Fortum Oslo Varme chooses zero-emission gasket

Fortum Oslo Varme continued carrying out efforts to phase-out the remaining fossil fuel burning operations in favor of biofuel solutions from oil burning facilities located in Haraldrud, Vika, and Ullevål. With its primary objective to reduce the risk of leaks, environmental contamination, and maintenance costs, Fortum Oslo Varme announced its decision to utilize Pipeotech's next-gen DeltaV-Seal sealing solutions in these three locations. To-date the company is happy to report a very positive experience with the performance of DeltaV-Seals.

Numerous large district heating suppliers have begun following suite in undergoing the process of upgrading their current reserve storage facilities. Under normal operations energy suppliers extract their main source of energy production from waste incineration or other forms of Eco-friendly fuels. However, it is during the coldest hours or in emergency scenarios that the demand for more heat forces suppliers to utilize their (fossil-fuel based) reservoirs and peak load installations. Having recognized the need for new Eco-friendly solutions, these reserve systems have begun being upgraded for use with bio-fuels.

– Fortum Oslo Varme is currently using non-fossil fuels in a normal situation, but in those hours when power and energy needs are greatest, we must make sure that reserve and peak feeding systems start," said Anders Norling, Director of Technical Development, Fortum Oslo Varme. "Measures and improvements that can strengthen delivery safety and reduce maintenance costs are always interesting.

Tasked with overseeing the design of the new facilities was Department Manager Hallstein Brandal of Norsk Energi AS. He explained that the DeltaV-Seal was selected as the sealing solution because of its ability to withstand temperature fluctuation. His previous experience with traditional seals shows leaks occur when fluids in a piping network are exposed to temperature fluctuations.

– This requires re-tightening and maintenance, which quickly becomes expensive at large plants like this one

