Reduce your VOC emissions with the DeltaV-Seal™

James Knights on · Oct 24, 2022

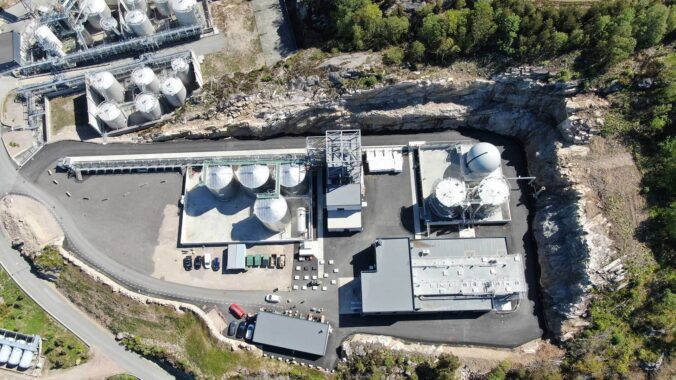

Globally there is a drive to consume less and emit fewer damaging chemicals into the atmosphere. Within the United States, businesses are being called to reduce fugitive emissions by at least 30% before 2030. There is a further global push for all countries to be net-zero emissions by 2050. The DeltaV-Seal™ has the potential to assist businesses in reducing their emissions and remaining compliant with their local laws meeting climate targets and improving their ESG Score Card value.

The United States Environmental Protection Agency (EPA) determined that leaking equipment, such as valves and connectors, is the largest source of volatile organic compound (VOC) emissions from petroleum refineries and chemical manufacturing facilities (EPA, 2007). VOCs include many industrial chemicals such as benzene and solvents such as toluene and xylene (NJDEP New Jersey Department of Environmental Protection, n.d.). When leaked into the atmosphere, these chemicals create long-term climate effects. In the past, these emissions have not been well regulated, so the EPA implemented a program to promote the reduction of emissions (EPA, 2007).

– The EPA has estimated that approximately 70,000 tons of VOCs are emitted yearly from leaks contributing to smog formation (EPA, 2007).

United States Environmental Protection Agency, 2007

Companies are required to reduce their VOC emissions through the Leak Detection and Repair (LDAR) program. LDAR regulation programs require companies to make equipment modifications and conduct regular monitoring to prevent leaks. With the proper implementation, companies are expected to reduce up to 96% of their emissions. Pipeotech's experience is that these programs can be costly to implement and only serve as short-term solutions given the degradation in performance of bolted flange joints sealed with traditional gaskets.

– 31% of uncontrolled VOC emissions in a petrochemical plant come from connectors (EPA, 2007).

