From subsea to life on land - gasket technology follows Darwinism

Geir Otto Amundsen on News · Aug 28, 2019

As featured by Yahoo Finance news via Cision PRNewswire

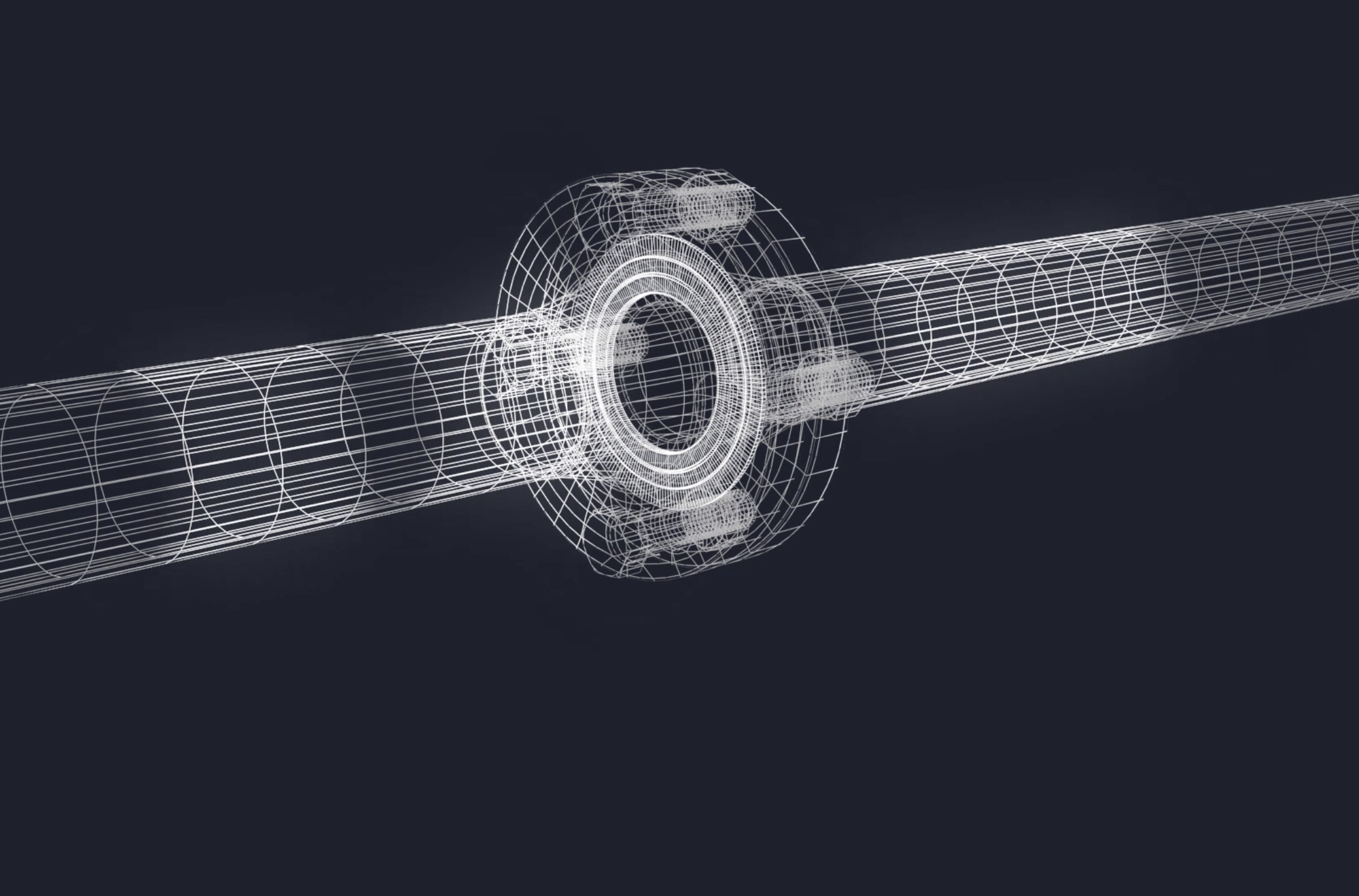

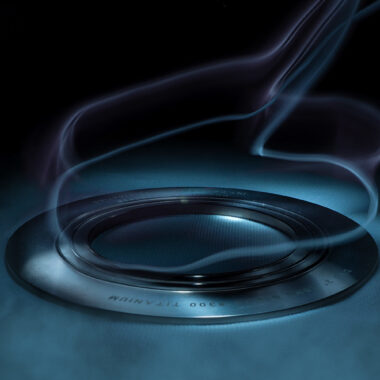

Metal-to-metal sealing technology is a technique that had previously been reserved for subsea oil and gas applications where meeting the most extreme operational criteria has always been required. Such criteria demand that any equipment, tools, and sealing technology must withstand extreme crushing depths where environmental pressures and temperatures will easily destroy any object that falls victim to their reach. However, now this revolutionary technology has made landfall and is changing the landscape of onshore operations. It has quickly begun presenting the opportunity to help resolve serious challenges such as, fugitive emission, as well as significantly reducing risk factors, and improving the bottom line of business.

The company responsible for bringing this technological evolution to land is the Norwegian based company Pipeotech AS. Adapted directly from the same subsea technology, the DeltaV-Seal™ offers manufacturers and production facilities alike significant enhancements in operations across a wider spectrum of function than competing spiral-wound or kammprofile gasket technologies. Difficulties associated with these older sealing technologies motivated Pipeotech engineers to take up the challenge of developing a new technology that would replace them. Some of the primary goals were to develop a gasket that would last significantly longer, exceed a gas-tight strength, and eliminate the need for maintenance. All three of these contribute to significant reductions in ecological harm, employee risk, and operating expenditures.

