Resources

All from News

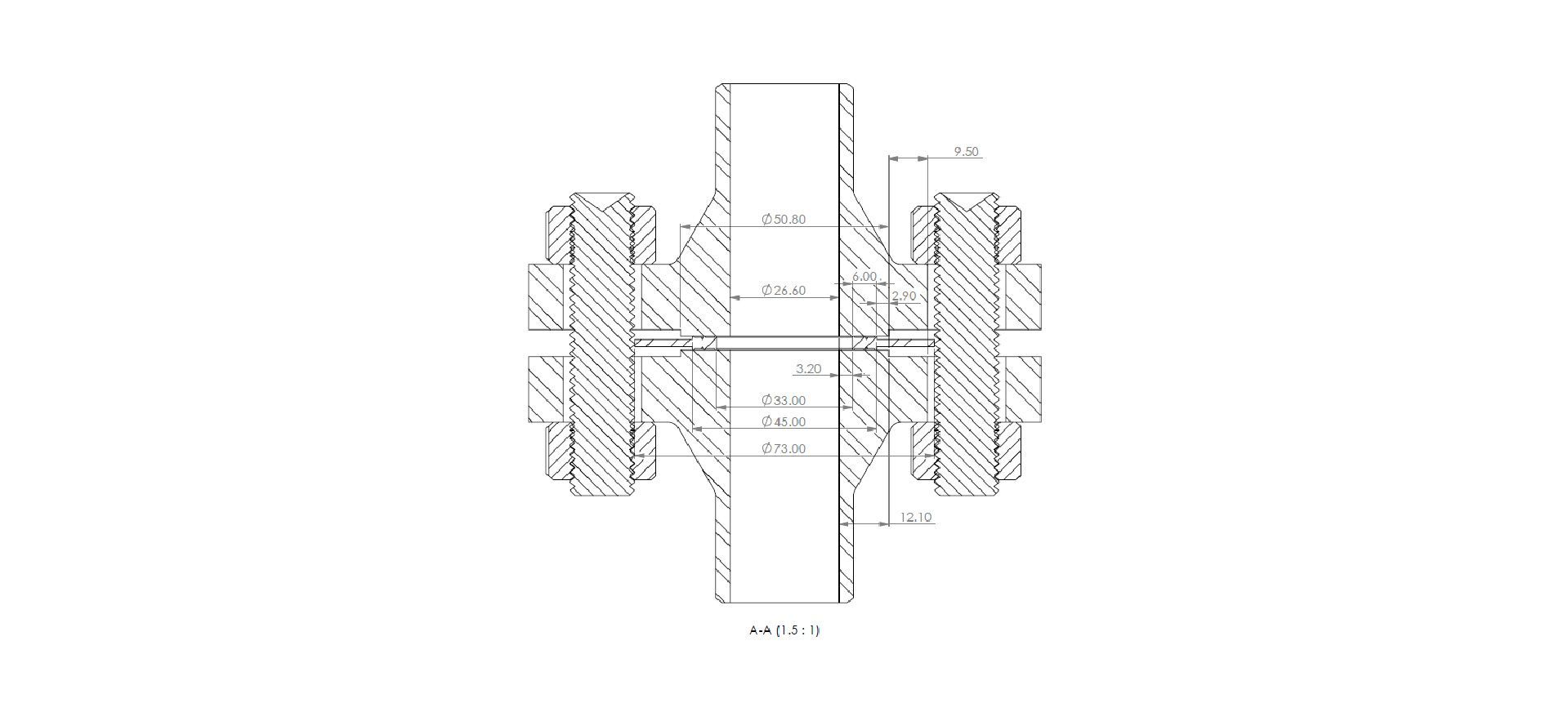

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's Engineering and Technical team have been working to make the modelling and simulation of a gasket a possibility. Being able to simulate the performance of a bolted flange joint, and provide a defined lifetime has huge financial benefit to industry, maximising the time between turnarounds, extracting maximum value from their assets.

Working with the chemical industries it is clear Nitric Acid is a particularly challenging chemical to keep within bolted flange joints. Current industry practice on bolted flange joints containing Nitric Acid is to utilize a special blend of PTFE and other chemicals as a gasket. Discussions between Pipeotech and the industry have highlighted the current industry practice is to regularly replace their current gasket, typically every 6 to 12 months. Every time a legacy semi-metallic gasket is changed the nitric acid system must be emptied and made safe, a significant cost in both time and resources.

On the 13 January 2023, The Netherlands, Germany, Denmark, Sweden and Norway took the first formal step towards a European ban on polyfluoroalkyl substances (PFAS) by jointly submitting a restriction proposal to the European Chemicals Agency (ECHA). PTFE, (polytetrafluoroethylene), belongs to a subgroup of PFAS called fluorinated polymers.

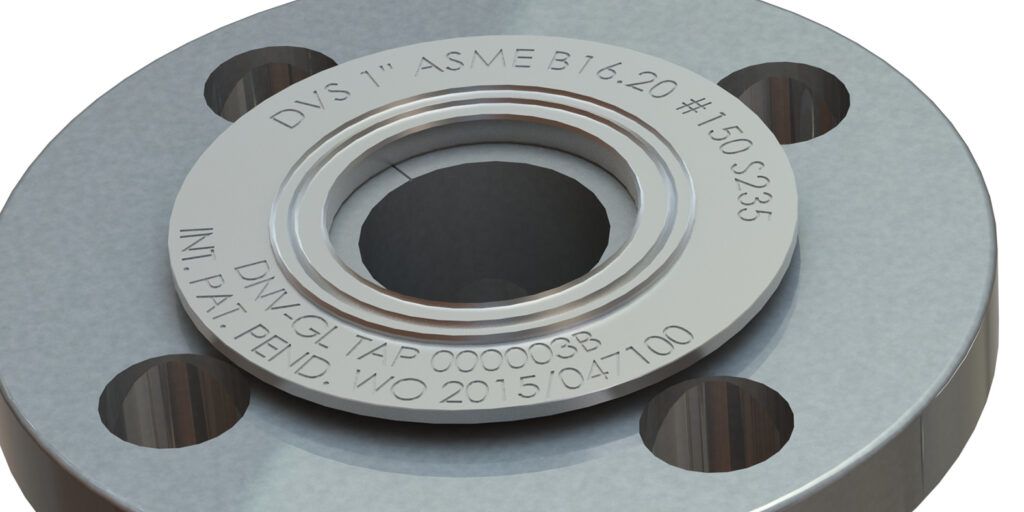

Pipeotech's project with a global manufacturer of peroxide has been featured within Fluid Handling Pro. The article details the design considerations for a gasket utilized in an extremely pure peroxide production unit, along with the specialist cleaning required to prevent contamination and ensure safety.

In July 2021, one of the sealing industry's most widely circulated publications, Valve World, featured Pipeotech CTO Jan Oredsson inspecting a DeltaV-Seal gasket on its front cover, hailing Pipeotech as trailblazers within the zero leakage gasket space. This momentous occasion was augmented by a feature article penned by editor Lucien Joppen explaining how DeltaV-Seal gaskets can help companies with their triple bottom line.