United States Environmental Protection Agency, 2007

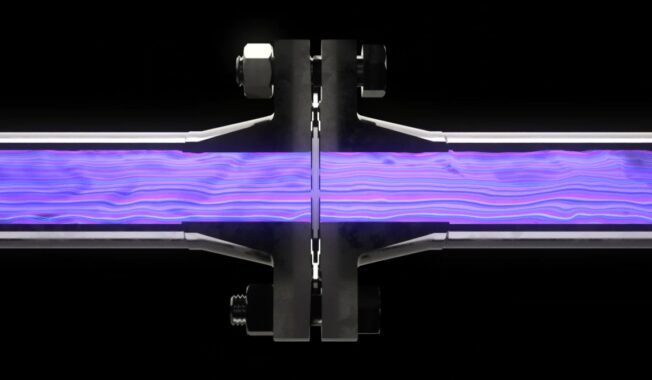

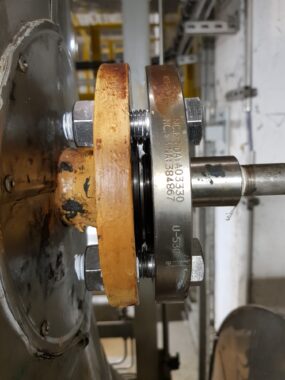

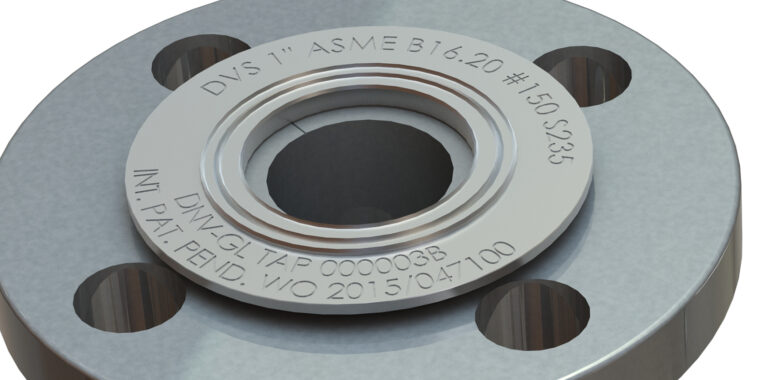

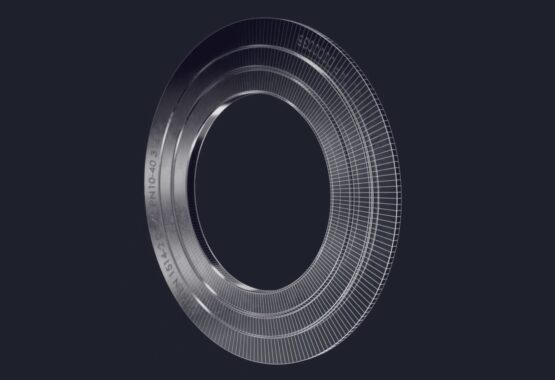

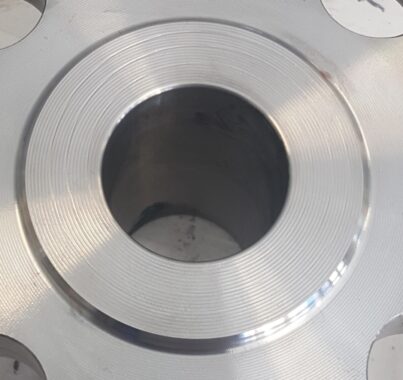

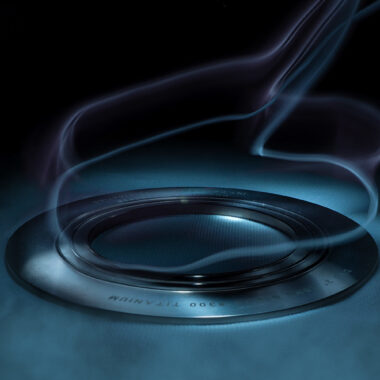

PIPEOTECH offers a different solution while still maintaining LDAR compliance. Installing the DeltaV-Seal™, a fully metallic sealing flange gasket, into bolted flange joints can significantly reduce these emissions with a gas-tight seal, which has been subject to stringent 3rd party testing at temperatures between -196 °C and +880 °C (-320 °F and 1616 °F). Utilising the DeltaV-Seal™ ensures gas-tight sealing, technically tight, durable, long-term, and superior sealing performance that helps operators to meet their emissions targets and improve their ESG Score Card value.

In addition to reducing emissions from bolted flange joints and helping businesses meet their target climate goals, the DeltaV-Seal™ flange gasket has been proven time and time again to reduce significantly overall maintenance costs, eliminate unplanned shutdowns and improve overall HSE TRIR numbers.

Not only can we assist businesses in removing emissions Pipeotech can also increase reliability and reduce costs.

Learn more about the DeltaV-Seal

Learn MoreMore from

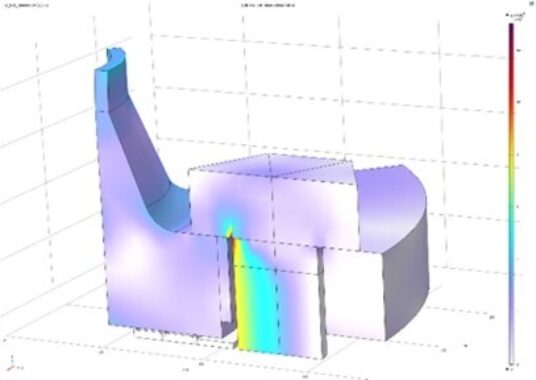

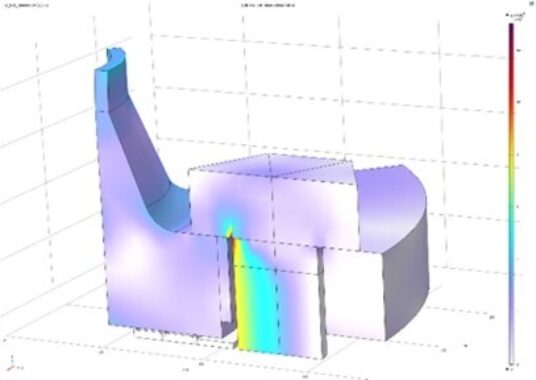

Modelling of Fluid Permeability at the Interface of the Metal-to-Metal Sealing Surface

