DeltaV-Seal™ solved permanent leakage at processing plant

Jo Shailes on Case Studies · Mar 21, 2019

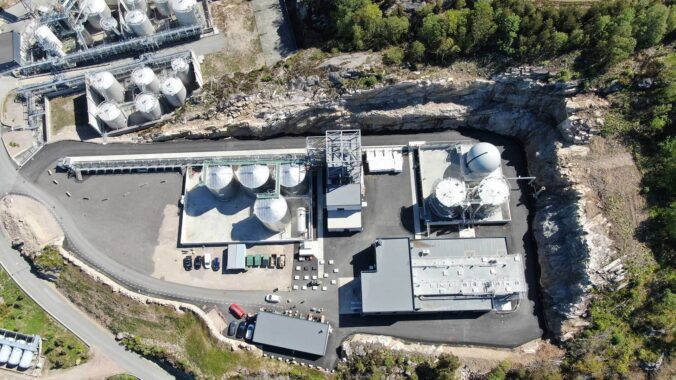

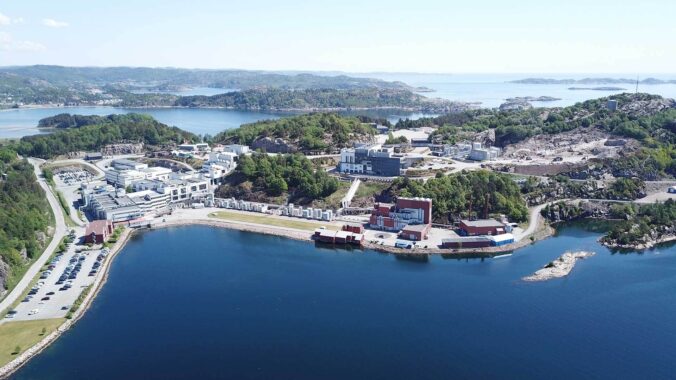

Norway’s key processing plants used for the transportation and processing of gas and condensate/light oil has successfully sealed previously sustained leaks. Located in Kårstø, Norway it is one of the largest of its kind in Europe, it found itself plagued with leaks in its condensed steam piping system. After trying various gasket sealing solutions to stop the leaking flanges, the leaks were completely eliminated through the utilization of the DeltaV-Seal. The DeltaV-Seal offers a gas-tight, metal-to-metal solution that is capable of operating in extreme temperatures without developing deposits on the flanges.

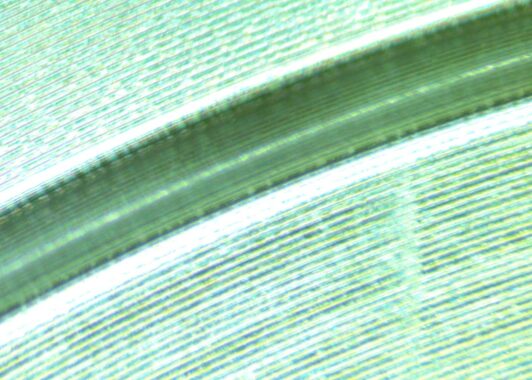

Operating conditions expose gaskets to excessive strain, normally leaving deposits on the flange.

Leakage in piping installations constitute a major challenge at processing plants. High pressure steam, various chemical components, and severe temperature fluctuations put strain on the joint flanges of gasket seals. Even small leaks may cause major problems, as well as power loss and unwanted strain on the pipe system. Leaks may also cause pollution problems detrimental to the plant itself, the working environment, and the surrounding environment.

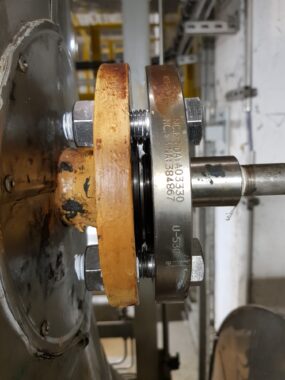

The plant experienced leakage over an extended period of time, despite several attempts which were made to seal the flange using various, competing sealing solutions. However, Tvedestrand based Pipeotech offered to deliver its new and patented DeltaV-Seal seal system to the 18-inch flange, free of charge, enabling the plant operator to test the quality. The DeltaV-Seal was delivered in 316L material, which matched the flange material. Manufacturing the DeltaV-Seal out of the same material as the flange prevents galvanic corrosion from developing, further protecting the flange’s integrity.

Attending the installation of the DeltaV-Seal at the plant was Pipeotech Sales Manager Erlend Berntsen and Chief Technical Officer Frode H. Larssen. Mr Berntsen explained how the core principle of DeltaV-Seal is to make the seal from the same metal as the flange itself, in addition to integrating elevated rings that adapt to the shape of the flange when bolted together.