Removing the weakest links

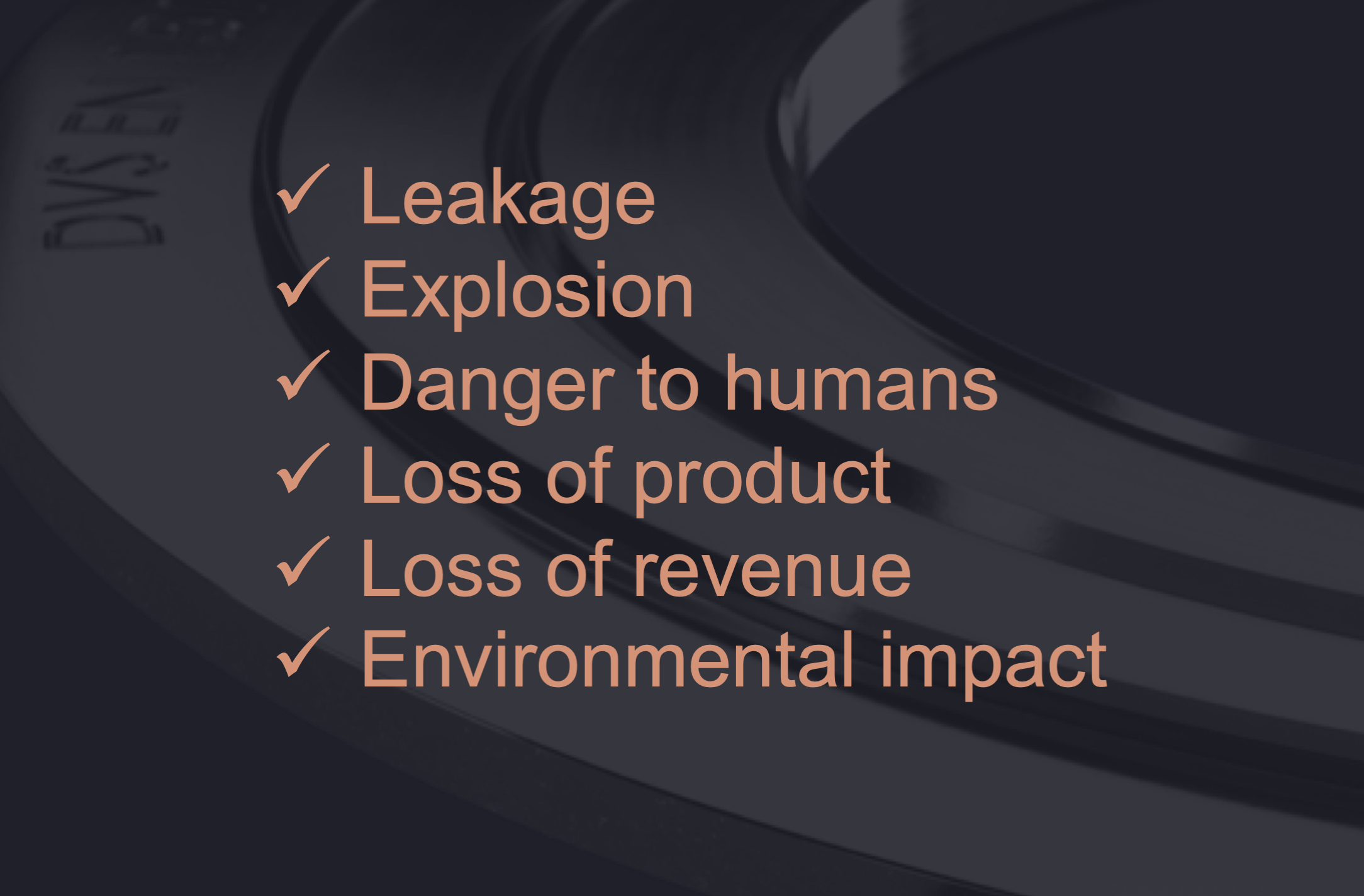

Typically, a gasket fails to capture much attention, because it is thought of as a small detail from a macro perspective in piping infrastructure design. Serving as a meeting point between two pipes, flanges are identified as a risk in the construction or update of any production facility. However, through the usage of spiral-wound and kammprofile technologies, most production facilities currently anticipate or accept certain levels of leakage as normal. This approach often has gaskets being treated as a consumable.

Both of these technologies offer similar lifespans and an equal amount of required maintenance while in operation. As a result, gaskets are selected as a last detail for the final facility design, with the overall emphasis being placed on gasket cost. The most effective gasket sealing technology plays a much larger role in daily operations beyond