Pipeotech launch new 304L stainless steel DeltaV-Seal for nitric acid service

Working with the chemical industries it is clear Nitric Acid is a particularly challenging chemical to keep within bolted flange joints. Current industry practice on bolted flange joints containing Nitric Acid is to utilize a special blend of PTFE and other chemicals as a gasket.

Discussions between Pipeotech and the industry have highlighted the current industry practice is to regularly replace their current gasket, typically every 6 to 12 months. Every time a legacy semi-metallic gasket is changed the nitric acid system must be emptied and made safe, a significant cost in both time and resources.

– Every time a legacy semi-metallic gasket is changed the nitric acid system must be emptied and made safe, a significant cost in both time and resources.

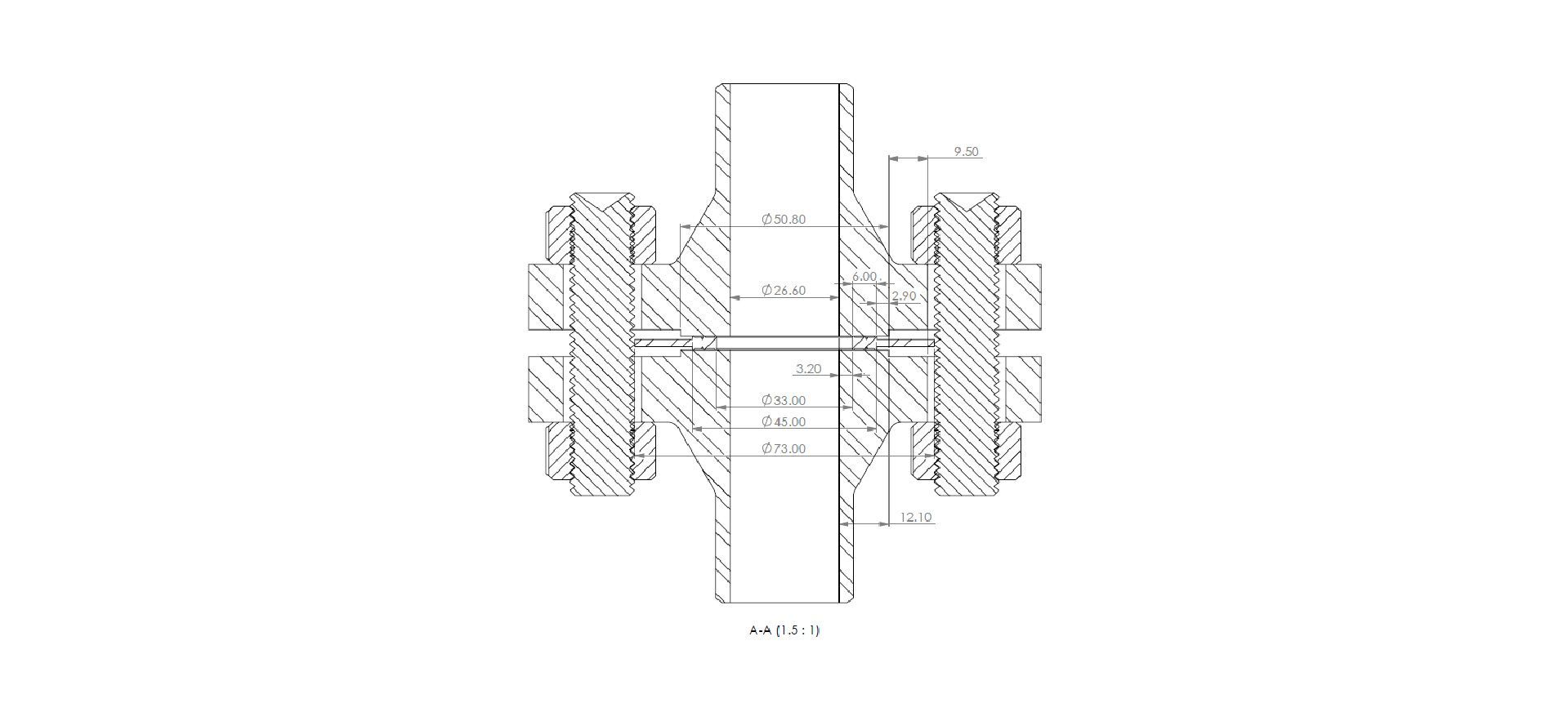

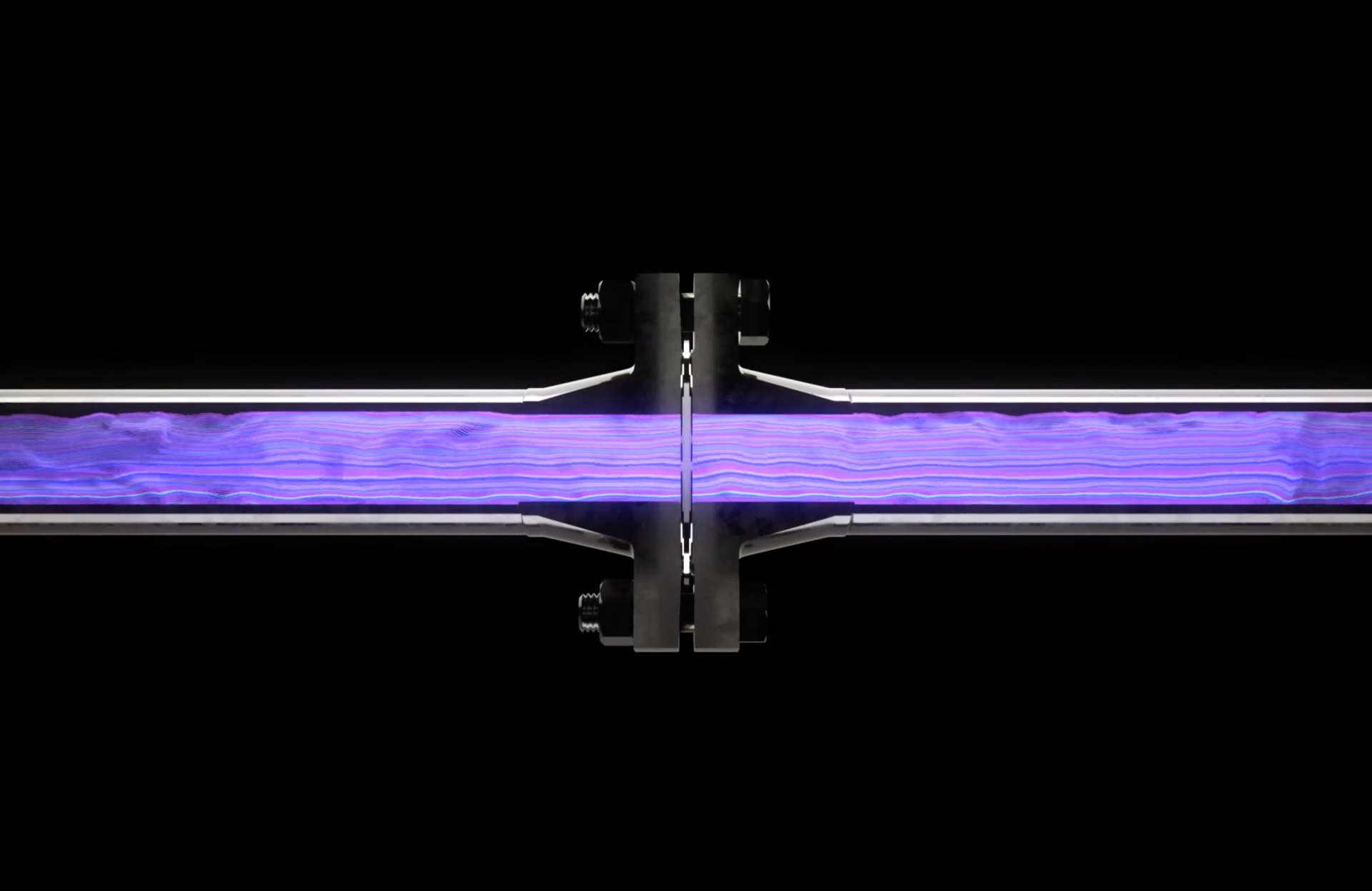

Pipeotech have developed a DeltaV-Seal specifically designed and engineered for Nitric Acid service, normally within fertilizer plants. The new DeltaV-Seal is precision machined from 304L stainless steel to a similar design to Pipeotech’s current gaskets. Due to the versatility of the DeltaV-Seal it allows the one-piece precision CNC machined product to be manufactured in materials compatible to the facilities incumbent pipework system.

As with all Pipeotech’s metallic gaskets, the 304L DeltaV-Seal is designed and engineered specifically to replace legacy spiral wound and Kammprofile gaskets. The fully metallic construction of the DeltaV-Seal is robust and easy to handle, enabling a simple, gas-tight installation that is certain to be maintenance-free for the long term.

