasket.

Download the full case study

Download the case study by clicking the link below: