Cryogenic milestone for DeltaV-Seal™

Geir Otto Amundsen on News · Mar 31, 2021

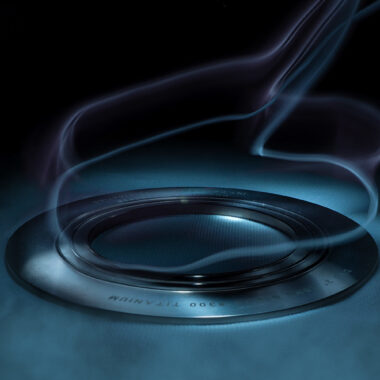

Pipeotech gasket, DeltaV-Seal™ is engineered for long term use, all the way down to applications running at -196°C, based on stellar results of cryogenic leakage tests at a pre-eminent European research lab.

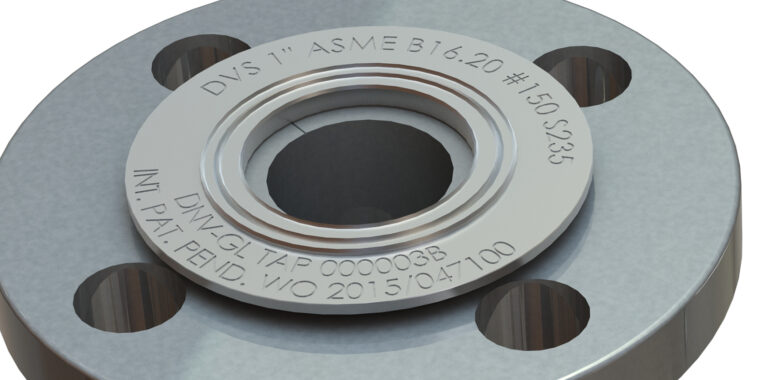

Pipeotech launched its metal-to-metal DeltaV-Seal in 2015. Backed by unique DNV type certification, DeltaV-Seal immediately set a new gas-tight standard for industrial gaskets, offering the first sealing solution that was proven to stay exceptionally tight over time with zero maintenance or retorquing required. After proving its efficacy in sectors ranging from hydrocarbons to chemicals processing, maritime, pharmaceuticals and food and beverage production.

Raising the bar

Pipeotech has now blazed a new trail, conducting leakage testing of a bolted flange joint (BFJ) under cryogenic conditions in a laboratory testing programme engineered and carried out together with Wroclaw University of Science and Technology in Poland. The BFJ contained a DN40/PN40 material 316L DeltaV-Seal with a sealing length of 0.2 metres and containing helium pressures from 10 bar to 100 bar.

“To stand a chance of eliminating fugitive emissions, modern cryogenic processes require a new generation of sealing product that can maintain absolute integrity all the way down to -196°C. The data we have seen is conclusive and should promote DeltaV-Seal right to the top of the pile, we’re delighted with the results,” said Pipeotech CEO Henrik Sollie.

The results show that the DeltaV-Seal maintains a tightness level higher than 10-8mg/s at temperatures down to -196°C at all tested pressures. Take a more detailed look at the test procedure and results in this article.

Hydrogen is key new market

A major part of the gas value chain features cryogenic processes where operating temperatures often approach the temperature of liquid nitrogen (i.e. -196°C). Liquefaction, LNG/LPG shipping and terminals, floating LNG (FLNG) facilities, and regasification are consequently one of Pipeotech’s main markets, but the broad spectrum of existing and emerging industries that also use cryogenic processes can also greatly benefit from using the DeltaVSeal. “These industries include production and handling of emerging new green fuels – particularly hydrogen, where there is a lot of activity right now – as well as ammonia and biofuels,” said Sollie.

Challenging the status quo

The status quo in cryogenic processes has been to use old technology that has been extremely prone to leakage, requiring constant maintenance and replacement of gaskets. The Wroclaw lab carried out exactly the same tests under the same cryogenic conditions on 20 to 30 competing high-performance gaskets with graphite or PTFE sealing components. “The results showed that the DeltaV-Seal is more than 10,000 times tighter at 8 bar, which was the highest applied test pressure for these other gaskets. This clearly puts it in a league of its own,” said Sollie.

An important landmark

“Gaskets have for too long been treated as a disposable afterthought, giving rise to the unacceptable phenomenon of 'acceptable leakage'. The raw performance and ever-expanding value proposition of the DeltaV-Seal, even at extreme temperatures, is challenging that belief with these excellent results becoming another important landmark in our technology development,” said Sollie.

For more information on leakage test comparisons and our warranty, please visit the DeltaV-Seal product page.