Once installed the connection is non-ductile, static, and never requires re-tightening of bolts or fasteners to maintain tightness. All DeltaV-Seal materials have been proven extremely durable particularly to vibration and pressure pulse cycles.

Pipeotech’s new 304L flange gasket has undergone a significant amount of testing, beyond the standard industry requirements within EN13555. The new DeltaV-Seal 304L has been tested up to 40 BarG pressure at temperatures of 20 °C, 200 °C, and 400 °C, to establish its elasticity, relaxation, and leakage rates based on gasket stress. Traditional gaskets only complete these tests at ambient temperatures.

Download the 304L DeltaV-Seal product sheet

– Pipeotech’s 304L DeltaV-Seal will save fertilizer plants millions of dollars by significantly increasing the time between gasket changes. Increasing the time between gasket changes significantly reduces maintenance costs and increases the available uptime of nitric acid units.

Erlend Berntsen, Direct Sales Manager, Pipeotech AS

The new 304L DeltaV-Seal developed in partnership with industry is the perfect gasket for the bolted flange joints of nitric acid piping. Replacing existing gasket technology, the new 304L stainless steel DeltaV-Seal is significantly more resistant to nitric acid than the technology it replaces.

Pipeotech’s 304L DeltaV-Seal will save fertilizer plants millions of dollars by significantly increasing the time between gasket changes. Increasing the time between gasket changes significantly reduces maintenance costs and increases the available uptime of nitric acid units.