Hallstein Brandal, Department Manager, Norsk Energi AS

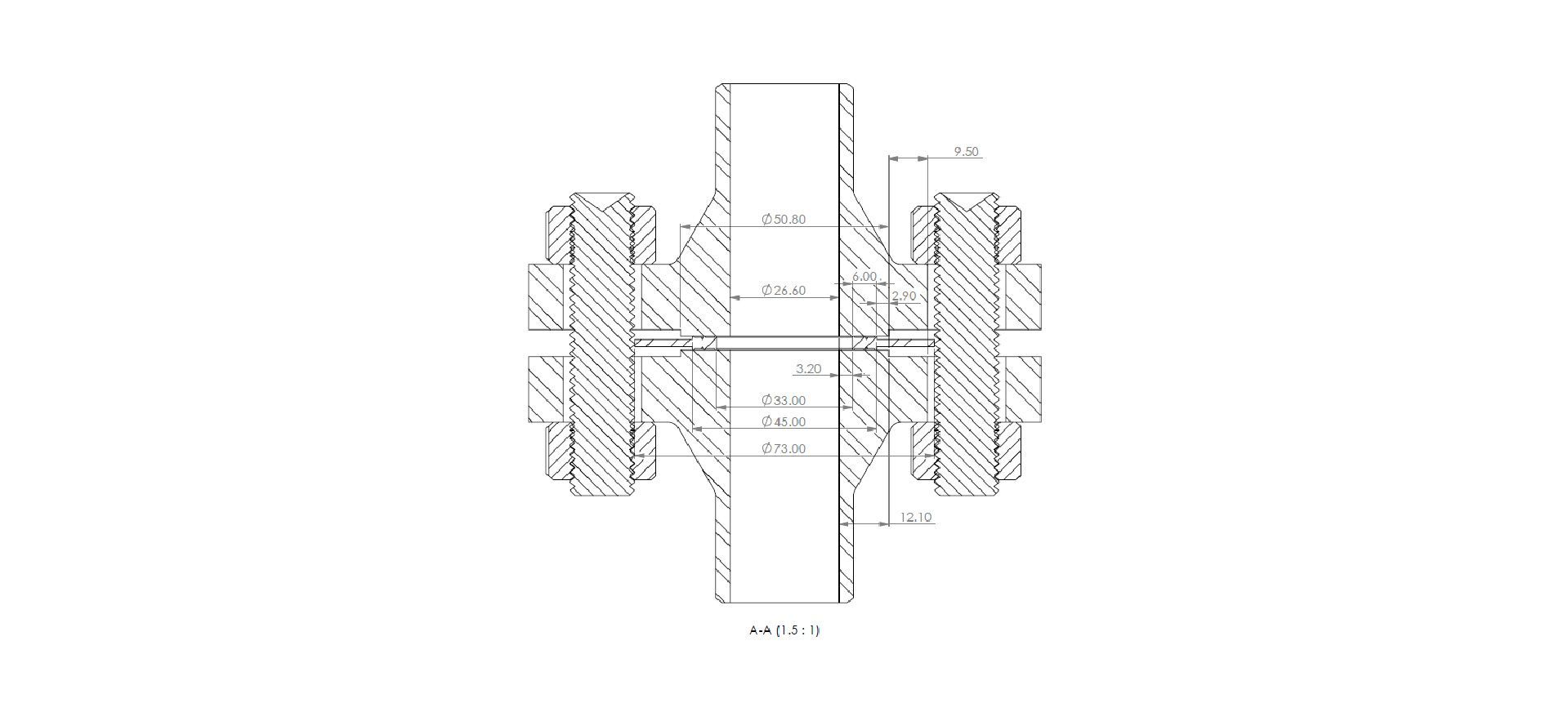

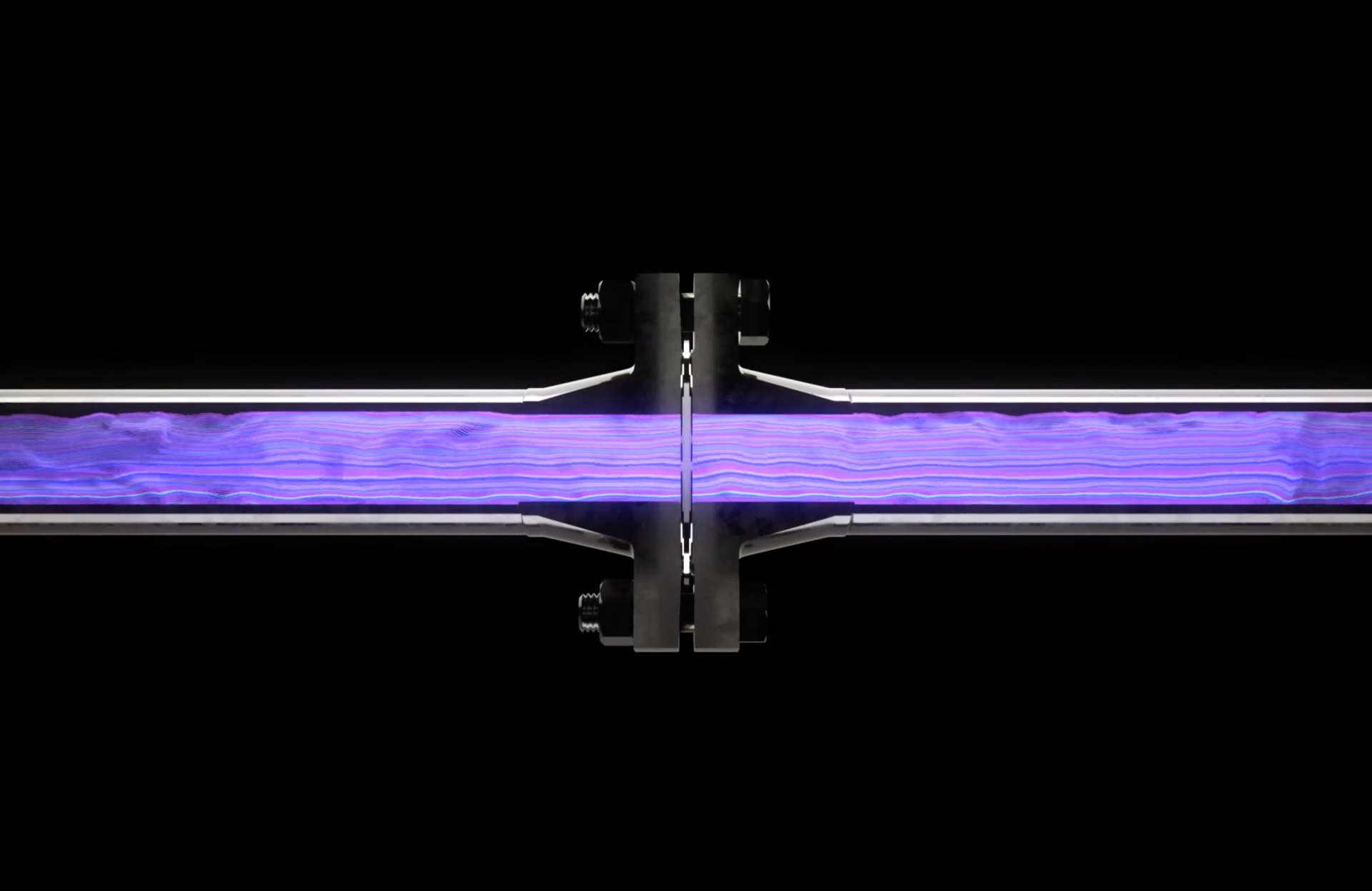

DeltaV-Seal's patented metal-to-metal sealing technology has a valuable advantage since the re-torquing of flange bolts is never required due to fluctuations in temperature. The metal seal expands and contracts in unison with the pipe flange regardless of temperature fluctuation.

– Pipeotech's sealing solution is not significantly more expensive than other products, so we were interested in testing it. So far, it looks promising, and we have hope that this solution will stand the test of time

Hallstein Brandal, Department Manager, Norsk Energi AS

Having carried out the installation process, Enwa PMI AS also gave Pipeotech's new sealing technology high praise. Enwa PMI AS's Project Manager, Morten S. Helgesen, emphasized the team's complete satisfaction with the DeltaV-Seal carbon steel product, as well as the level of Pipeotech's customer service.

– The seals were delivered at the agreed price and were in our hands the day after ordering - sometimes the same day. The flange seals were installed, and the bolts were tightened according to Pipeotech's torque tightening table. Since that time, Fortum Oslo Heating has not had a single leak in the flanges after the plant was put into service three months ago, and there has been no need to re-tighten flange bolts.

Morten S. Helgesen Projector Manager, Enwa PMI AS