containing leaks. When either of these sealing technologies are utilized, a true gas-tight seal is never truly obtained. This leads to the possibility of leakage points which being created, posing various risks such as;

What is so special about this new technology over existing gasket technologies?

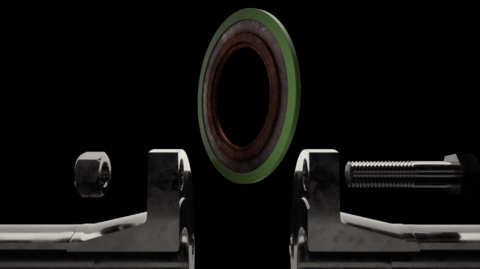

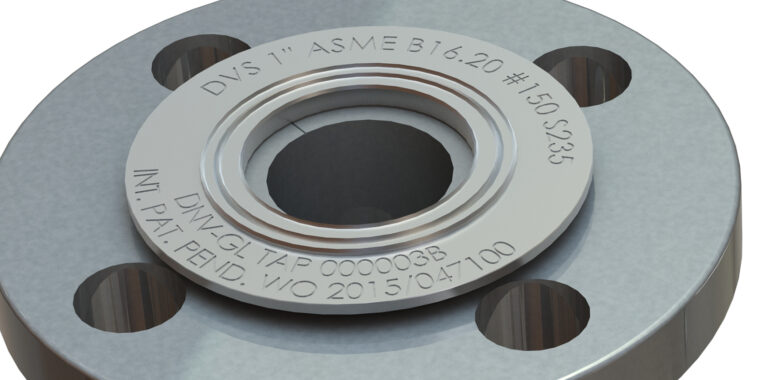

The first differentiating characteristic is the metal-to-metal design. A metal gasket offers far more flexibility in practical applications. Utilizing metal allows for a stronger seal which is more resistant to warping, however this gasket technology is not only produced in one metal material. Each gasket is produced from the metal material which matches the material of the joining flanges. This is done for multiple reasons, the first is for maintaining sealing strength through internal or external environmental temperature changes of the pipe.