James Knights on Technical Articles · Oct 28, 2024

The DeltaV-Seal is like no other gasket, and while replacing semi-metallic gaskets understanding how and why it performs so successfully is critical to unlocking the full potential of a bolted flange…

DNV Type Approval Certificate Renewed

James Knights on News · Oct 22, 2024

We're pleased to announce the renewal of our DNV Type Approval, valid until 2029. The DNV GL Type Approval (Certificate TAP000003B) celebrates the testing and dedication to achieving the tightest…

DeltaV-Seal increases available up-time on Ammonium Nitrate flanges

James Knights on Case Studies · Sep 16, 2024

Legacy semi-metallic gaskets leak, this is particularly visible on Ammonium Nitrate flanges. The DeltaV-Seal provides a significantly tighter seal than legacy gaskets, enabling fertilizer…

DeltaV-Seal - Preventing emissions of NOX gas during fertilizer manufacture

James Knights on Case Studies · Sep 16, 2024

NOX is considered an indirect greenhouse gas, with strict PPM values for the amount of emissions a chemical plant can release. The DeltaV-Seal with its tight and durable seal prevents emissions of…

DeltaV-Seal - Reducing fugitive emissions in the Permian Basin

James Knights on Case Studies · Jul 22, 2024

The United States Clean Air Act (CAA) is the comprehensive federal law regulating emissions from stationary and mobile sources. Among other things the CAA authorises the United States Environment…

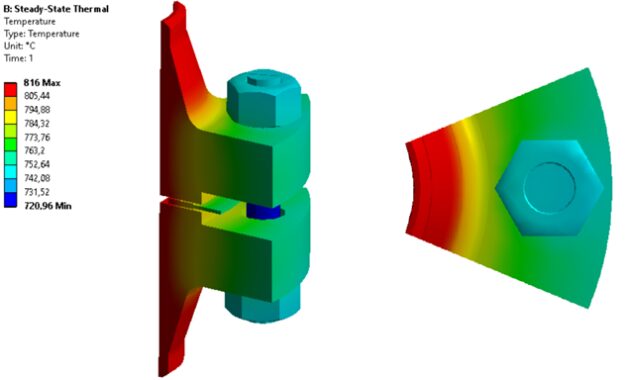

COMSOL Multiphysics FEA Modelling of Gasketed Bolted Flange Joints

James Knights on Technical Articles · Jul 08, 2024

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's…

COMSOL Multiphysics FEA Modelling of Gasketed Bolted Flange Joints

James Knights on News · Jul 08, 2024

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's…

DeltaV-Seal 304L ASME Installation Handbook

James Knights on Installation Guides · May 21, 2024

Installation Handbook for the DeltaV-Seal flange gasket in 304L Stainless Steel - ASME Sizes.

The simple replacement for Spiral Wound and Kammprofile gaskets

James Knights on Videos · Mar 20, 2024

The DeltaV-Seal gasket replaces spiral wound and Kammprofile gaskets with a metal-to-metal seal without any of the challenges of traditional sealing technologies. As a metal-to-metal seal the leakage…

DeltaV-Seal

James Knights on Videos · Mar 20, 2024

The DeltaV-Seal provides a metal-to-metal seal, unlike any other seal. With a combination sealing rings and a small surface area the DeltaV-Seal deforms to the flange. Traditional metallic seals…

DeltaV-Seal 304L EN Installation Handbook

James Knights on Installation Guides · Sep 08, 2023

Installation Handbook for the DeltaV-Seal flange gasket in 304L Stainless Steel - EN Sizes.