– Our sealing system proved effective both against gas and liquid leaks, as well as chemical components prone to corroding other sealing solutions. The DeltaV-Seal withstands large temperature variations and does not cause depositing, which is often a challenge when replacing gaskets.

Erlend Berntsen, Direct Sales Manager, Pipeotech AS

When opening the flange to install the DeltaV-Seal, the flange required a time-consuming process of being cleaned of packaging residue and old sealants. The leaking flange was located several meters up on the rig and a mobile crane was required in order to complete the installation process. The process of removing and cleaning the previously failed seal required four mechanics and a security guard to work an entire day to complete before the new seal could be inserted.

The flange the leak was located at a flange several meters up on the rig and a mobile crane was required in order to complete the installation process.

After installation of the DeltaV-Seal was completed a test report confirmed the flange became 'gas-tight' and all leakage was eliminated after the old seal was replaced. Another advantage of the DeltaV-Seals metal to metal design is that it does not require post-tightening or re-torquing of bolts at any time during its operational life cycle. In addition to the successful remedy of the previously persistent leak, thanks to the design of the DeltaV-Seal and ease of installation, the cost of the process was below the estimated cost.

– We are now eager to see if the success of this test will pave the way for the use of our solution in the rest of the plant, as well as in other company installations with leakage issues caused by pressure, vibrations, or temperature fluctuations.

Erlend Berntsen, Direct Sales Manger, Pipeotech AS

For more information, contact us

Contact usMore from Case Studies

DeltaV-Seal increases available up-time on Ammonium Nitrate flanges

James Knights on Case Studies · Sep 16, 2024

Legacy semi-metallic gaskets leak, this is particularly visible on Ammonium Nitrate flanges. The DeltaV-Seal provides a significantly tighter seal than legacy gaskets, enabling fertilizer…

DeltaV-Seal - Preventing emissions of NOX gas during fertilizer manufacture

James Knights on Case Studies · Sep 16, 2024

NOX is considered an indirect greenhouse gas, with strict PPM values for the amount of emissions a chemical plant can release. The DeltaV-Seal with its tight and durable seal prevents emissions of…

DeltaV-Seal - Reducing fugitive emissions in the Permian Basin

James Knights on Case Studies · Jul 22, 2024

The United States Clean Air Act (CAA) is the comprehensive federal law regulating emissions from stationary and mobile sources. Among other things the CAA authorises the United States Environment…

Best Available Technology to reduce ATEX zones, increase reliability, and improve safety within a refinery

James Knights on Case Studies · Jul 21, 2023

Europe’s most advanced refinery wanted to further pioneer by only utilizing Best Available Technology to ensure a safe and reliable operation with minimal impact on the environment, enhanced…

FPSO & Marine - DeltaV-Seals ensure the safe and reliable operation of inert gas systems

James Knights on Case Studies · Mar 21, 2023

A market-leading expert for the maritime industry manufactures a range of inert gas generators to suit their client's needs. Vessels carrying cargo-producing hydrocarbon vapors require inert gas…

Preventing nitrous gas leakage at a Thermowell instrument flange joint

James Knights on Case Studies · Mar 09, 2023

On a Thermowell instrument coupling flange joint a previous semi-metallic gasket required maintenance intervention 7 times in three-and-a-half years. Switching from a semi-metallic gasket to the…

Semi Conductor application for Nitrogen and Oxygen gas purifiers

James Knights on Case Studies · Feb 27, 2023

One of the world's leading semiconductor manufacturers in South Korea required a carbon-free, bacteria and virus-tight gasket capable of withstanding temperatures up to 500°C. The DeltaV-Seal™…

ATEX Zoning reduction & Equipotential bonding possible with the DeltaV-Seal

James Knights on Case Studies · Jan 09, 2023

Recycling metallic canisters containing flammable gases to prevent the emission of the gases to the environment and recycle the metallic packing material.

Reducing ATEX zoning within a biogas plant

James Knights on Case Studies · Nov 11, 2022

Local regulation of a biogas plant in Western Europe required ATEX zoning. Utilizing several technical standards including EN1127, EN1591, and Pipeotech's extensive library of product testing, it has…

Cleaned gaskets within a peroxide system of a chemical processing plant

James Knights on Case Studies · Oct 11, 2022

Ensuring product quality and plant safety with a clean, bespoke, tight, and durable seal. The DeltaV-Seal enabled a manufacturer of peroxide to ensure their product was made safely and was free of…

Corporate environmental responsibility ‘done right’ with long-term methane mitigation by design

Jo Shailes on Case Studies · Nov 02, 2021

Methane is one of the most potent greenhouse gases and avoiding leakage is a priority when using methane systems. Methane also ignites easily, so there are clear and immediate HSE incentives for…

Gasket ensures a long-lasting seal

James Knights on Case Studies · Nov 02, 2021

In manufacturing fertilizer, ammonium nitrate is added to the process, and traditional, spiral wound and Gylon gasket technology often deteriorate in these conditions, resulting in leaks. This is…

ATEX zoning unnecessary with DeltaV-Seal™

Jo Shailes on Case Studies · Nov 01, 2021

During final assembly in the factory, cars are filled with fuel before being transported to their final destination. To facilitate this, fuel lines run throughout the facility. However, along the…

DeltaV-Seal™ stops flammable leakage, prevent fires

Jo Shailes on Case Studies · Nov 01, 2021

In facilities that use hot oil heat transfer fluid systems, fire hazards are a significant challenge due to the combination of organic combustible liquids, which run at temperatures above their flash…

DeltaV-Seal™ prevent fires, promote safe environment

Jo Shailes on Case Studies · Nov 01, 2021

The use of hot oil systems in manufacturing presents challenges when traditional gaskets breakdown and cause leakage. As liquids in the system are kept at a temperature above their flash point, when…

DeltaV-Seal™ prevents leaks and pipe corrosion

Jo Shailes on Case Studies · Nov 01, 2021

In district heating and cooling, generic spiral wound gaskets frequently cannot cope with the cyclical temperature conditions and often fail, leading to leakages and corrosion of the pipeline. This…

DeltaV-Seal™ performs under extreme marine conditions

Jo Shailes on Case Studies · Nov 01, 2021

Importing ship-to-shore Liquefied Natural Gas (LNG) requires robust and efficient pipeline seals that are compliant with high environmental standards. The thermal cycling caused by the cryogenic…

DeltaV-Seal™ reduces greenhouse emissions

Jo Shailes on Case Studies · Nov 01, 2021

In fertilizer production, high-quality phosphorus fertilizers require nitric acid as a key ingredient, which is usually synthesized via the Ostwald process on-site (oxidizing of ammonia before…

In conversation with: Odd Skagestad, GE Healthcare Lindesnes

Geir Otto Amundsen on Case Studies · Jun 02, 2021

We recently spent some time talking with technical engineer Odd Skagestad from GE Healthcare Lindesnes about how DeltaV-Seal™ technology has impacted operations at a world-leading pharmaceutical…

Pipeotech’s reach goes atomic

Geir Otto Amundsen on Case Studies · Jan 05, 2021

Pipeotech has taken gasket tightness to new microscopic levels by supplying DeltaV-Seal™ to European Spallation Source, the world’s most powerful neutron source, in Lund, Sweden. The new research…

VARD finds the perfect fit

Jo Shailes on Case Studies · Nov 11, 2020

Norwegian-based shipbuilder VARD has been installing Pipeotech’s DeltaV-Seal™ in its vessels since 2016 and the cost-saving benefits have been very clear to Johny Morland, Principal Engineer, QA and…

Corrosive influence - The dangers of galvanic corrosion for pipelines

Geir Otto Amundsen on Case Studies · Apr 22, 2020

Prevention is always better than a cure. Avoiding issues in the first place, rather than attending to them once they’ve occurred, is plain common sense. So why do so many industrial facilities…

Pipeline safety – How gasket choices can mitigate health and safety risks

Geir Otto Amundsen on Case Studies · Jan 31, 2020

Nothing is as important as health and safety when it comes to industrial facilities. However, a critical component in piping systems is often overlooked, viewed as a consumable rather than a key to…

Stopping expensive leakages at historic brewing facility

Geir Otto Amundsen on Case Studies · Jan 31, 2020

With the title of ‘the oldest brewery in Norway’, the Aass brewery is about as close as it gets to being a Norwegian institution. Situated on the banks of the river in the busy port city of Drammen…

DeltaV-Seal™ replaces kammprofile gaskets at critical distribution facility

Jo Shailes on Case Studies · Jun 12, 2019

After a long relationship utilizing kammprofile gasket technology, Norwegian LPG distributor PrimaGaz Norge AS has decided to abandon the old kammprofile gasket design in favor of the new DeltaV-Seal…

Flare tip leakage is too hot to handle for the competition

James Knights on Case Studies · May 15, 2019

Pipeotech was called upon to provide a solution for Flare Tip flange leak in the North Sea. A North Sea Operator came to Pipeotech with a problem affecting a Flare line on their platform. This was…

Exceeding gas-tight sealing strengths and eliminating ATEX zones

Geir Otto Amundsen on Case Studies · May 08, 2019

Gaskets seals are generally the consumables often selected at the last moment in a design project and carry few expectations. Although viewed as less significant, this consumable can have the most…