When metal is subjected to temperature changes it expands or contracts. These circumstances then require a gasket to both expand or contract along with the flange. Since different metal materials react differently to temperature change, producing gaskets from a matching metal material is required. This enables the gasket and flange to be matched in the rate of expansion or contraction, while maintaining maximum sealing strength.

It boasts three unique, sharp sealing rings that deform on installation, filling any surface irregularities on pipe flanges to form the perfect seal

Another reason for the metal construction is that it enables for an entirely different level of sealing strength to be achieved. The specially engineered metal rings incorporated into the gasket design adapts to the surface of the flange, creating a smarter seal. Under torqued pressure, the metal rings deform and adapt to the exact landscape of the flange surface, resulting in a sealing strength which exceeds the classification of gas-tight sealing strengths (equal to 10-08 mbar l/s). Interestingly, this type of sealing strength is achieved and maintained without causing any damage or deformation to the flange.

The quality and strength of the seal was confirmed through helium tests conducted by DNV GL. Helium was used in the test because of the inherent difficulty in sealing against leaks. Leaks occur easier with Helium because the molecules are smaller than oxygen molecules, making it harder to contain in a given environment. A common example of helium's propensity to escape can easily be observed with an ordinary birthday balloon over the time period of a few days. Regardless of whether the balloon is made of rubber or plastic, the helium molecules are able to pass through the retaining material unlike oxygen, which has larger molecules, making it more containable.

The test revealed that even with surface scratches as deep as 0.3 mm, spanning across the entire raised face surface of the flange remained completely gas-tight. A technological benefit such as this presents users with the ability of prolonging the lifespan of their current piping infrastructure. This can also be applied to flanges which may have previous damage equal to or less than 0.3mm in depth.

Challenging the ruling search & repair approach

One of the most demanding aspects in the operational lifespan of kammprofile or spiral-wound technologies is the level of required maintenance. Due to the materials used in their construction, both technologies have the propensity to degrade over time, compromising the security of a flange. However, what if these difficulties and characteristics were eliminated?

The DeltaV-Seal utilizes a solid metal construction, which is water cut, and finished through a CNC machining process. By producing metal gaskets in this manner, heat is completely eliminated from the process. Although some metal products can draw strength from heat treatment, gaskets tend to get more prone to failure, as heat adversely effects the sealing properties. When utilizing metal gaskets, the governing principle should be to choose a metal which matches the flange material, as this also prevents galvanic corrosion from forming in the flange. By using a matching, metal gasket like the DeltaV-Seal, flanges remain uncontaminated of any outside material. This enables the gasket to be utilized without requiring any maintenance, including cleaning.

Soft graphite seals in particular are known for leaving behind contaminated debris after they are removed. Due to the proprietary metal construction, the DeltaV-Seal never degrades or changes properties.

Why leak and fix when you can install and forget?

This means not only does the gasket last significantly longer than other technologies, but it also eliminates the need to clean away material that other gasket types would leave behind. Maintenance on one joint (the meeting point of two flanges) can cost a company many man hours in labor, reduced production, and increase risk. For any facility with hundreds or thousands of flanges, this presents significant costs. However, when this challenge is eliminated, as it is with the new technology of the DeltaV-Seal, the costs associated with unscheduled maintenance are also eliminated. This enables productivity levels to be higher and more consistent. Since this is a metal-to-metal technology, it utilizes no soft sealing material like graphite gaskets do. This means that once a facility has installed it, as long as the correct installation procedure and torque specifications are followed, the bolts will never need to be retightened. They will retain the same clamping strength until the day the gasket is replaced.

