Amended Technical Instructions on Air Quality Control (TA Luft) – What does it mean for Pipeotech and our customers?

Jo Shailes on Technical Articles · Feb 14, 2022

The Technical Instructions on Air Quality Control (TA-Luft), which have been revised in 2021, are a comprehensive instrument for German authorities to control air pollution.

They contain provisions to protect people and the environment from unacceptably high pollution originating from installations as well as requirements according to Best Available Techniques (BAT) to prevent adverse effects on the environment.

They set emission limits for all relevant air pollutants from most industrial installations. Existing installations must be upgraded to reflect the best available technology.

Pipeotech’s insights on stricter air emission limits and the wider remit in Germany

TA-Luft is one of Germany’s most important environmental legislations aside from the “Federal Pollution Control Act” (Bundes-Immisionsschutzgesetz). TA-Luft governs the licensing requirements for industrial plants and is aimed at reducing emissions of pollutants to improve air quality.

The previous iteration of TA-Luft dates from 2002, meaning that this overhaul has been long overdue. The revisions came into force in December 2021 and are intended to consider the latest air pollution treatment technology and most recent information on pollutants.

For example, TA-Luft 2021 are now including regulations for such variety of processes as biogas, wood pellet production and shredder systems for the first time, as well as new nationwide regulations to protect local residents from odour nuisance.

At Pipeotech, we have analysed the new regulations, and, in this article, we are summarising our insights for our customers. From our perspective, the largest impact related to the amendment of TA-Luft 2021 will be the impact on the gasket and sealing industries in terms of increased challenges to prove product tightness-over-time and under operating conditions in actual bolted flange joints (BFJ) in real piping/pipeline systems.

So, what are the main changes?

From Pipeotech’s perspective, key changes can be found in the section 5.2.6.3 Flange connections.

As a rule, flange connections should only be used if they are necessary for process engineering, safety, or maintenance purposes. In this case, technically tight flange connections are to be used. For a selection of seals and design of technically tight flange connections, the tightness class L 0.01 with the corresponding specific leakage rate ≤ 0.01 mg/m/s for the test medium helium or other suitable test media, e.g., methane shall be applied.

To continue reading download the article here

More from Technical Articles

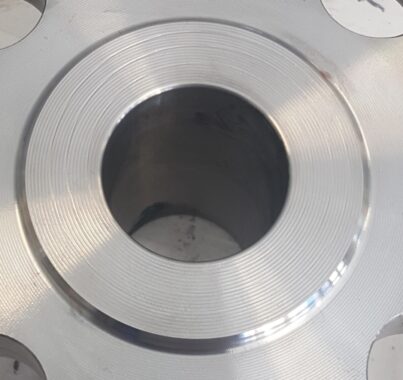

Modelling of Fluid Permeability at the Interface of the Metal-to-Metal Sealing Surface

James Knights on Technical Articles · Oct 28, 2024

The DeltaV-Seal is like no other gasket, and while replacing semi-metallic gaskets understanding how and why it performs so successfully is critical to unlocking the full potential of a bolted flange…

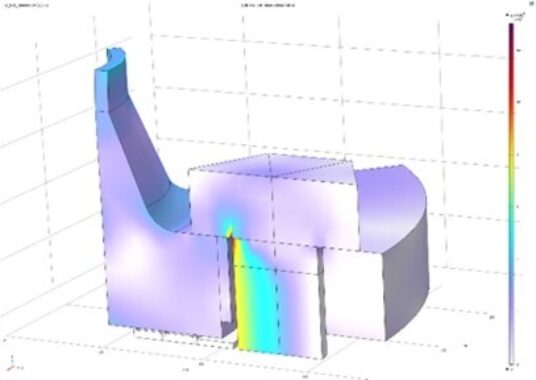

COMSOL Multiphysics FEA Modelling of Gasketed Bolted Flange Joints

James Knights on Technical Articles · Jul 08, 2024

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's…

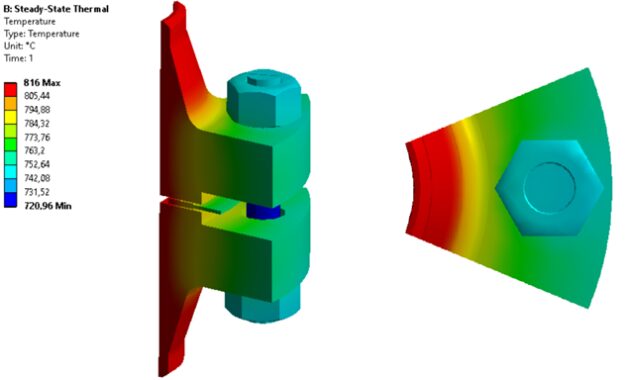

DeltaV-Seal 800HT - Assessment of high temperature pipework design for pilot plants

James Knights on Technical Articles · Dec 05, 2022

Ensuring the DeltaV-Seal™ gasket provides gas tight performance even when operating at temperatures as high as 880 °C (1616 °F).

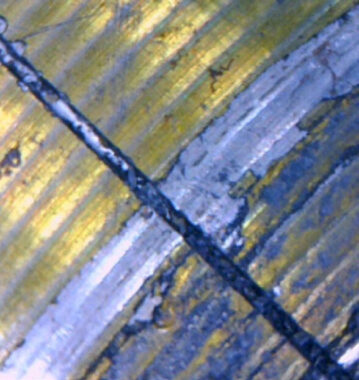

Stability and tightness of damaged flange joints with DeltaV-Seal Gaskets

Jo Shailes on Technical Articles · May 11, 2022

Imperfections on flange faces happen. With more and more companies adopting low emissions business practices, can damaged flange surfaces provide a suitable seal to meet environmental compliance?…

The importance of sealing materials in safe and efficient integrated fertilizer production

Jo Shailes on Technical Articles · Feb 11, 2022

The need to optimize fertilizer plant operations, driven by a range of external and internal influences, means that plant operators must be confident that all equipment is both reliable and high…