More from News

DNV Type Approval Certificate Renewed

James Knights on News · Oct 22, 2024

We're pleased to announce the renewal of our DNV Type Approval, valid until 2029. The DNV GL Type Approval (Certificate TAP000003B) celebrates the testing and dedication to achieving the tightest…

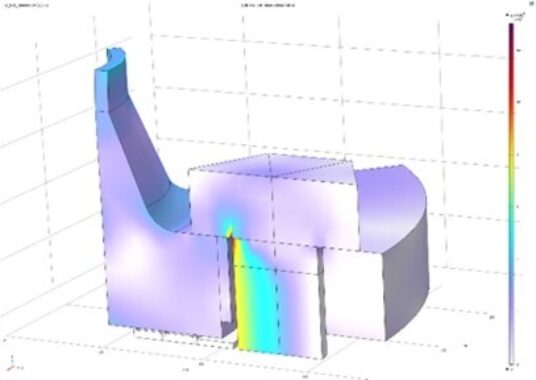

COMSOL Multiphysics FEA Modelling of Gasketed Bolted Flange Joints

James Knights on News · Jul 08, 2024

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's…

Pipeotech launch new 304L stainless steel DeltaV-Seal for nitric acid service

James Knights on News · Jun 21, 2023

Working with the chemical industries it is clear Nitric Acid is a particularly challenging chemical to keep within bolted flange joints. Current industry practice on bolted flange joints containing…

Frequently Asked Questions

James Knights on News · Mar 17, 2023

The DeltaV-Seal is revolutionising static sealing, one gasket at a time. The gasket provides the tightness and durability of a metal-to-metal seal with the ease of application of a spiral wound,…

Proposed European PFAS ban officially submitted – it’s potential impact on PTFE gaskets.

James Knights on News · Mar 17, 2023

On the 13 January 2023, The Netherlands, Germany, Denmark, Sweden and Norway took the first formal step towards a European ban on polyfluoroalkyl substances (PFAS) by jointly submitting a restriction…

We're growing - and moving to a bigger office space!

James Knights on News · Mar 06, 2023

We are excited to announce that Pipeotech’s Oslo team is moving to a new location within Oslo. The big reason? We are growing in both the number of clients and number of applications where a…

DeltaV-Seal Gaskets for peroxide service featured in Fluid Handling Pro

James Knights on News · Dec 21, 2022

Pipeotech's project with a global manufacturer of peroxide has been featured within Fluid Handling Pro. The article details the design considerations for a gasket utilized in an extremely pure…

Pipeotech Q3 Newsletter

James Knights on News · Oct 20, 2022

Another quarter is in the books here at Pipeotech. Q3 brought many opportunities for the company. Engineers and executives met with clients across the globe and attended various events to share the…

Pipeotech, featured in Fluid Handing Pro

Jo Shailes on News · Nov 15, 2021

Vibration Analysis Part of the DNV Type Approval for the Pipeotech DeltaV-Seal The weakest link in industrial piping systems is the gasket. Conventional semi-metallic gasket technologies are not able…

Pipeotech, featured in Sealing Technology & World Pumps

Jo Shailes on News · Oct 27, 2021

Following extensive leakage testing, carried out under cryogenic conditions in a laboratory programme, Pipeotech has extended coverage all the way down to applications running at a temperature of…

Valve World features DeltaV-Seal™

Geir Otto Amundsen on News · Sep 15, 2021

In July 2021, one of the sealing industry's most widely circulated publications, Valve World, featured Pipeotech CTO Jan Oredsson inspecting a DeltaV-Seal gasket on its front cover, hailing Pipeotech…

Andrew Patrick takes over as Pipeotech interim CEO

Geir Otto Amundsen on News · Jun 23, 2021

Pipeotech has appointed Andrew Patrick as the company’s interim chief executive following the resignation of outgoing CEO Henrik Sollie. Patrick steps into the interim role from his current position…

DeltaV-Seal™ - The end to fugitive emissions?

Geir Otto Amundsen on News · Mar 16, 2021

At Pipeotech we believe that the concept of 'acceptable leakage' is unacceptable and that flange-born fugitive emissions are an avoidable threat. As part of our mission to spread this message it was…

Corrosion and integrity specialist Jan Oredsson joins Pipeotech

Geir Otto Amundsen on News · Dec 02, 2020

Pipeotech has sealed the deal on an exciting new addition to its team by bringing in internationally recognized pipeline integrity and corrosion expert Jan Oredsson.Oredsson has extensive experience…

Pipeotech recruits Andrew J. Patrick as new Head of Business Development

Geir Otto Amundsen on News · Oct 05, 2020

Pipeotech is looking to “supercharge” its global growth with the recruitment of Andrew Patrick to the new role of Head of Business Development. Patrick, previously EVP Global Sales at Clock Spring…

Pipeotech joins the European Sealing Association

Geir Otto Amundsen on News · Jun 28, 2020

Pipeotech is pleased to announce that it has become a member of the European Sealing Association.Established in 1992 as a non-profit making trade association, The European Sealing Association…

To boldly go... Pipeotech joins the Innovation Norway, Explorer

Geir Otto Amundsen on News · Apr 22, 2020

We’re pleased to announce that at the beginning of 2020, Pipeotech joined the ranks of one of Norwegian Industry’s most exclusive clubs, The Explorer. Opened by Norwegian Prime Minister Erna Solberg…

From subsea to life on land - gasket technology follows Darwinism

Geir Otto Amundsen on News · Aug 28, 2019

As featured by Yahoo Finance news via Cision PRNewswireMetal-to-metal sealing technology is a technique that had previously been reserved for subsea oil and gas applications where meeting the most…

The seal of integrity (a feature article written by Industry Networker Magazine)

Geir Otto Amundsen on News · Jul 01, 2019

In a recent article published by Industry Networker Magazine, Pipeotech and theDeltaV-Seal™ are recognized for significant technological enhancements towards safety, efficiency, cost reduction, and…