Industries

Power Generation

Seals at power plants are often exposed to highly fluctuating thermal and mechanical stress, independent of whether it is a nuclear or a fossil-fueled power plant. Thermal power stations generate steam. Our proprietary and patented industry-leading gasket technology meet the stringent demands of the power industry by providing containment, safety, and durability.

Applications

Leak-proof gaskets are absolutely crucial to the containment and integrity of a reactor, a tank, and the connecting piping.

Reactors

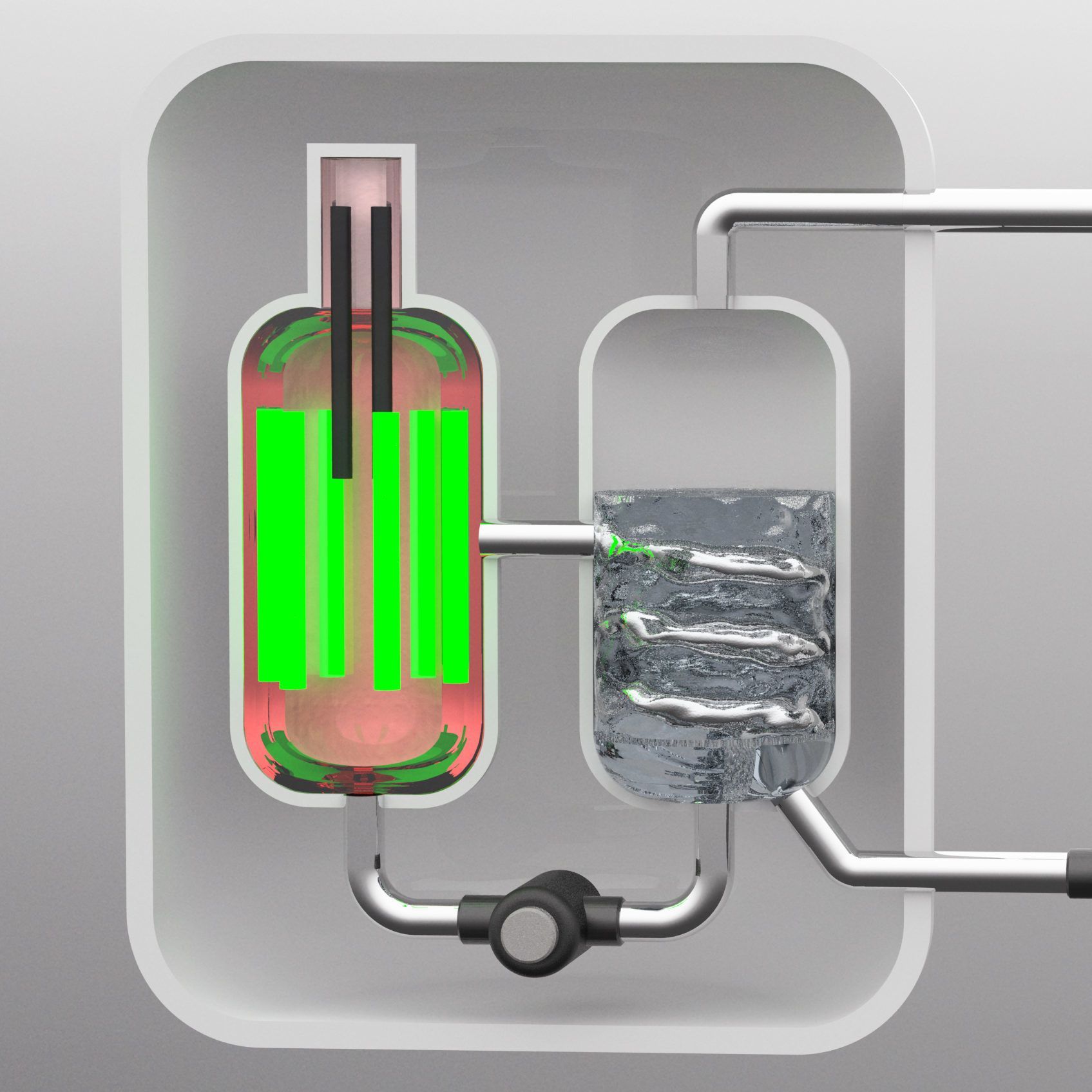

In a pressurized water reactor, the primary loop, which is contaminated with radioactive particles, is limited to the containment structure. Hot water is piped fromm the reactor to the steam generator to produce steam in the secondary systems. The media and pressure vary between the two loops, but it is only the type of material on the connections that determine what DeltaV-Seal to be used.

Boilers & steam generators

The DeltaV-Seal is ideal for handling temperature and pressure fluctuations, bolt stress relaxation and creep, as well as toxic and corrosive chemicals and media. We design boiler handhole and tube cap assemblies, and boiler manhole cover assemblies to your specification.

Boiler room and steam pipes

Steam leaks can lead to abnormally warm pipes and ambient temperatures, making the facility unsafe for workers. This problem is especially apparent in low-pressure steam systems where feedwater must be heated past the boiling point.

A ruptured steam pipe is a serious problem with the potential to cause bodily harm and serious financial risk. When a steam trap fails in the closed position, it can cause condensate to back up, increasing pressure levels and causing water hammer.

Use cases