Best Available Technology to reduce ATEX zones, increase reliability, and improve safety within a refinery

James Knights on Case Studies · Jul 21, 2023

Europe’s most advanced refinery wanted to further pioneer by only utilizing Best Available Technology to ensure a safe and reliable operation with minimal impact on the environment, enhanced…

Pipeotech launch new 304L stainless steel DeltaV-Seal for nitric acid service

James Knights on News · Jun 21, 2023

Working with the chemical industries it is clear Nitric Acid is a particularly challenging chemical to keep within bolted flange joints. Current industry practice on bolted flange joints containing…

DeltaV-Seal 304L

James Knights on Product Information · Jun 15, 2023

Product information data sheet for DeltaV-Seal 304L

FPSO & Marine - DeltaV-Seals ensure the safe and reliable operation of inert gas systems

James Knights on Case Studies · Mar 21, 2023

A market-leading expert for the maritime industry manufactures a range of inert gas generators to suit their client's needs. Vessels carrying cargo-producing hydrocarbon vapors require inert gas…

Frequently Asked Questions

James Knights on News · Mar 17, 2023

The DeltaV-Seal is revolutionising static sealing, one gasket at a time. The gasket provides the tightness and durability of a metal-to-metal seal with the ease of application of a spiral wound,…

Proposed European PFAS ban officially submitted – it’s potential impact on PTFE gaskets.

James Knights on News · Mar 17, 2023

On the 13 January 2023, The Netherlands, Germany, Denmark, Sweden and Norway took the first formal step towards a European ban on polyfluoroalkyl substances (PFAS) by jointly submitting a restriction…

Preventing nitrous gas leakage at a Thermowell instrument flange joint

James Knights on Case Studies · Mar 09, 2023

On a Thermowell instrument coupling flange joint a previous semi-metallic gasket required maintenance intervention 7 times in three-and-a-half years. Switching from a semi-metallic gasket to the…

We're growing - and moving to a bigger office space!

James Knights on News · Mar 06, 2023

We are excited to announce that Pipeotech’s Oslo team is moving to a new location within Oslo. The big reason? We are growing in both the number of clients and number of applications where a…

Semi Conductor application for Nitrogen and Oxygen gas purifiers

James Knights on Case Studies · Feb 27, 2023

One of the world's leading semiconductor manufacturers in South Korea required a carbon-free, bacteria and virus-tight gasket capable of withstanding temperatures up to 500°C. The DeltaV-Seal™…

ATEX Zoning reduction & Equipotential bonding possible with the DeltaV-Seal

James Knights on Case Studies · Jan 09, 2023

Recycling metallic canisters containing flammable gases to prevent the emission of the gases to the environment and recycle the metallic packing material.

DeltaV-Seal Gaskets for peroxide service featured in Fluid Handling Pro

James Knights on News · Dec 21, 2022

Pipeotech's project with a global manufacturer of peroxide has been featured within Fluid Handling Pro. The article details the design considerations for a gasket utilized in an extremely pure…

DeltaV-Seal S235 EN Installation Handbook

James Knights on Installation Guides · Dec 05, 2022

Installation Handbook for the DeltaV-Seal flange gasket in S235 Carbon Steel - EN Sizes

DeltaV-Seal 316L EN Installation Handbook

James Knights on Installation Guides · Dec 05, 2022

Installation Handbook for the DeltaV-Seal flange gasket in 316L Stainless Steel - EN Sizes

DeltaV-Seal S235 ASME Installation Handbook

James Knights on Installation Guides · Dec 05, 2022

Installation Handbook for the DeltaV-Seal flange gasket in S235 Carbon Steel - ASME Sizes

DeltaV-Seal 316L ASME Installation Handbook

James Knights on Installation Guides · Dec 05, 2022

Installation Handbook for the DeltaV-Seal flange gasket in 316L Stainless Steel - ASME Sizes

DeltaV-Seal 800HT - Assessment of high temperature pipework design for pilot plants

James Knights on Technical Articles · Dec 05, 2022

Ensuring the DeltaV-Seal™ gasket provides gas tight performance even when operating at temperatures as high as 880 °C (1616 °F).

Reducing ATEX zoning within a biogas plant

James Knights on Case Studies · Nov 11, 2022

Local regulation of a biogas plant in Western Europe required ATEX zoning. Utilizing several technical standards including EN1127, EN1591, and Pipeotech's extensive library of product testing, it has…

Pipeotech Q3 Newsletter

James Knights on News · Oct 20, 2022

Another quarter is in the books here at Pipeotech. Q3 brought many opportunities for the company. Engineers and executives met with clients across the globe and attended various events to share the…

Cleaned gaskets within a peroxide system of a chemical processing plant

James Knights on Case Studies · Oct 11, 2022

Ensuring product quality and plant safety with a clean, bespoke, tight, and durable seal. The DeltaV-Seal enabled a manufacturer of peroxide to ensure their product was made safely and was free of…

Technical Paper: Long lasting gaskets for ammonium nitrate and nitric acid applications.

