Flare tip leakage is too hot to handle for the competition

Pipeotech was called upon to provide a solution for Flare Tip flange leak in the North Sea.

A North Sea Operator came to Pipeotech with a problem affecting a Flare line on their platform. This was due to the dynamic operating conditions caused by a phenomenon called internal burning.

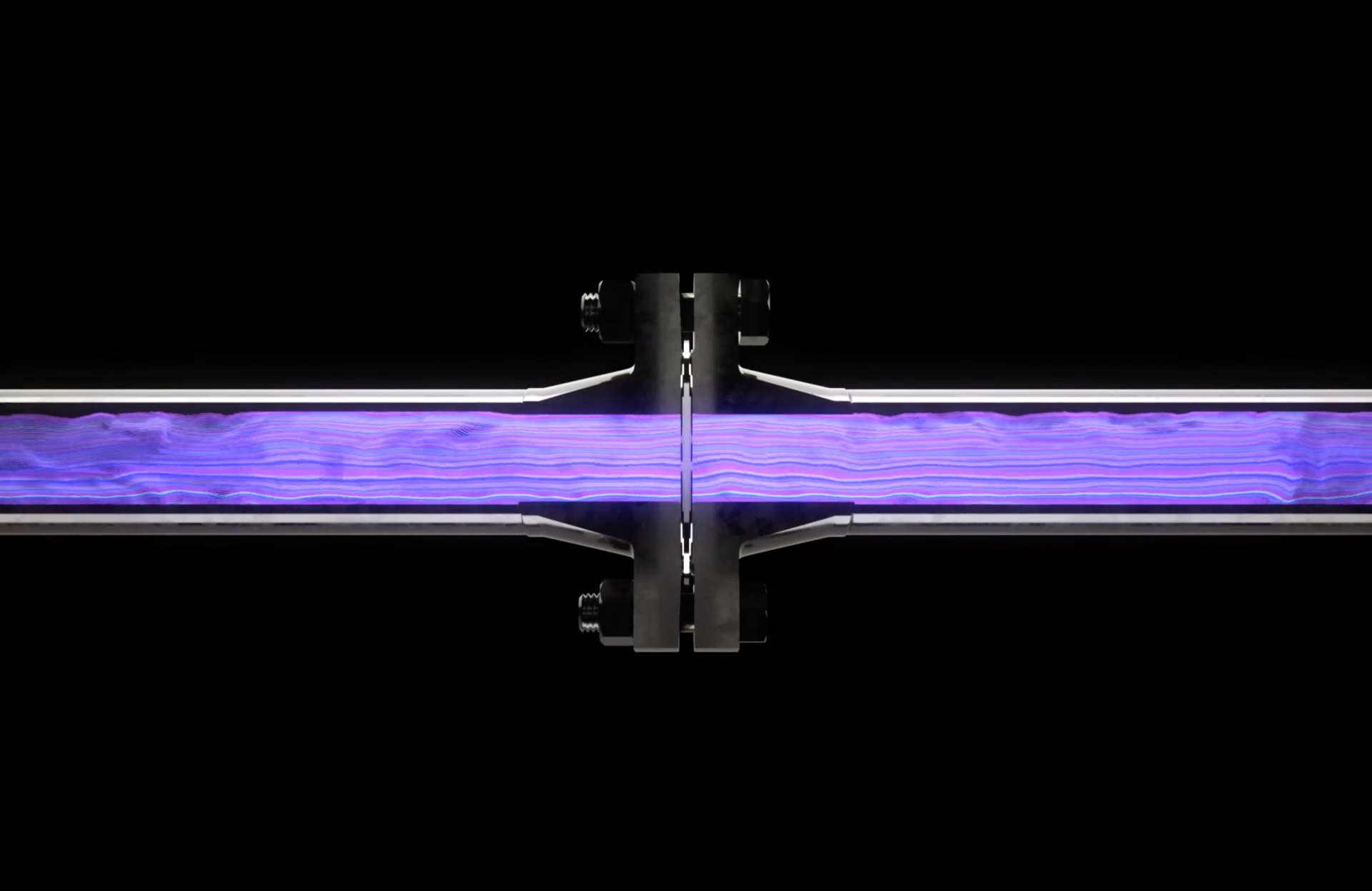

This occurs when the internal flare line stabilizes inside the flare tip, at temperatures around 400c, and cannot be driven out without a substantial increase in flaring rates. During blowdown the tip is quenched down to -50c and this rapid change in temperature provides a huge challenge for any traditional gasket to seal for a long period of time.

