Corporate environmental responsibility ‘done right’ with long-term methane mitigation by design

Methane is one of the most potent greenhouse gases and avoiding leakage is a priority when using methane systems. Methane also ignites easily, so there are clear and immediate HSE incentives for maintaining absolute process integrity.

Traditional pipeline gaskets often leak and need frequent maintenance, which must be considered when choosing seals for a methane system.

Methane is one of the most potent greenhouse gases and avoiding leakage is a priority when using methane systems. Methane also ignites easily, so there are clear and immediate HSE incentives for maintaining absolute process integrity. Traditional pipeline gaskets often leak and need frequent maintenance, which must be considered when choosing seals for a methane system.

The customer is a large multi-national pharmaceutical corporation that has owned and oper-ated a manufacturing plant in southern Norway for almost 40 years. This facility is one of the major suppliers in the world for medical contrast media and has many miles of piping with thousands of valves and flanged connections.

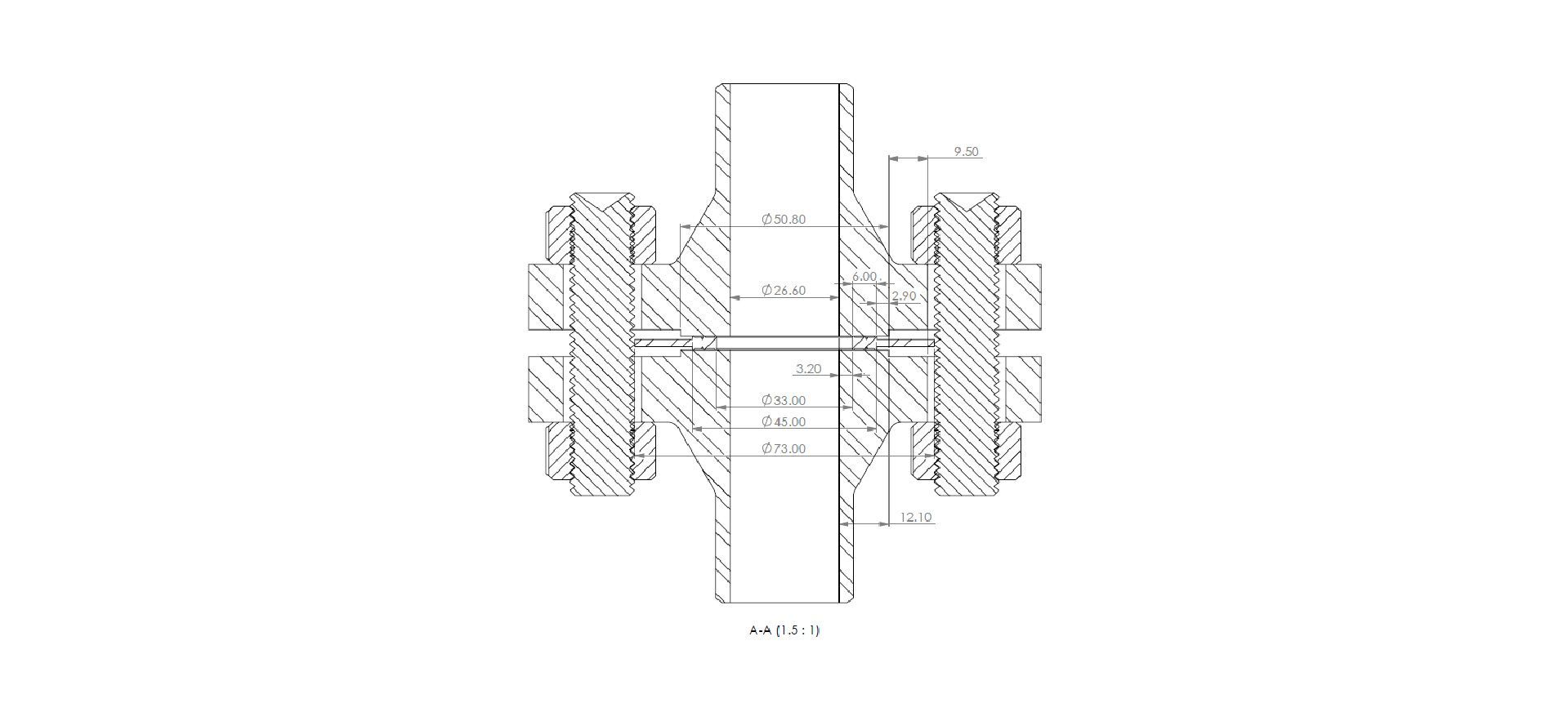

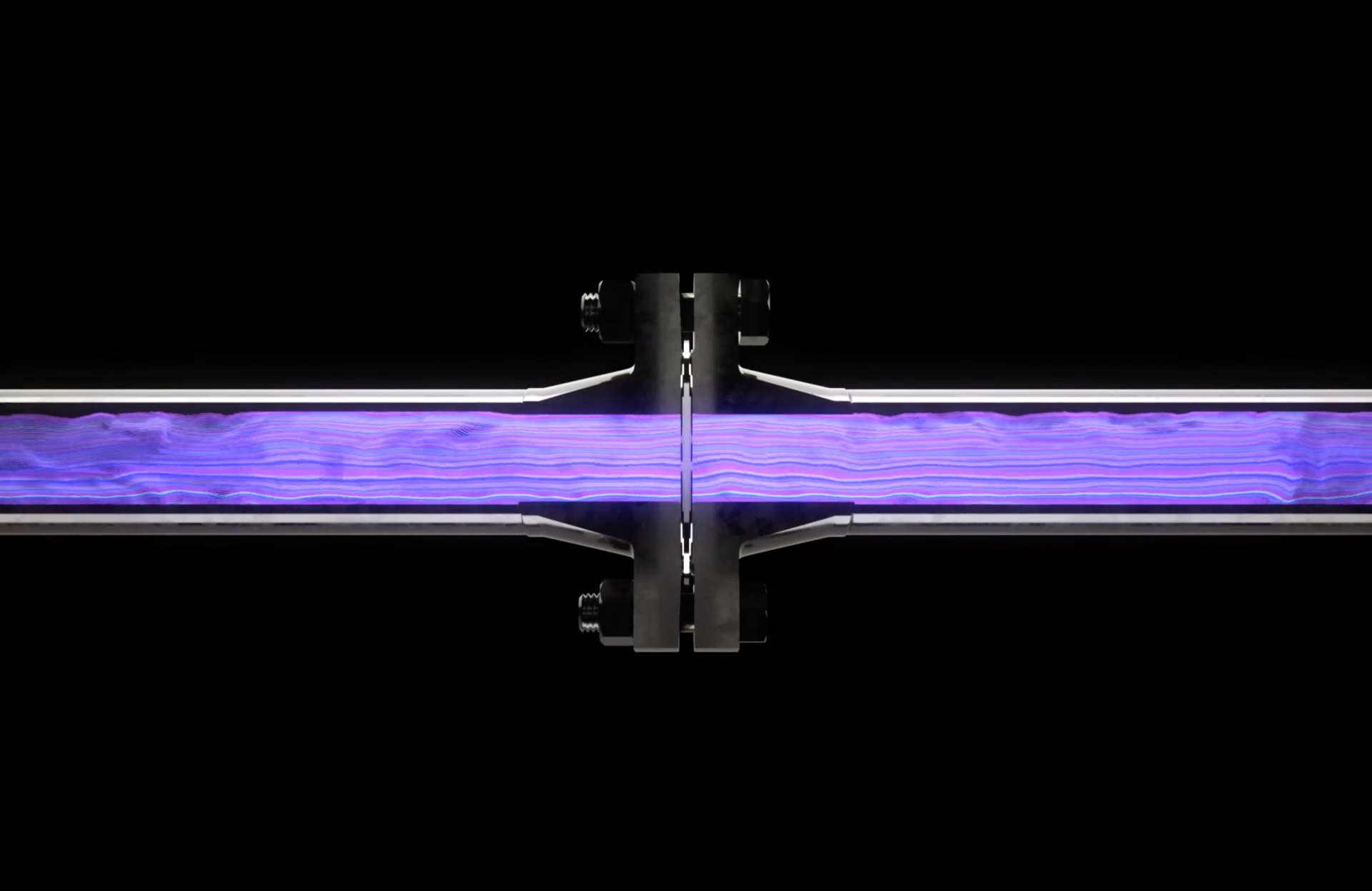

The customer planned to build a new stretch of pipeline with methane as the main process media. And part of the company’s strategy for methane mitigation, includes flange gaskets with exceptional tightness that don't degrade over time, guaranteeing a reduction of flange-born emissions.

The company had previously piloted DeltaV-SealTM gaskets on steam systems throughout the facility, and due to the success of stopping leakage and its relationship with Pipeotech, the customer was confident to use the same seals on its more critical methane system. Upon installation, the gasket's seal is enduring and gas-tight, eliminating fugitive emissions.

Installation of DeltaV-Seal has meant zero flange-born methane emissions, zero accidents and greatly reduced pipeline operating costs--no maintenance and periodical re-torquing required. While these seals decrease overall maintenance costs, they also meet the customer's long-term sustainability goal of eliminating methane emissions.