James Knights on · Oct 10, 2022

Pipeotech was pleased to attend the October 2022 Ammonium Nitrate Nitric Acid (ANNA) Conference in Houston, TX, USA during which Pipeotech CTO Jan Oredsson presented a technical paper on the…

Welcoming Henrik Borge and Przemyslaw Jaszak (Pawel) to the Pipeotech team

Jo Shailes on · Jul 06, 2022

Our Engineering team is growing. Reporting to the Company CTO – Mr Jan Oredsson, It is our pleasure to welcome Henrik Borge and Przemyslaw Jaszak (Pawel) to our team.

DeltaV-Seal 800HT

Jo Shailes on Product Information · Jun 17, 2022

Product information data sheet for DeltaV-Seal 800HT

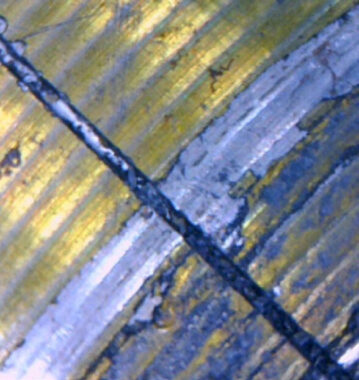

Stability and tightness of damaged flange joints with DeltaV-Seal Gaskets

Jo Shailes on Technical Articles · May 11, 2022

Imperfections on flange faces happen. With more and more companies adopting low emissions business practices, can damaged flange surfaces provide a suitable seal to meet environmental compliance?…

DeltaV-Seal S235 - Gasket Data

Jo Shailes on Product Information · Apr 07, 2022

Product information data sheet for DeltaV-Seal S235

Amended Technical Instructions on Air Quality Control (TA Luft) – What does it mean for Pipeotech and our customers?

Jo Shailes on Technical Articles · Feb 14, 2022

The Technical Instructions on Air Quality Control (TA-Luft), which have been revised in 2021, are a comprehensive instrument for German authorities to control air pollution.

The importance of sealing materials in safe and efficient integrated fertilizer production

Jo Shailes on Technical Articles · Feb 11, 2022

The need to optimize fertilizer plant operations, driven by a range of external and internal influences, means that plant operators must be confident that all equipment is both reliable and high…

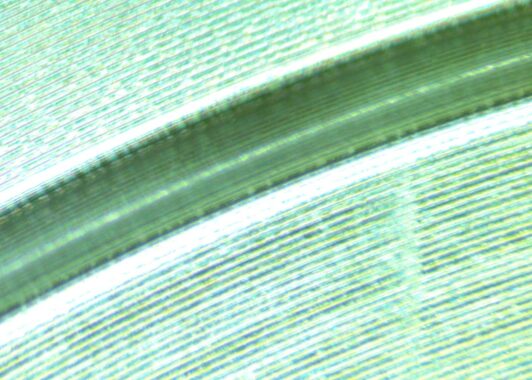

The impact of using DeltaV-Seal™ on flange surfaces

Jo Shailes on Technical Articles · Feb 11, 2022

Pipeotech has conducted flange surface profile measurements in cooperation with Sintef/DNV to investigate the impact of DeltaV-Seal on flange surfaces in bolted flange joints (BFJ).

DeltaV-Seal 316L - Gasket Data

Jo Shailes on Product Information · Feb 11, 2022

Product information data sheet for DeltaV-Seal 316L

Pipeotech, featured in Fluid Handing Pro

Jo Shailes on News · Nov 15, 2021

Vibration Analysis Part of the DNV Type Approval for the Pipeotech DeltaV-Seal The weakest link in industrial piping systems is the gasket. Conventional semi-metallic gasket technologies are not able…

Corporate environmental responsibility ‘done right’ with long-term methane mitigation by design

Jo Shailes on Case Studies · Nov 02, 2021

Methane is one of the most potent greenhouse gases and avoiding leakage is a priority when using methane systems. Methane also ignites easily, so there are clear and immediate HSE incentives for…

Gasket ensures a long-lasting seal

James Knights on Case Studies · Nov 02, 2021

In manufacturing fertilizer, ammonium nitrate is added to the process, and traditional, spiral wound and Gylon gasket technology often deteriorate in these conditions, resulting in leaks. This is…

