DeltaV-Seal™ prevent fires, promote safe environment

The use of hot oil systems in manufacturing presents challenges when traditional gaskets breakdown and cause leakage. As liquids in the system are kept at a temperature above their flash point, when they escape they can cause fires and even explosions in the facility.

The customer is a leading international manufacturer and supplier of paints and powder coatings with a total of 39 production facilities and approximately 10,000 employees worldwide. They have a presence in over 100 countries and supply paints and coatings specially developed for the residential, shipping and industrial markets.

The customer was experiencing regular gasket leakage in its hot oil systems, and as the company is invested in Health, Safety and Environment (HSE), this needed to be addressed to prevent facility fires, to increase efficiency and to ensure the safety of its employees.

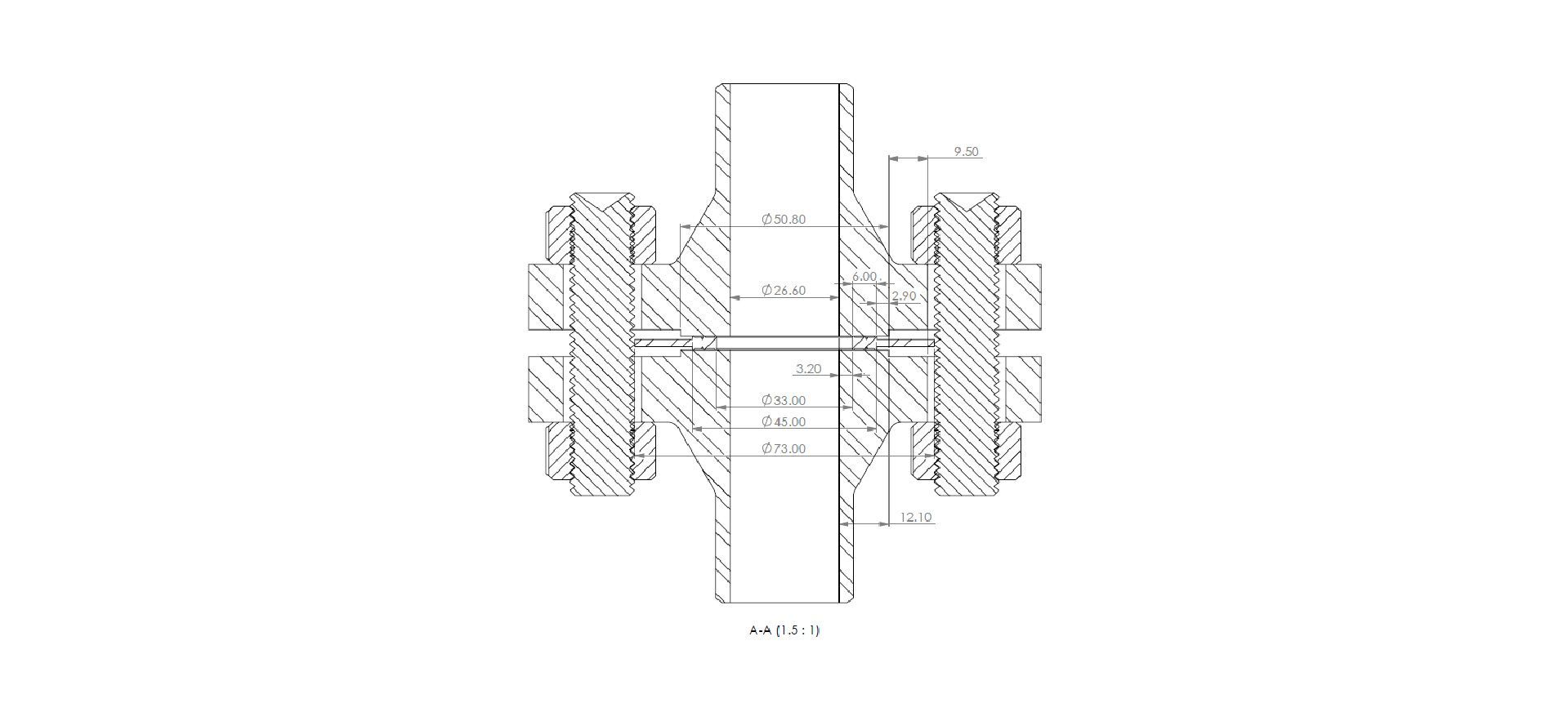

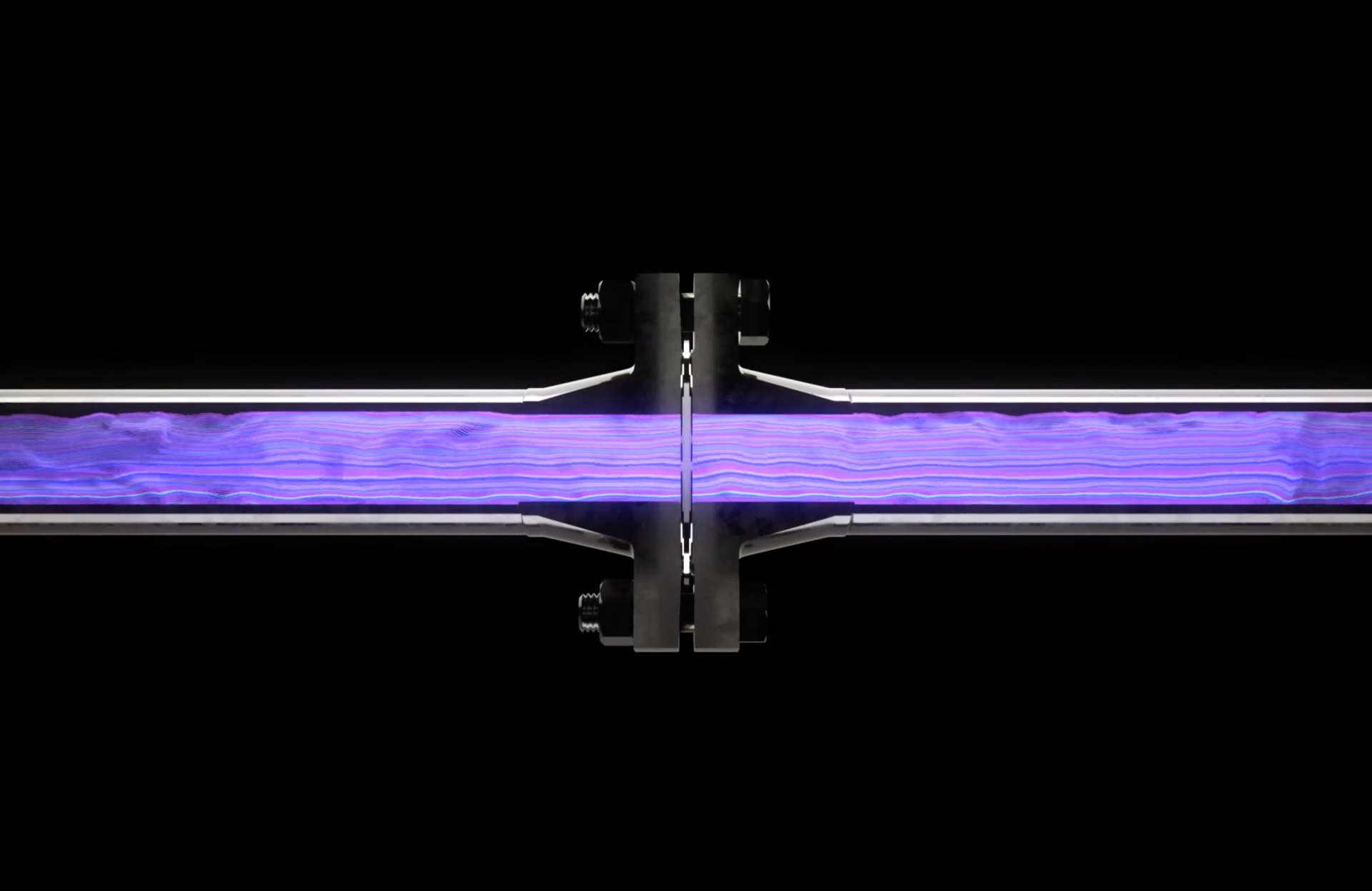

Pipeotech proposed the DeltaV-Seal as an effective alternative to leaky traditional seals. The one-piece metal is machined in a compatible material to the connecting flanges, which completely mitigates seal failure due to temperature fluctuations. Not only does the seal achieve a phenomenal tightness at time of installation, the flange and seal expand and contract in unison providing a seamless and static connection that stays tight over time, regardless of the temperature.

The customer has had no leakages on their hot oil system since installation, which not only increases efficiency and reduces maintenance costs and downtime, but also provides a safer environment for its employees.