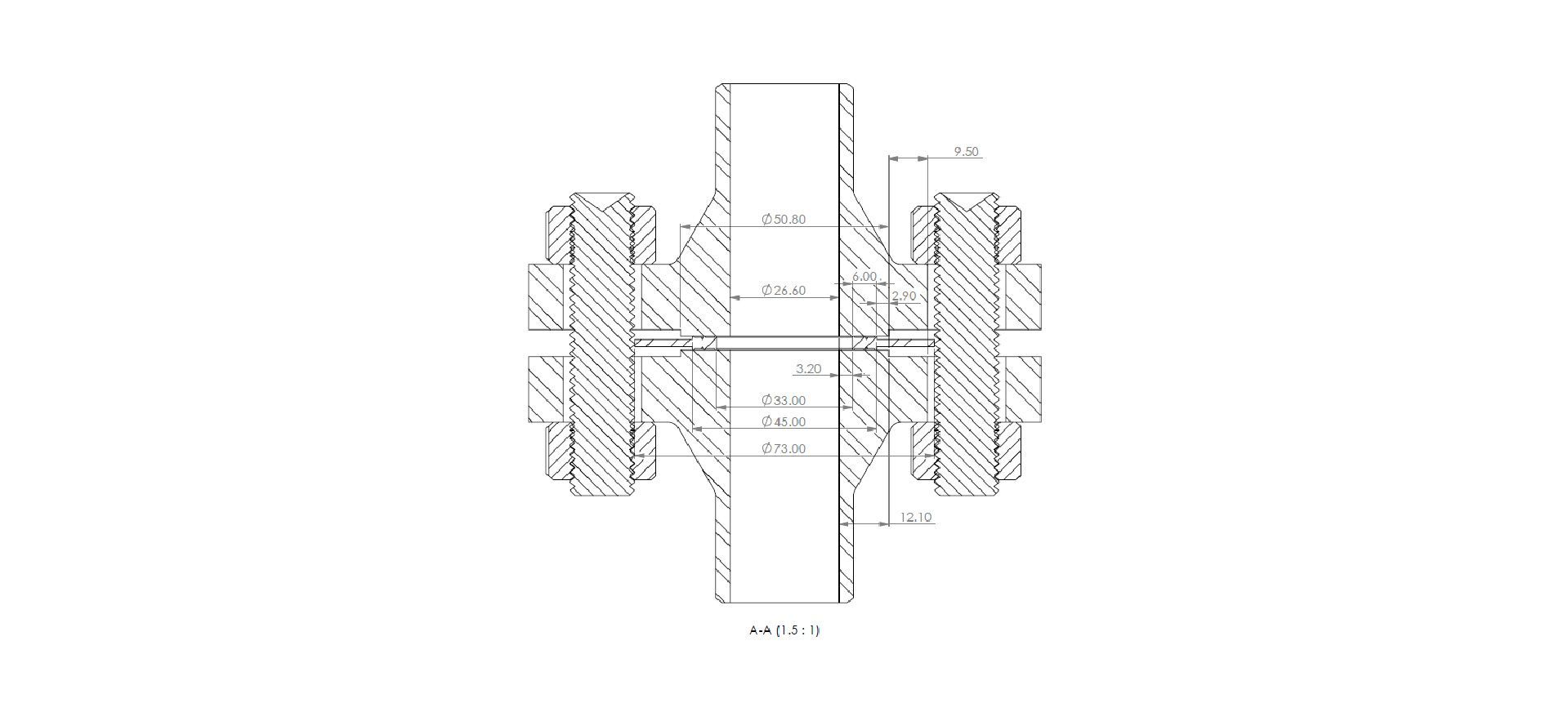

Pipeotech were asked if they had any alternatives that could be offered to cope with the dynamic operating conditions and they were only too pleased to look at this challenging application. The product offered as the solution was the DeltaV-Seal™. This gasket solution is a revolutionary new design offering clients an all in one, metal-to-metal seal that can be used in raised faced, as well as flat-faced flanges.

The DeltaV-Seal is precisely engineered and machined with a triple ring configuration that conforms to the flange face. These provide an extremely tight and reliable metal to metal seal even at very high temperatures.

Since the gasket is all metal (manufactured from the same material as the flange), the gasket contracts and expands at the same rate as the flange material during thermal fluctuations, providing a tighter seal than other gaskets. These benefits led the operator to purchase the 20" 150lb Delta-V Seal gaskets and installed them in July 2018.

5-years on

In 2023 Pipeotech contacted the operator, who confirmed the gasket remains in place with absolutely no issues to date. The operator is now looking for other locations where traditional gaskets requrie regular replacement and the DeltaV-Seal can provide significant maintenance savings.