ATEX zoning unnecessary with DeltaV-Seal™

Jo Shailes on Case Studies · Nov 01, 2021

During final assembly in the factory, cars are filled with fuel before being transported to their final destination. To facilitate this, fuel lines run throughout the facility. However, along the…

DeltaV-Seal™ stops flammable leakage, prevent fires

Jo Shailes on Case Studies · Nov 01, 2021

In facilities that use hot oil heat transfer fluid systems, fire hazards are a significant challenge due to the combination of organic combustible liquids, which run at temperatures above their flash…

DeltaV-Seal™ prevent fires, promote safe environment

Jo Shailes on Case Studies · Nov 01, 2021

The use of hot oil systems in manufacturing presents challenges when traditional gaskets breakdown and cause leakage. As liquids in the system are kept at a temperature above their flash point, when…

DeltaV-Seal™ prevents leaks and pipe corrosion

Jo Shailes on Case Studies · Nov 01, 2021

In district heating and cooling, generic spiral wound gaskets frequently cannot cope with the cyclical temperature conditions and often fail, leading to leakages and corrosion of the pipeline. This…

DeltaV-Seal™ performs under extreme marine conditions

Jo Shailes on Case Studies · Nov 01, 2021

Importing ship-to-shore Liquefied Natural Gas (LNG) requires robust and efficient pipeline seals that are compliant with high environmental standards. The thermal cycling caused by the cryogenic…

DeltaV-Seal™ reduces greenhouse emissions

Jo Shailes on Case Studies · Nov 01, 2021

In fertilizer production, high-quality phosphorus fertilizers require nitric acid as a key ingredient, which is usually synthesized via the Ostwald process on-site (oxidizing of ammonia before…

Pipeotech, featured in Sealing Technology & World Pumps

Jo Shailes on News · Oct 27, 2021

Following extensive leakage testing, carried out under cryogenic conditions in a laboratory programme, Pipeotech has extended coverage all the way down to applications running at a temperature of…

Valve World features DeltaV-Seal™

Geir Otto Amundsen on News · Sep 15, 2021

In July 2021, one of the sealing industry's most widely circulated publications, Valve World, featured Pipeotech CTO Jan Oredsson inspecting a DeltaV-Seal gasket on its front cover, hailing Pipeotech…

Andrew Patrick takes over as Pipeotech interim CEO

Geir Otto Amundsen on News · Jun 23, 2021

Pipeotech has appointed Andrew Patrick as the company’s interim chief executive following the resignation of outgoing CEO Henrik Sollie. Patrick steps into the interim role from his current position…

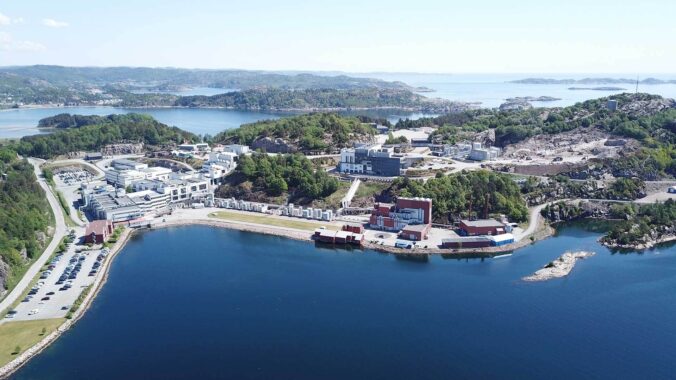

In conversation with: Odd Skagestad, GE Healthcare Lindesnes

Geir Otto Amundsen on Case Studies · Jun 02, 2021

We recently spent some time talking with technical engineer Odd Skagestad from GE Healthcare Lindesnes about how DeltaV-Seal™ technology has impacted operations at a world-leading pharmaceutical…

Cryogenic milestone for DeltaV-Seal™

Geir Otto Amundsen on News · Mar 31, 2021

Pipeotech gasket, DeltaV-Seal™ is engineered for long term use, all the way down to applications running at -196°C, based on stellar results of cryogenic leakage tests at a pre-eminent European…

DeltaV-Seal™ - The end to fugitive emissions?

