Pipeotech Q3 Newsletter

Another quarter is in the books here at Pipeotech. Q3 brought many opportunities for the company. Engineers and executives met with clients across the globe and attended various events to share the power of the DeltaV-Seal™.

Asian Sealing Visit Pipeotech

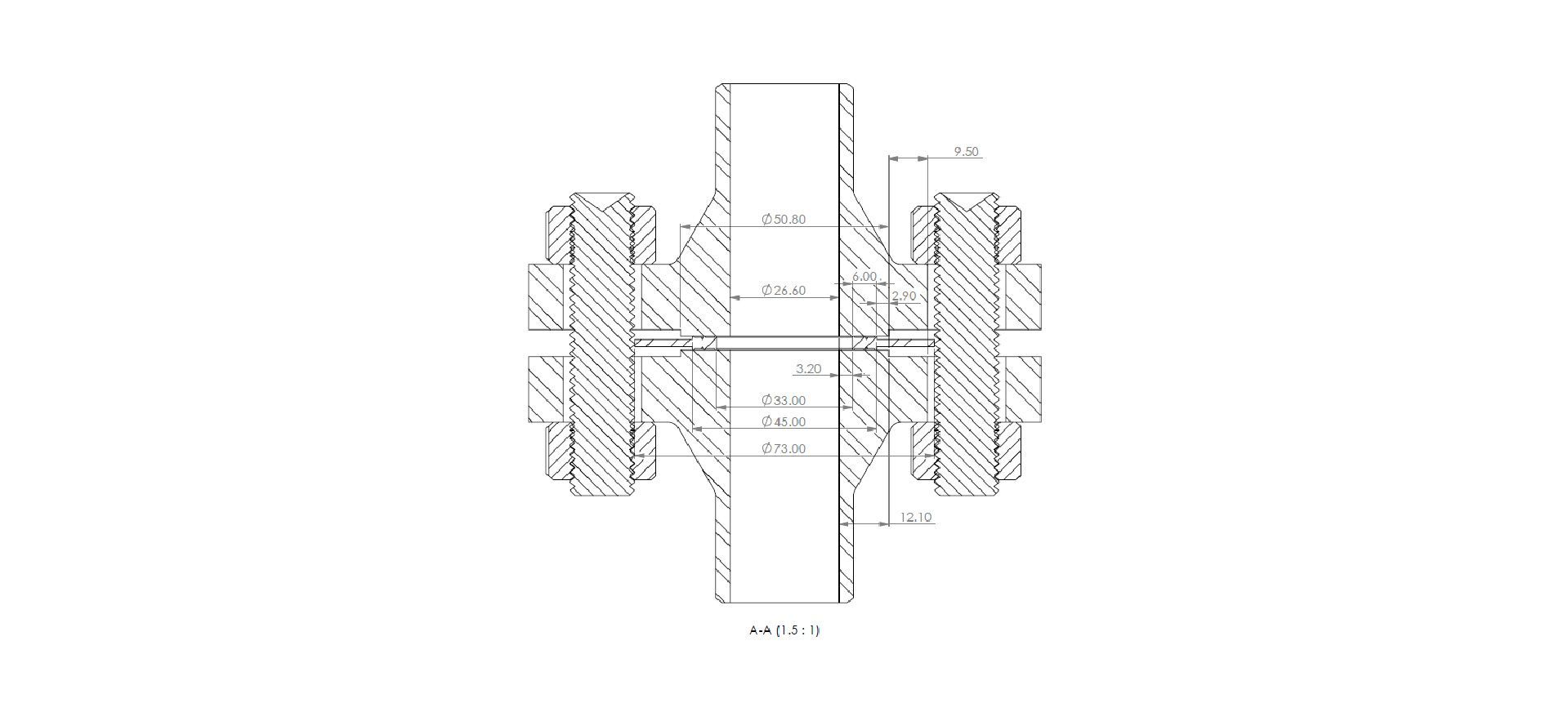

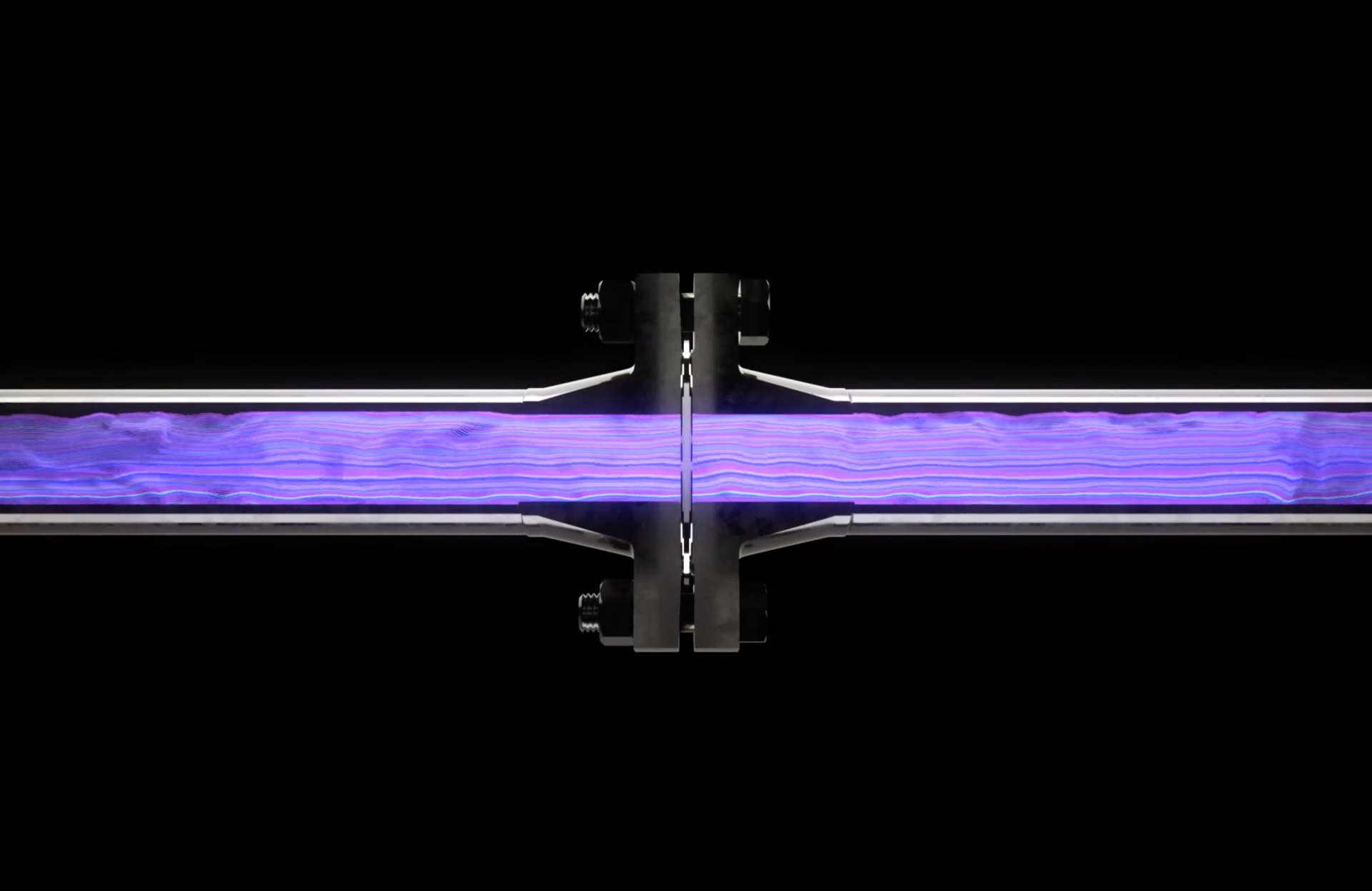

In September, Pipeotech was pleased to welcome and host Mr. Stephen Jang, MD of Korean Sealing Solutions, to their head office in Oslo, Norway. Korean Sealing Solutions uses the DeltaV-Seal™ for challenging sealing applications with the Semi-Conductor industry in South Korea, where high cleanliness and gas-tight sealing performance is needed within service temperatures up to 500°C.

– “It has been a pleasure to work and visit with Pipeotech to understand the detail, flexibility, and value they provide to support the integrity of the complete bolted flange joint and the QA/QC procedures they apply to the manufacture and tolerance of the finished DeltaV-Seal™ product.”

Mr. Stephen Jang, Managing Director, Korea Sealing Solutions

Further Developments

In early October, Jan Oredsson and Andrew Patrick attended the 2022 ANNA conference, where we networked with Ammonium Nitrate and Nitric Acid Producers. Through this event, we showed producers how the DeltaV-Seal™ could keep their plants safe with zero maintenance.

As 2023 quickly approaches, continued use and expansion of the applications for the DeltaV-Seal™ within the semi-conductor and other service-critical applications within South Korea are now expected. Pipeotech was also able to partner with its first stocking distributor in the United States; with this, Pipeotech is hoping to see continued growth in the US market.

With 2022 almost over, we look forward to what the future has in store.