When the time comes for a scheduled flange inspection or a gasket replacement, all that is required is to open the flange, inspect as necessary and install the new gasket. This eliminates downtime and costs caused by flange cleaning. To ensure proper centering on the flange, the outer ring of the gasket serves as a guide to position itself for the correct placement on the flange face. Correct placement of a gasket on a flange is paramount for achieving maximum sealing strength.

What about safety enhancements?

Naturally one of the largest threats of any vessel, operating at sea is fire. The danger and destructive power are more fiercely fought than any other threat. However, this presents one of the key safety benefits, which the DeltaV-Seal technology has brought to on-shore operations. The significant sealing pressure combined with its machined, metal construction enables the gasket to be fire and blowout proof. In tests conducted by German based AMTEC (Advanced Measurement Messtechnischer Service GmbH) the DeltaV-Seal showed amazing resilience against the threat of being compromised by direct flame or scorching temperatures.

The results of various tests showed that even after being directly exposed to flames for 30 minutes, the gasket withstood temperatures in excess 650° Celsius (1202° F) at 40 bar of pressure. This enabled the gasket to earn the API 6FB fire test approval. The API 6FB approval is an integral benefit to have for both off-shore and on-shore operations which involve engineers dealing with corrosion damaged flange faces or in challenging environments, such as highly flammable hydrocarbon containing systems. The same test results also showed that after 30 minutes of direct exposure, the gasket released only 1% of the allowed amount.

How can an unassuming piece of metal revolutionize so much? This new generation of gasket technology is transforming the opinion that industry has long since held of gasket design. No longer is a gasket just a tool in the implementation of industrial production. This is the type of technology that industry is constantly waiting on to arrive, the type that allows for big leaps forward in efficiency, productivity, and safety. This technology has transformed the gasket into a cost saver, a risk reducer, and an environmental protector. It gives equal capabilities to both big and small facilities to cut significant costs in operations and maintenance by millions of dollars over time. Taken together, these capabilities continue to demonstrate the advantage of utilizing the metal-to-metal design for countless industrial operations.

Want to learn more about how DeltaV-Seal can help you?

Contact usMore from News

DNV Type Approval Certificate Renewed

James Knights on News · Oct 22, 2024

We're pleased to announce the renewal of our DNV Type Approval, valid until 2029. The DNV GL Type Approval (Certificate TAP000003B) celebrates the testing and dedication to achieving the tightest…

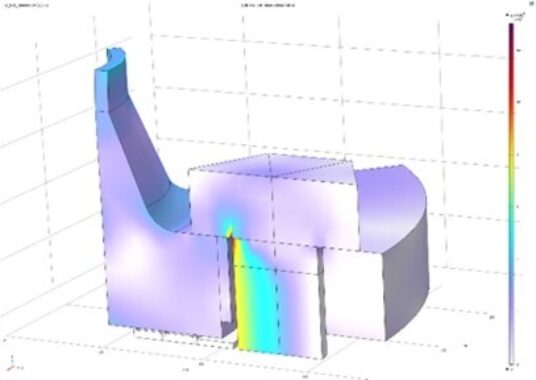

COMSOL Multiphysics FEA Modelling of Gasketed Bolted Flange Joints

James Knights on News · Jul 08, 2024

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's…

Pipeotech launch new 304L stainless steel DeltaV-Seal for nitric acid service

James Knights on News · Jun 21, 2023

Working with the chemical industries it is clear Nitric Acid is a particularly challenging chemical to keep within bolted flange joints. Current industry practice on bolted flange joints containing…

Frequently Asked Questions

James Knights on News · Mar 17, 2023

The DeltaV-Seal is revolutionising static sealing, one gasket at a time. The gasket provides the tightness and durability of a metal-to-metal seal with the ease of application of a spiral wound,…

Proposed European PFAS ban officially submitted – it’s potential impact on PTFE gaskets.

James Knights on News · Mar 17, 2023

On the 13 January 2023, The Netherlands, Germany, Denmark, Sweden and Norway took the first formal step towards a European ban on polyfluoroalkyl substances (PFAS) by jointly submitting a restriction…

We're growing - and moving to a bigger office space!