Geir Otto Amundsen on News · Mar 16, 2021

At Pipeotech we believe that the concept of 'acceptable leakage' is unacceptable and that flange-born fugitive emissions are an avoidable threat. As part of our mission to spread this message it was…

Pipeotech’s reach goes atomic

Geir Otto Amundsen on Case Studies · Jan 05, 2021

Pipeotech has taken gasket tightness to new microscopic levels by supplying DeltaV-Seal™ to European Spallation Source, the world’s most powerful neutron source, in Lund, Sweden. The new research…

Corrosion and integrity specialist Jan Oredsson joins Pipeotech

Geir Otto Amundsen on News · Dec 02, 2020

Pipeotech has sealed the deal on an exciting new addition to its team by bringing in internationally recognized pipeline integrity and corrosion expert Jan Oredsson.Oredsson has extensive experience…

VARD finds the perfect fit

Jo Shailes on Case Studies · Nov 11, 2020

Norwegian-based shipbuilder VARD has been installing Pipeotech’s DeltaV-Seal™ in its vessels since 2016 and the cost-saving benefits have been very clear to Johny Morland, Principal Engineer, QA and…

Pipeotech recruits Andrew J. Patrick as new Head of Business Development

Geir Otto Amundsen on News · Oct 05, 2020

Pipeotech is looking to “supercharge” its global growth with the recruitment of Andrew Patrick to the new role of Head of Business Development. Patrick, previously EVP Global Sales at Clock Spring…

Pipeotech joins the European Sealing Association

Geir Otto Amundsen on News · Jun 28, 2020

Pipeotech is pleased to announce that it has become a member of the European Sealing Association.Established in 1992 as a non-profit making trade association, The European Sealing Association…

Corrosive influence - The dangers of galvanic corrosion for pipelines

Geir Otto Amundsen on Case Studies · Apr 22, 2020

Prevention is always better than a cure. Avoiding issues in the first place, rather than attending to them once they’ve occurred, is plain common sense. So why do so many industrial facilities…

To boldly go... Pipeotech joins the Innovation Norway, Explorer

Geir Otto Amundsen on News · Apr 22, 2020

We’re pleased to announce that at the beginning of 2020, Pipeotech joined the ranks of one of Norwegian Industry’s most exclusive clubs, The Explorer. Opened by Norwegian Prime Minister Erna Solberg…

Pipeline safety – How gasket choices can mitigate health and safety risks

Geir Otto Amundsen on Case Studies · Jan 31, 2020

Nothing is as important as health and safety when it comes to industrial facilities. However, a critical component in piping systems is often overlooked, viewed as a consumable rather than a key to…

Stopping expensive leakages at historic brewing facility

Geir Otto Amundsen on Case Studies · Jan 31, 2020

With the title of ‘the oldest brewery in Norway’, the Aass brewery is about as close as it gets to being a Norwegian institution. Situated on the banks of the river in the busy port city of Drammen…

From subsea to life on land - gasket technology follows Darwinism

Geir Otto Amundsen on News · Aug 28, 2019

As featured by Yahoo Finance news via Cision PRNewswireMetal-to-metal sealing technology is a technique that had previously been reserved for subsea oil and gas applications where meeting the most…

The seal of integrity (a feature article written by Industry Networker Magazine)

Geir Otto Amundsen on News · Jul 01, 2019

In a recent article published by Industry Networker Magazine, Pipeotech and theDeltaV-Seal™ are recognized for significant technological enhancements towards safety, efficiency, cost reduction, and…

DeltaV-Seal™ replaces kammprofile gaskets at critical distribution facility

Jo Shailes on Case Studies · Jun 12, 2019

After a long relationship utilizing kammprofile gasket technology, Norwegian LPG distributor PrimaGaz Norge AS has decided to abandon the old kammprofile gasket design in favor of the new DeltaV-Seal…

Flare tip leakage is too hot to handle for the competition

James Knights on Case Studies · May 15, 2019

Pipeotech was called upon to provide a solution for Flare Tip flange leak in the North Sea. A North Sea Operator came to Pipeotech with a problem affecting a Flare line on their platform. This was…

Exceeding gas-tight sealing strengths and eliminating ATEX zones

Geir Otto Amundsen on Case Studies · May 08, 2019

Gaskets seals are generally the consumables often selected at the last moment in a design project and carry few expectations. Although viewed as less significant, this consumable can have the most…

Intergas exclusively use DeltaV-Seal™

Jo Shailes on Case Studies · Mar 26, 2019

Following a highly successful test period, Intergas AS has announced that the DeltaV-Seal has been named as their exclusive seal of choice for all current and future liquefied natural gas operations.…