James Knights on News · Mar 06, 2023

We are excited to announce that Pipeotech’s Oslo team is moving to a new location within Oslo. The big reason? We are growing in both the number of clients and number of applications where a…

DeltaV-Seal Gaskets for peroxide service featured in Fluid Handling Pro

James Knights on News · Dec 21, 2022

Pipeotech's project with a global manufacturer of peroxide has been featured within Fluid Handling Pro. The article details the design considerations for a gasket utilized in an extremely pure…

Pipeotech Q3 Newsletter

James Knights on News · Oct 20, 2022

Another quarter is in the books here at Pipeotech. Q3 brought many opportunities for the company. Engineers and executives met with clients across the globe and attended various events to share the…

Pipeotech, featured in Fluid Handing Pro

Jo Shailes on News · Nov 15, 2021

Vibration Analysis Part of the DNV Type Approval for the Pipeotech DeltaV-Seal The weakest link in industrial piping systems is the gasket. Conventional semi-metallic gasket technologies are not able…

Pipeotech, featured in Sealing Technology & World Pumps

Jo Shailes on News · Oct 27, 2021

Following extensive leakage testing, carried out under cryogenic conditions in a laboratory programme, Pipeotech has extended coverage all the way down to applications running at a temperature of…

Valve World features DeltaV-Seal™

Geir Otto Amundsen on News · Sep 15, 2021

In July 2021, one of the sealing industry's most widely circulated publications, Valve World, featured Pipeotech CTO Jan Oredsson inspecting a DeltaV-Seal gasket on its front cover, hailing Pipeotech…

Andrew Patrick takes over as Pipeotech interim CEO

Geir Otto Amundsen on News · Jun 23, 2021

Pipeotech has appointed Andrew Patrick as the company’s interim chief executive following the resignation of outgoing CEO Henrik Sollie. Patrick steps into the interim role from his current position…

Cryogenic milestone for DeltaV-Seal™

Geir Otto Amundsen on News · Mar 31, 2021

Pipeotech gasket, DeltaV-Seal™ is engineered for long term use, all the way down to applications running at -196°C, based on stellar results of cryogenic leakage tests at a pre-eminent European…

DeltaV-Seal™ - The end to fugitive emissions?

Geir Otto Amundsen on News · Mar 16, 2021

At Pipeotech we believe that the concept of 'acceptable leakage' is unacceptable and that flange-born fugitive emissions are an avoidable threat. As part of our mission to spread this message it was…

Corrosion and integrity specialist Jan Oredsson joins Pipeotech

Geir Otto Amundsen on News · Dec 02, 2020

Pipeotech has sealed the deal on an exciting new addition to its team by bringing in internationally recognized pipeline integrity and corrosion expert Jan Oredsson.Oredsson has extensive experience…

Pipeotech recruits Andrew J. Patrick as new Head of Business Development

Geir Otto Amundsen on News · Oct 05, 2020

Pipeotech is looking to “supercharge” its global growth with the recruitment of Andrew Patrick to the new role of Head of Business Development. Patrick, previously EVP Global Sales at Clock Spring…

Pipeotech joins the European Sealing Association

Geir Otto Amundsen on News · Jun 28, 2020

Pipeotech is pleased to announce that it has become a member of the European Sealing Association.Established in 1992 as a non-profit making trade association, The European Sealing Association…

To boldly go... Pipeotech joins the Innovation Norway, Explorer

Geir Otto Amundsen on News · Apr 22, 2020

We’re pleased to announce that at the beginning of 2020, Pipeotech joined the ranks of one of Norwegian Industry’s most exclusive clubs, The Explorer. Opened by Norwegian Prime Minister Erna Solberg…

The seal of integrity (a feature article written by Industry Networker Magazine)

Geir Otto Amundsen on News · Jul 01, 2019

In a recent article published by Industry Networker Magazine, Pipeotech and theDeltaV-Seal™ are recognized for significant technological enhancements towards safety, efficiency, cost reduction, and…